System and method for detecting tab welding quality of flexibly-packaged battery cell module

A battery module and tab welding technology, which is applied to battery pack parts, welding equipment, non-electric welding equipment, etc., can solve the problem of affecting the production rhythm of the module, the operator is prone to fatigue, and the low efficiency of manually tilting the edge of the tab to observe and other issues to achieve the effect of ensuring production tempo, reducing procedures and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

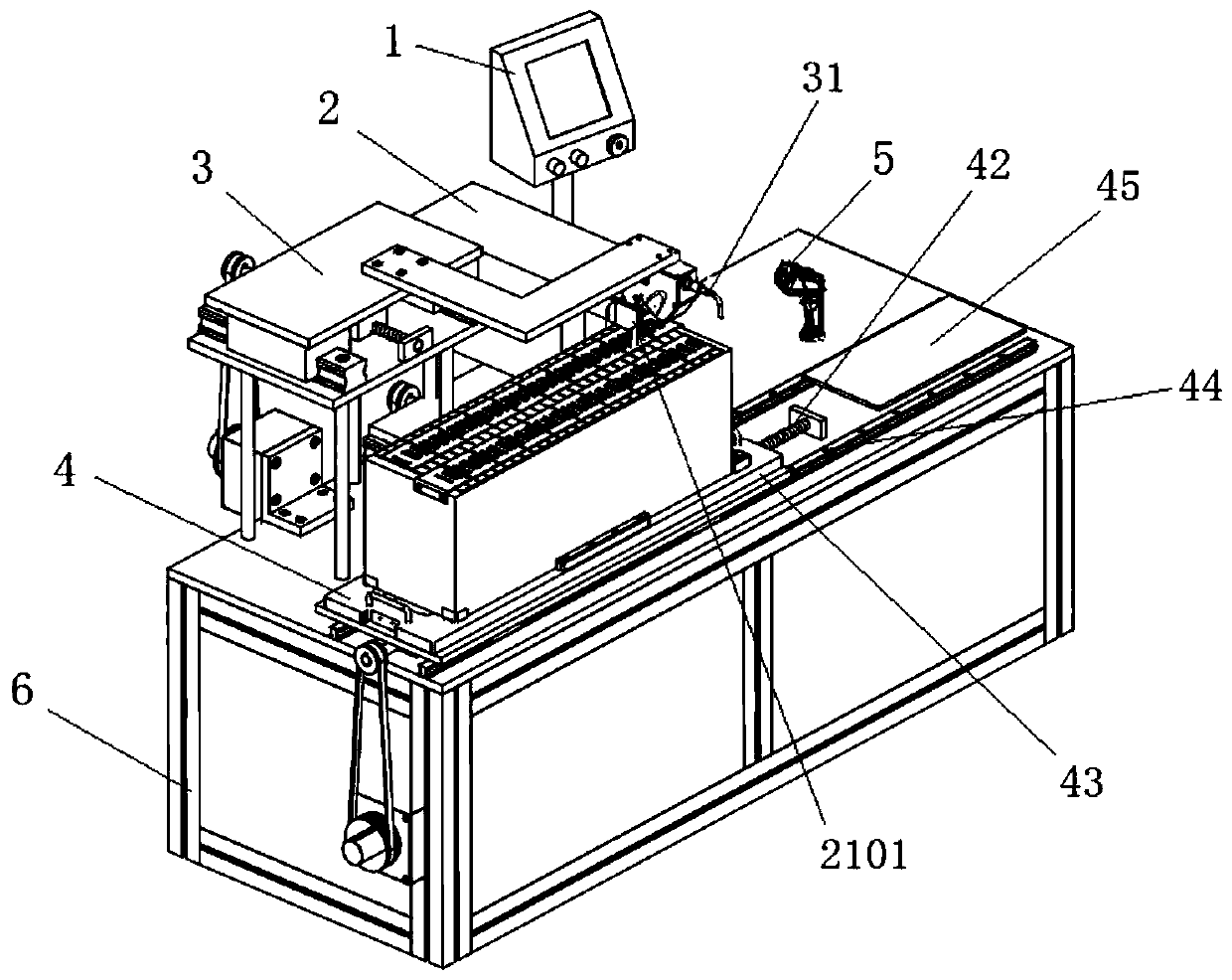

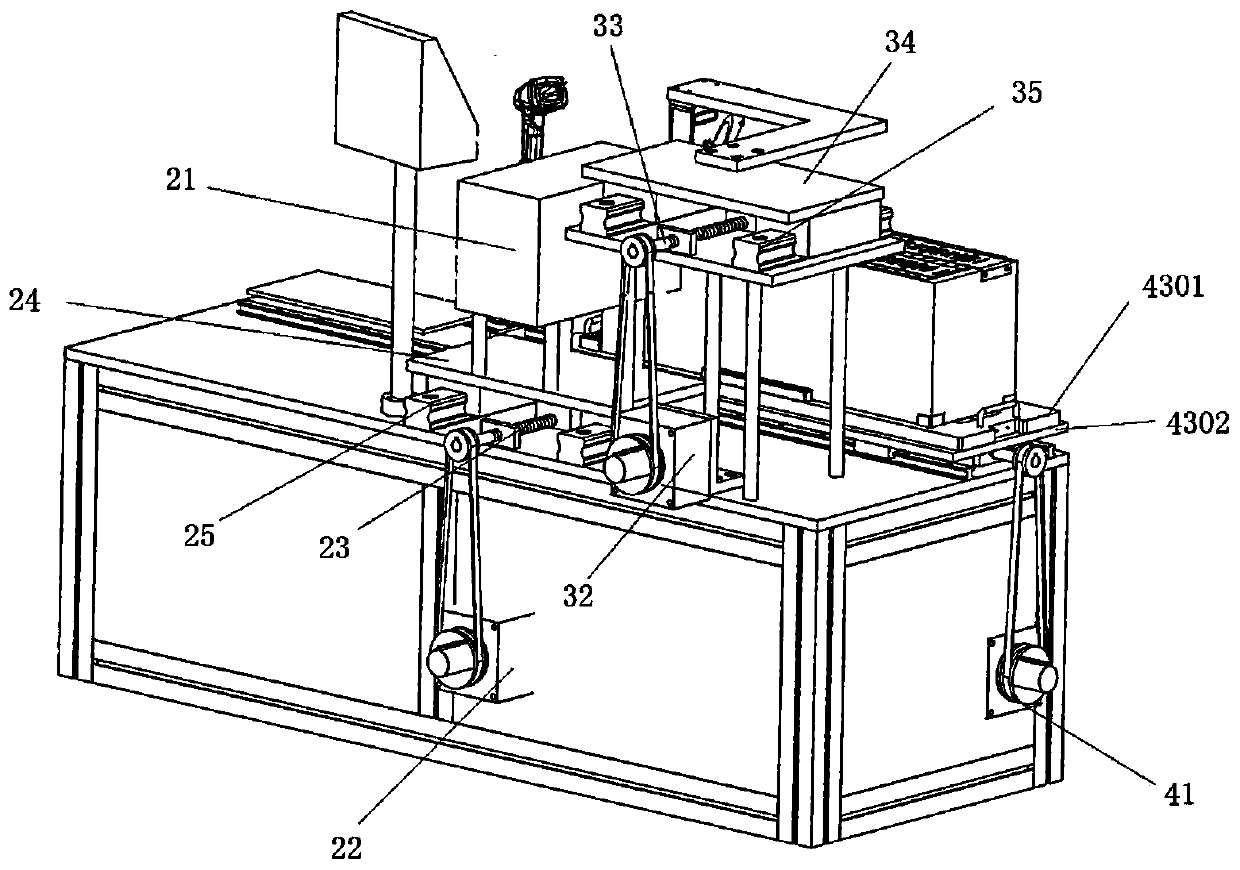

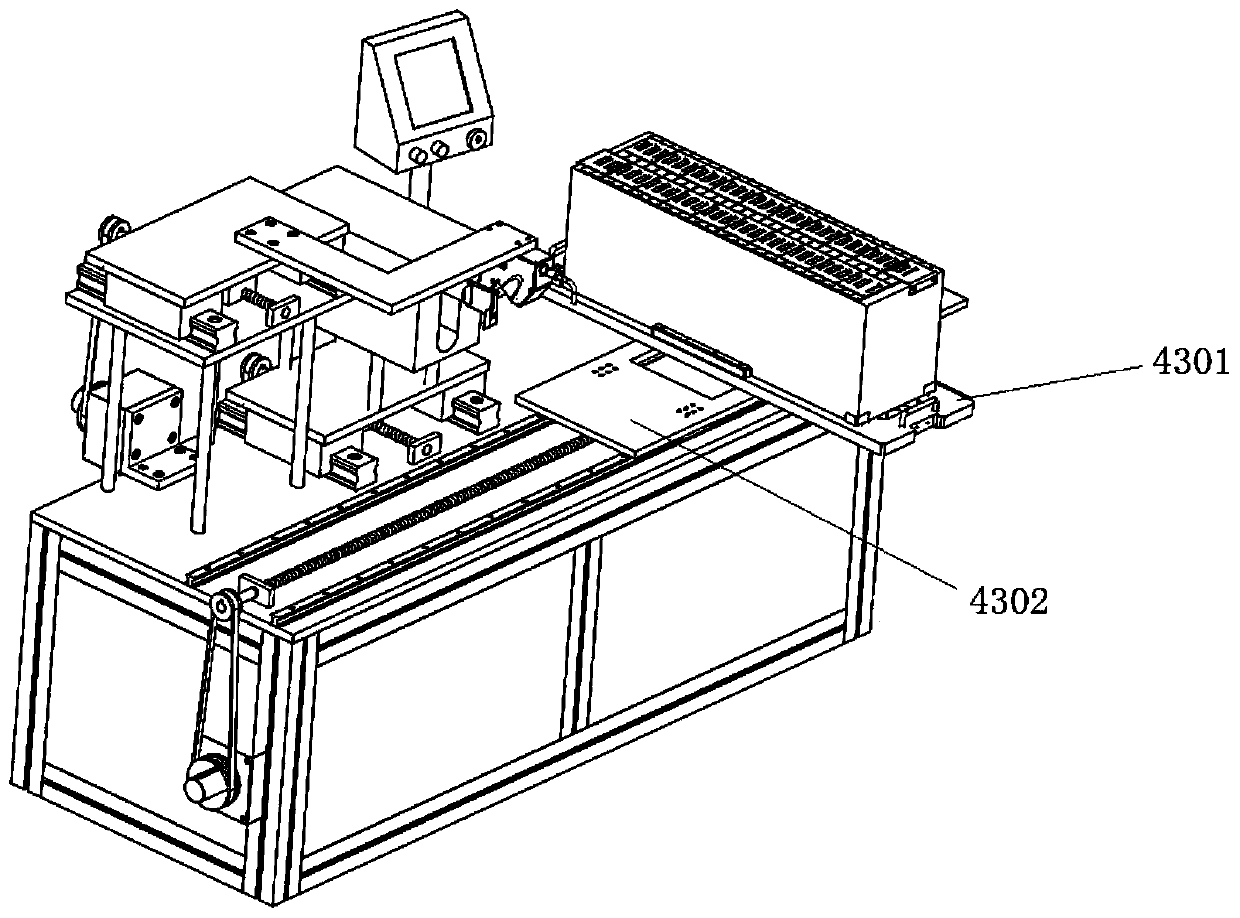

[0028] A soft package cell battery module tab welding quality inspection system, such as Figure 1-2 As shown, it includes a machine platform 6, a battery module walking assembly 4, a vibrating assembly 2, a detection assembly 3, a code scanning gun 5 and a host computer 1, and the battery module walking assembly 4, the vibrating assembly 2, and the detection assembly 3. The code scanning guns 5 are all connected to the host computer. The first guide rail 44 is arranged on the machine platform, the vibrating assembly 2 and the detection assembly 3 are installed on the same side of the first guide rail 44, the ultrasonic welding machine horn 2101 in the vibrating assembly 2 and the wire The sensor heads 31 of the laser measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com