Preparation technology of suede leather

A preparation process and technology for suede leather, applied in the field of synthetic leather, can solve the problems of suede leather being harmful to human health, poor hand feeling, not soft suede leather, etc., and achieve the effects of smooth surface, uniform pile length and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

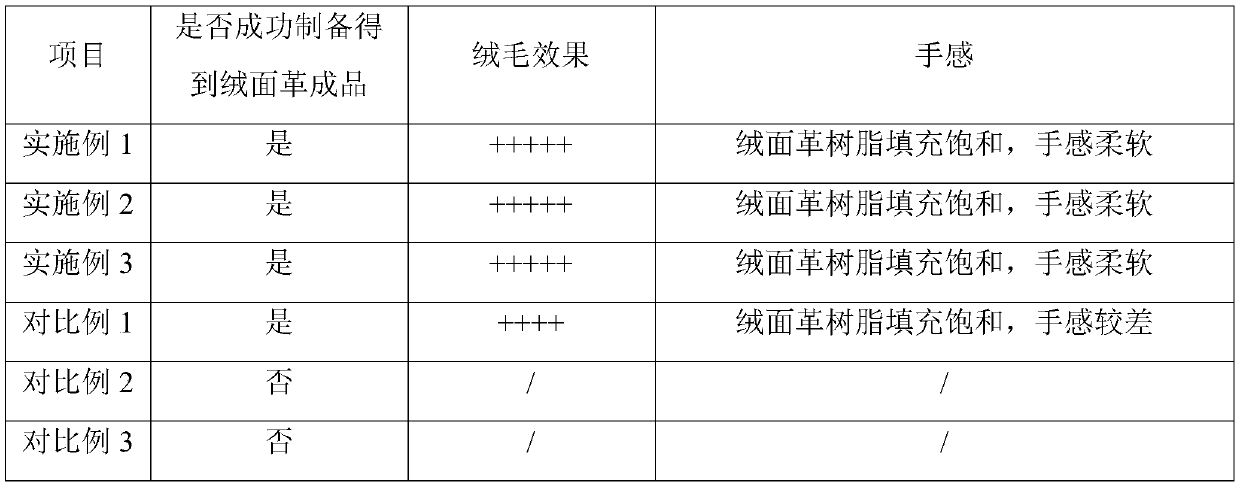

Examples

Embodiment 1

[0031] Example 1: A preparation process of suede leather, including the following preparation steps:

[0032] 1) Preparation of non-woven fabric base fabric: the non-woven fabric for bass is made by using fixed island-type sea-island fibers through cotton opening, carding, netting, needle punching reinforcement and ironing, and the non-woven fabric for bass has a weight of 500g / m 2 , The density is 0.26g / cm 3 , The thickness is 1.8mm;

[0033] 2) Resin impregnation: 80 parts of multi-OH-based prepolymer JF-NS-6011A, 20 parts of multi-NCO-based prepolymer JF-NS-6011B, 2 parts of trimethylolpropane, 4 parts of MSH-550 hollow foam Microspheres, 30 parts of calcium powder, 1 part of Tego Flow 300 leveling agent, 4 parts of color paste are mixed, stored at 30°C at a constant temperature and reacted to a viscosity of 35000mPa·s to obtain a polyurethane prepolymer impregnated slurry, and then the polyurethane is prepolymerized The body impregnation slurry is impregnated in the non-woven...

Embodiment 2

[0038] Embodiment 2: A preparation process of suede leather, including the following preparation steps:

[0039] 1) Preparation of non-woven fabric base fabric: use fixed island-type sea-island fibers through opening, carding, netting, needle-punch reinforcement and ironing processes to make a non-woven fabric for bass. The non-woven fabric for bass has a weight of 400g / m 2 , The density is 0.2g / cm 3 , The thickness is 1.6mm;

[0040] 2) Resin impregnation: 70 parts of multi-OH-based prepolymer JF-NS-6011A, 15 parts of multi-NCO-based prepolymer JF-NS-6011B, 3 parts of trimethylolpropane, 3 parts of MSH-550 hollow foam Microspheres, 25 parts of montmorillonite, 2 parts of Silok 355 leveling agent, 4 parts of color paste are mixed, and the reaction is stored at 25°C at a constant temperature until the viscosity is 40000mPa·s to obtain polyurethane prepolymer impregnated slurry, and then the polyurethane is prepolymerized The body impregnation slurry is impregnated in the non-woven...

Embodiment 3

[0045] Embodiment 3: A preparation process of suede leather, including the following preparation steps:

[0046] 1) Preparation of non-woven fabric base fabric: use fixed island-type sea-island fibers through opening, carding, netting, needle-punch reinforcement and ironing processes to make bass non-woven fabric, the bass non-woven fabric gram weight is 600g / m 2 , The density is 0.32g / cm 3 , The thickness is 2.2mm;

[0047] 2) Resin impregnation: 90 parts of multi-OH-based prepolymer JF-NS-6011A, 25 parts of multi-NCO-based prepolymer JF-NS-6011B, 4 parts of trimethylolpropane, 2 parts of MSH-550 hollow foam Microspheres, 35 parts of wood powder, 1 part of Silok 8230 leveling agent, 2 parts of color paste were mixed, stored at 20°C at a constant temperature and reacted to a viscosity of 45000mPa·s to obtain polyurethane prepolymer impregnated slurry, and then polyurethane prepolymer The impregnated slurry is impregnated in the non-woven fabric for bass;

[0048] 3) Shaping: Heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com