A heat treatment method for extra-thick, extra-wide, and extra-long chromium-molybdenum steel plates

A heat treatment method and steel plate technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as difficulty in ensuring uniformity of heating, constraints on petrochemical development, and difficulty in meeting technical conditions for the uniformity of performance of the entire steel plate. Improve the performance of the whole board and the qualified rate of performance, prolong the swing time, and have obvious technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The grade of the chromium-molybdenum steel plate in this embodiment is 14Cr1MoR, the thickness of the steel plate is 88 mm, the width is 3300 mm, and the length is 14500 mm.

[0017] The heat treatment method of the chromium-molybdenum steel plate of the present embodiment includes heating and water cooling, and the specific process steps are as follows:

[0018] (1) Heating process: Furnace a single piece of steel plate, heat the single piece to 900°C and keep it warm for 3.2 hours, and raise the furnace temperature by 5°C 30 minutes before tapping.

[0019] (2) Water cooling process: The water cooling process is carried out immediately after heating, the roller speed is 0.02m / s, and the quenching water volume is 8400m 3 / h, the water temperature is 26°C, the water pressure is 0.75MPa, and the low-pressure section swings for 30 minutes.

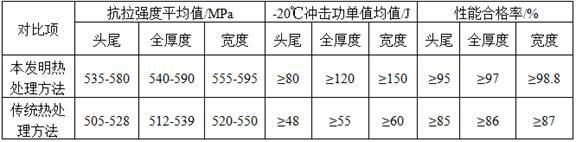

[0020] After the above process, the performance of the whole plate and the pass rate of the performance after 28h long-term mold we...

Embodiment 2

[0022] The grade of the chromium-molybdenum steel plate in this embodiment is 14Cr1MoR, the thickness of the steel plate is 90 mm, the width is 3350 mm, and the length is 14700 mm.

[0023] The heat treatment method of the chromium-molybdenum steel plate of the present embodiment includes heating and water cooling, and the specific process steps are as follows:

[0024] (1) Heating process: Furnace a single piece of steel plate, heat the single piece to 905°C and keep it for 3.3 hours, and raise the furnace temperature by 6°C 32 minutes before tapping.

[0025] (2) Water cooling process: The water cooling process is carried out immediately after heating, the roll speed is 0.03m / s, and the quenching water volume is 8450m 3 / h, the water temperature is 26.5°C, the water pressure is 0.77MPa, and the low-pressure section swings for 30.5min.

[0026] After the above process, the performance of the whole plate and the pass rate of the performance after 28h long-term mold welding of...

Embodiment 3

[0028] The grade of the chromium-molybdenum steel plate in this embodiment is SA387Gr11CL2, the thickness of the steel plate is 92 mm, the width is 3380 mm, and the length is 14800 mm.

[0029] The heat treatment method of the chromium-molybdenum steel plate of the present embodiment includes heating and water cooling, and the specific process steps are as follows:

[0030] (1) Heating process: Furnace a single piece of steel plate, heat the single piece to 910°C and keep it warm for 3.4 hours, and raise the furnace temperature by 7°C 33 minutes before tapping.

[0031] (2) Water cooling process: The water cooling process is carried out immediately after heating, the roll speed is 0.04m / s, and the quenching water volume is 8490m 3 / h, the water temperature is 27°C, the water pressure is 0.80MPa, and the low-pressure section swings for 31min.

[0032] After the above process, the performance of the whole plate and the pass rate of the performance after 28h long-term mold weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com