Detection equipment with powder fluidity characterization device

A technology of testing equipment and fluidity, which is applied in the field of 3D printing, can solve the problems of far difference between measurement results and actual use conditions, differences, large measurement errors, etc., and achieve the effects of easy use and promotion, high measurement accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

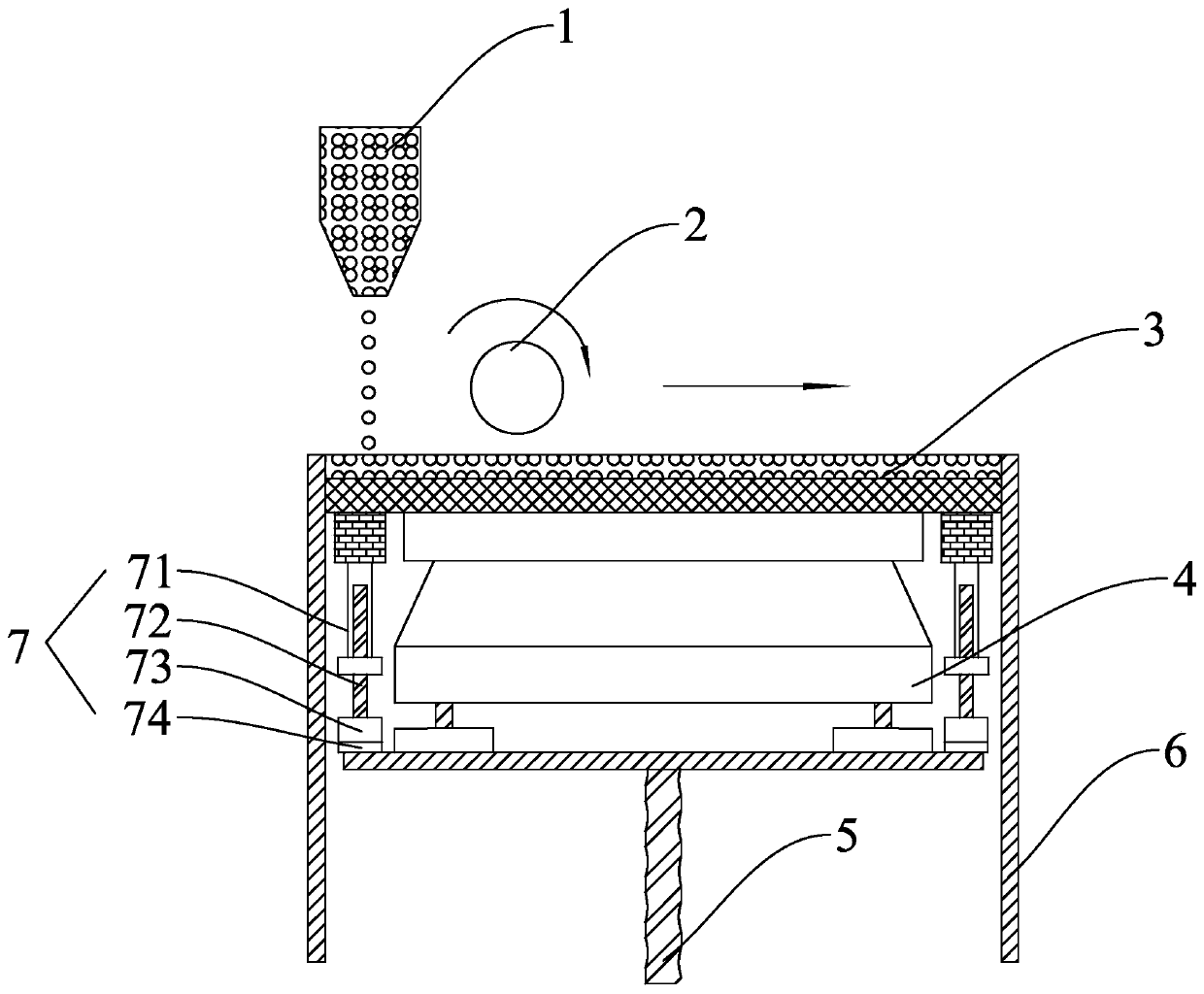

[0046] Such as figure 1 As shown, a detection device with a powder fluidity characterization device includes a powder tank 6, a powder bed 3 that moves up and down along its inner wall is arranged in the powder tank 6, and a powder bed for supplying powder is arranged above the powder bed 3 . The bucket 1 is provided with a valve for opening and closing at the bottom of the funnel 1. The structure of the valve is a prior art, and will not be repeated here.

