Small feature point visual tracking and real-time quality test device for sheet steel weld joints

A technology for visual inspection and real-time quality, applied in measuring devices, auxiliary devices, optical devices, etc., can solve the problems of high installation accuracy of binocular vision system, inability to complete real-time welding real-time inspection, and unsuitable for complex weld shapes. , to achieve the effect of improving welding accuracy and efficiency, saving welding time and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below, but the scope of the present invention cannot be limited thereto. Any replacement, combination, and separation of components known in the technical field to the mechanism of the present invention, as well as equivalent changes or replacements to the implementation steps of the present invention that are well known in the technical field are within the disclosure and protection scope of the present invention.

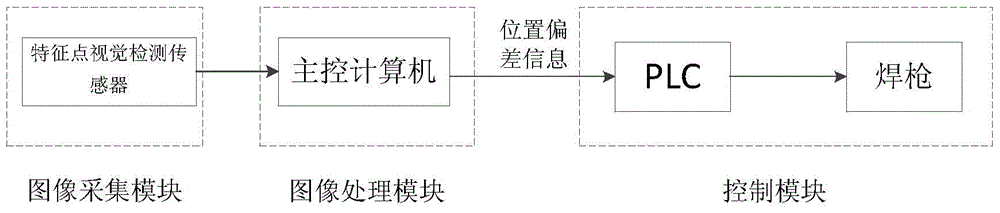

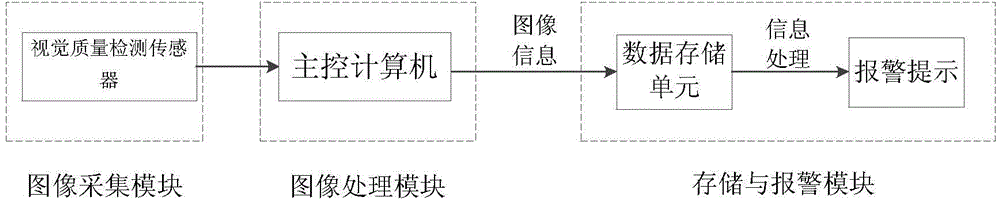

[0026] A visual tracking and real-time quality inspection device for small feature points of thin steel plate welds, the device includes a main control computer, PLC, motor and sensing parts;

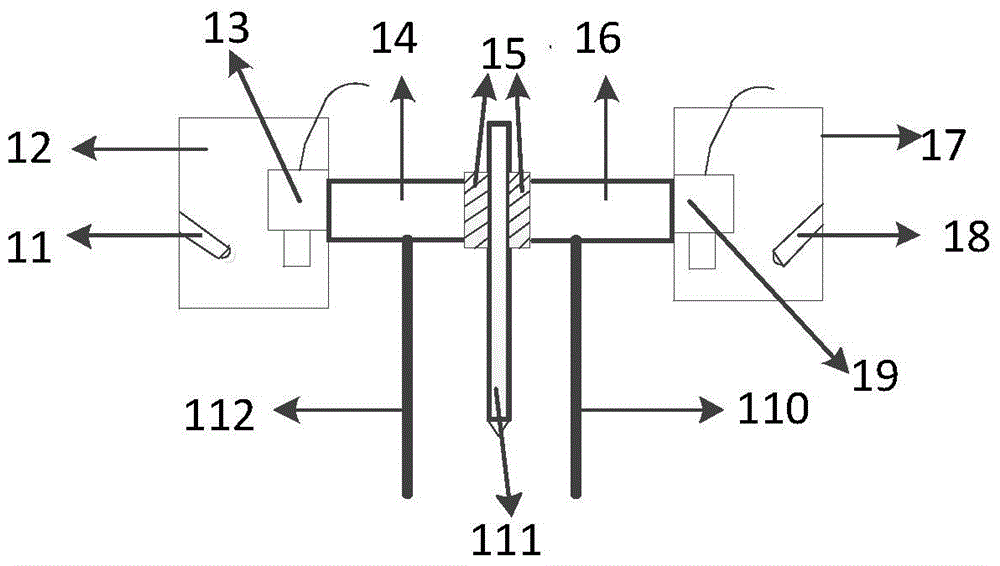

[0027] Described sensing part mainly comprises welding torch 111, and the feature point visual detection sensor 17 of welding torch 111 left and right sides and visual quality detection sensor 12, and wherein welding torch 111 both sides are each rigidly connected with a connecting block 15; A connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com