[0047] A powder scraping mechanism 2 for paving the powder is arranged above the powder bed 3 at the same time. The powder scraping mechanism 2 can be a drum-type structure. The drum-type structure has a moving shaft and a rotating roller rotating around the shaft. This structure is a conventional design. Therefore, it is not shown in detail in the drawings.

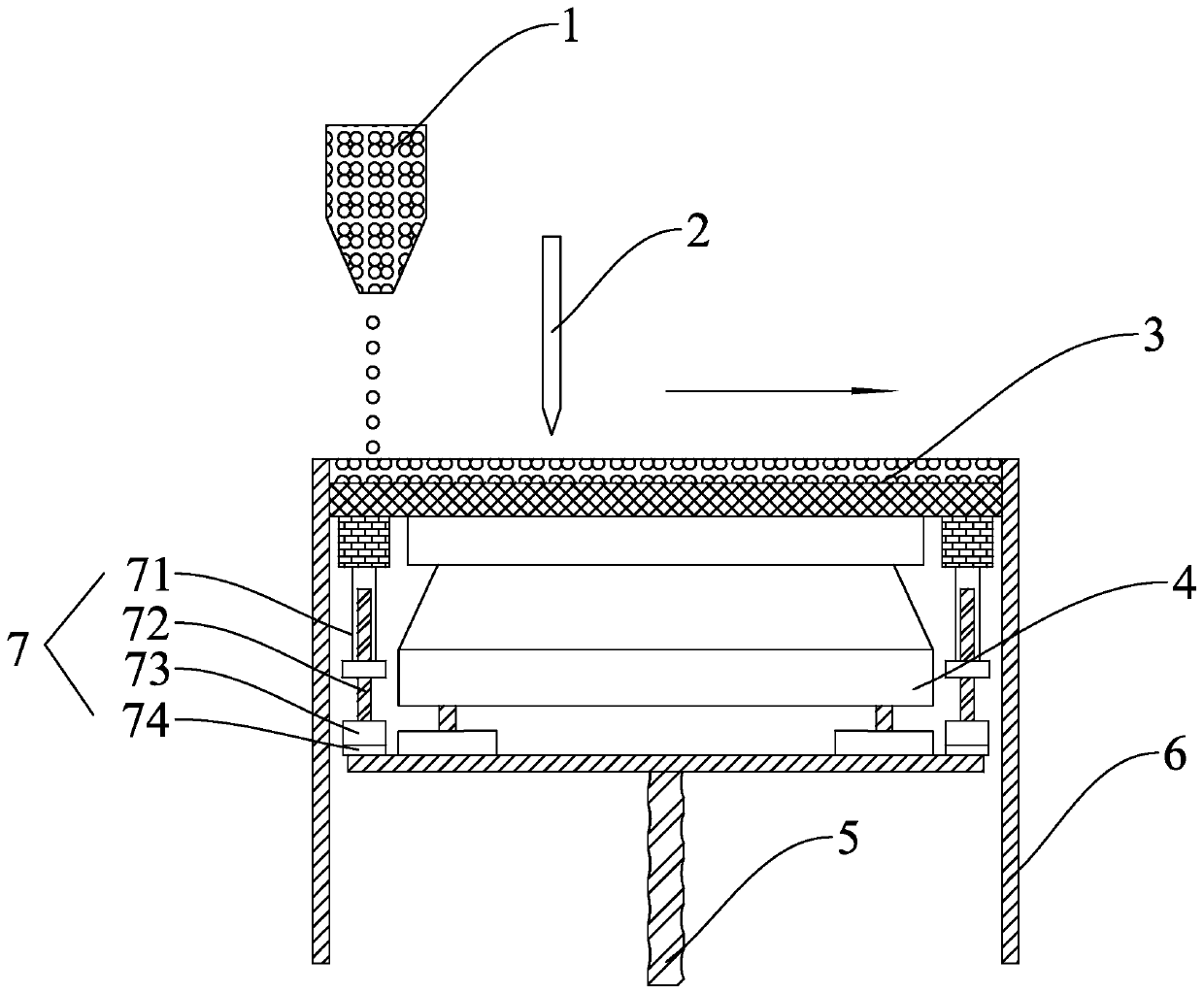

[0048] As another alternative, the above-mentioned powder scraping mechanism 2 can also choose a scraper structure, such as figure 2 As shown, the structure is al...

Embodiment 2

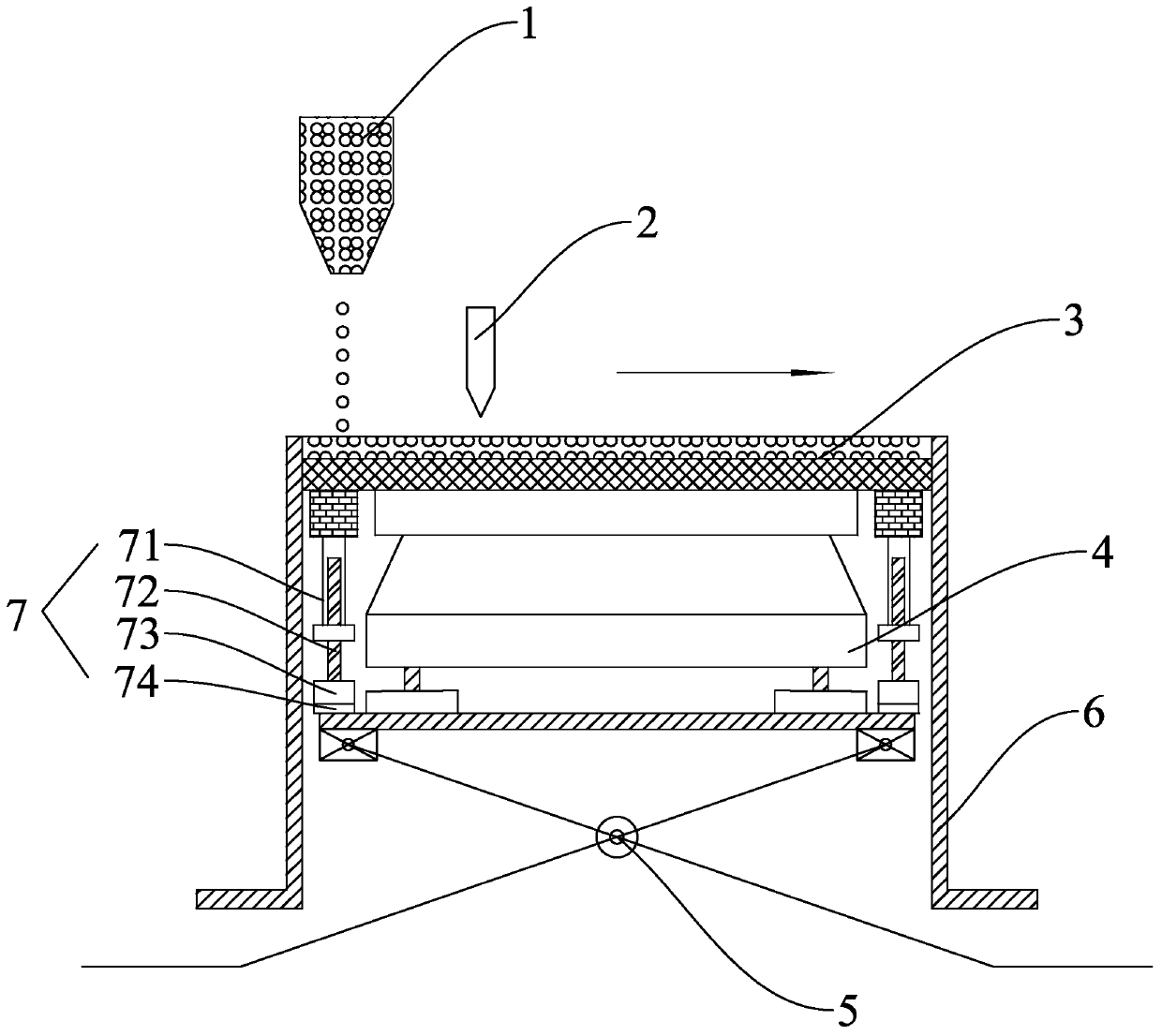

[0057] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 is that a powder hopper 1 is arranged on both sides above the powder bed 3, so as to increase the supply rate of powder materials.

[0058] Working process of the present invention:

[0059] Start the detection equipment, click the reset button, at this time the powder bed 3 returns to the initial position first, then the powder scraping mechanism 2 returns to the initial position, unlock the locking state of the locking mechanism 7, measure the weight of the powder bed 3 at this time, press Reset operation button, the powder weight is reset;

[0060] Start the locking mechanism 7, slowly lift the powder bed 3 from the mass sensor 4 for a certain distance, and then lock the powder bed 3;

[0061] Start to spread the powder, and the powder material will leak to the powder bed 3 through the valve at the bottom of the hopper 1 under the action of gravity, and then spread the powder on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com