Ru-based catalyst based on association hydrogenation and chemical-looping synthetic ammonia path as well as preparation method and application of Ru-based catalyst

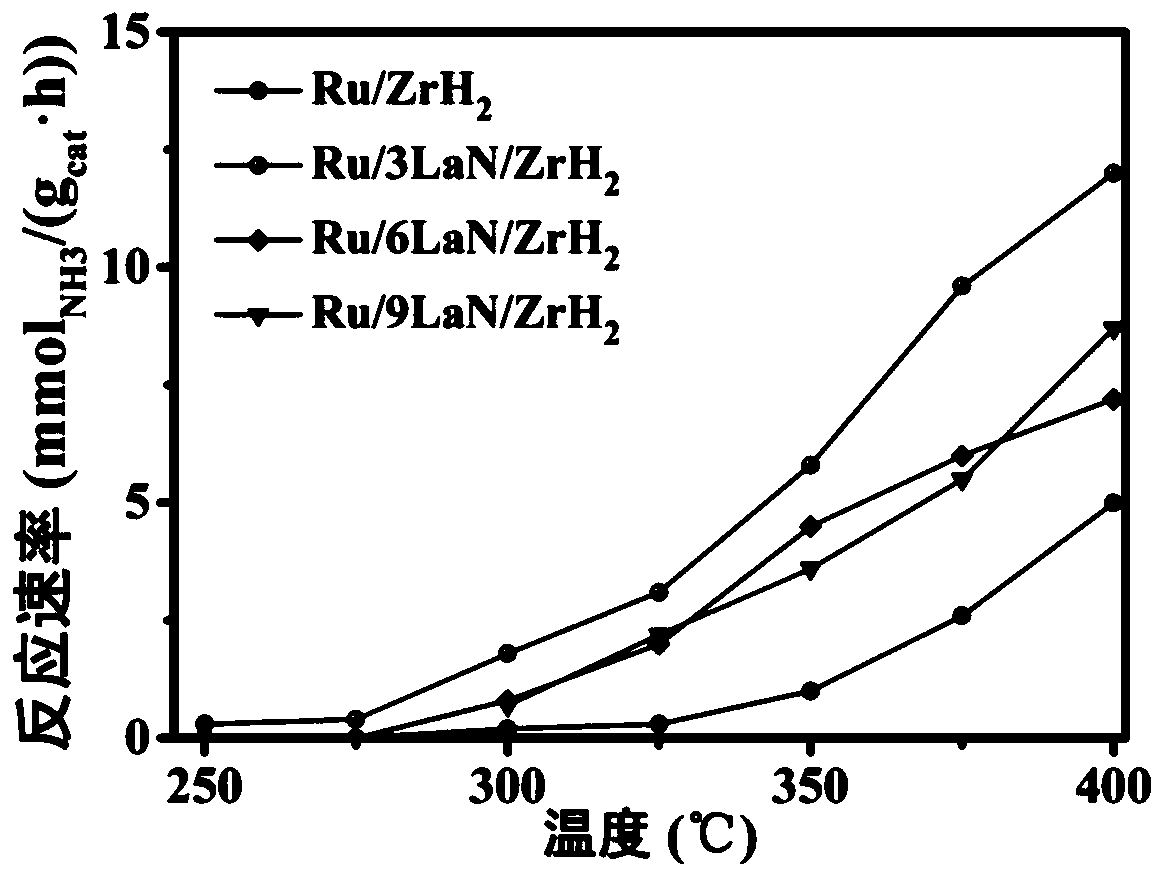

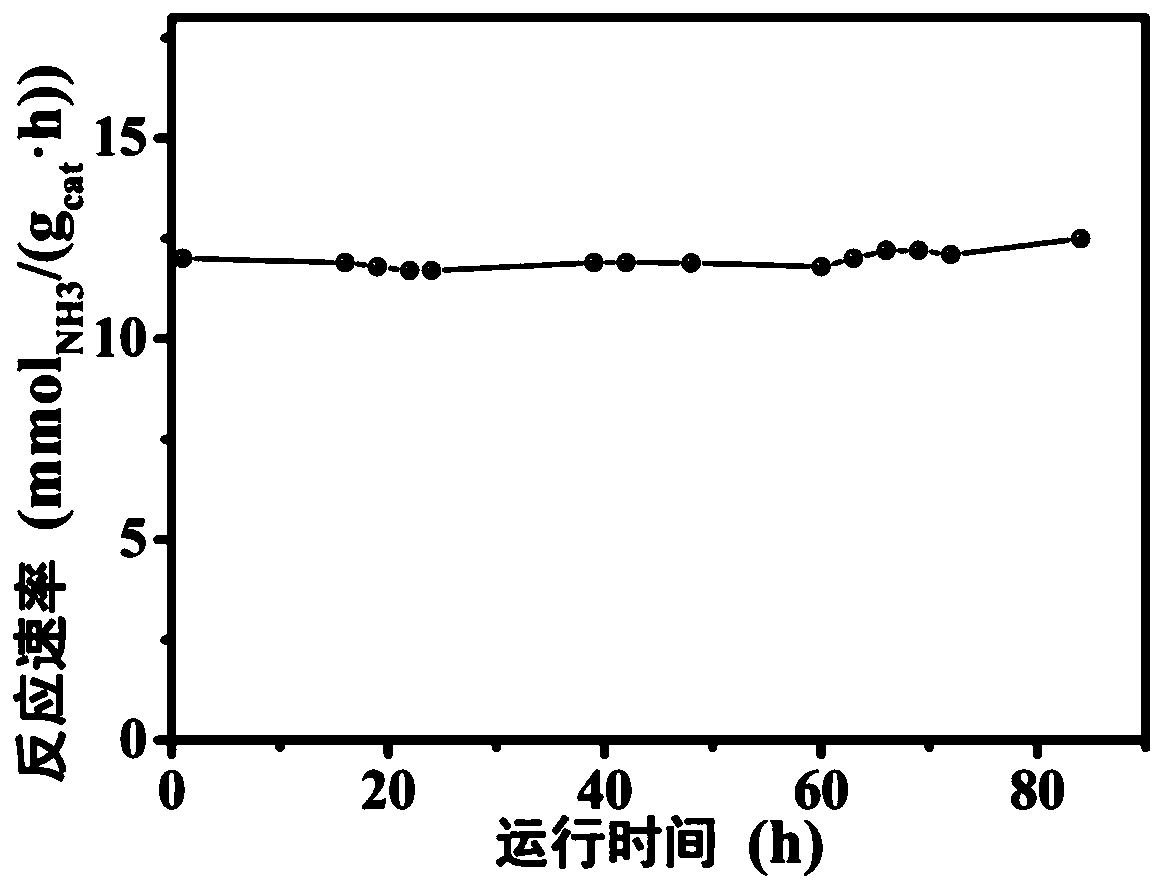

A technology of catalyst and zirconium hydride, which is applied in the direction of physical/chemical process catalysts, preparation/separation of ammonia, chemical instruments and methods, etc., can solve the problems such as the reduction of the equilibrium conversion rate of ammonia synthesis reaction, and achieve obvious industrial application value, good ammonia Synthetic performance and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

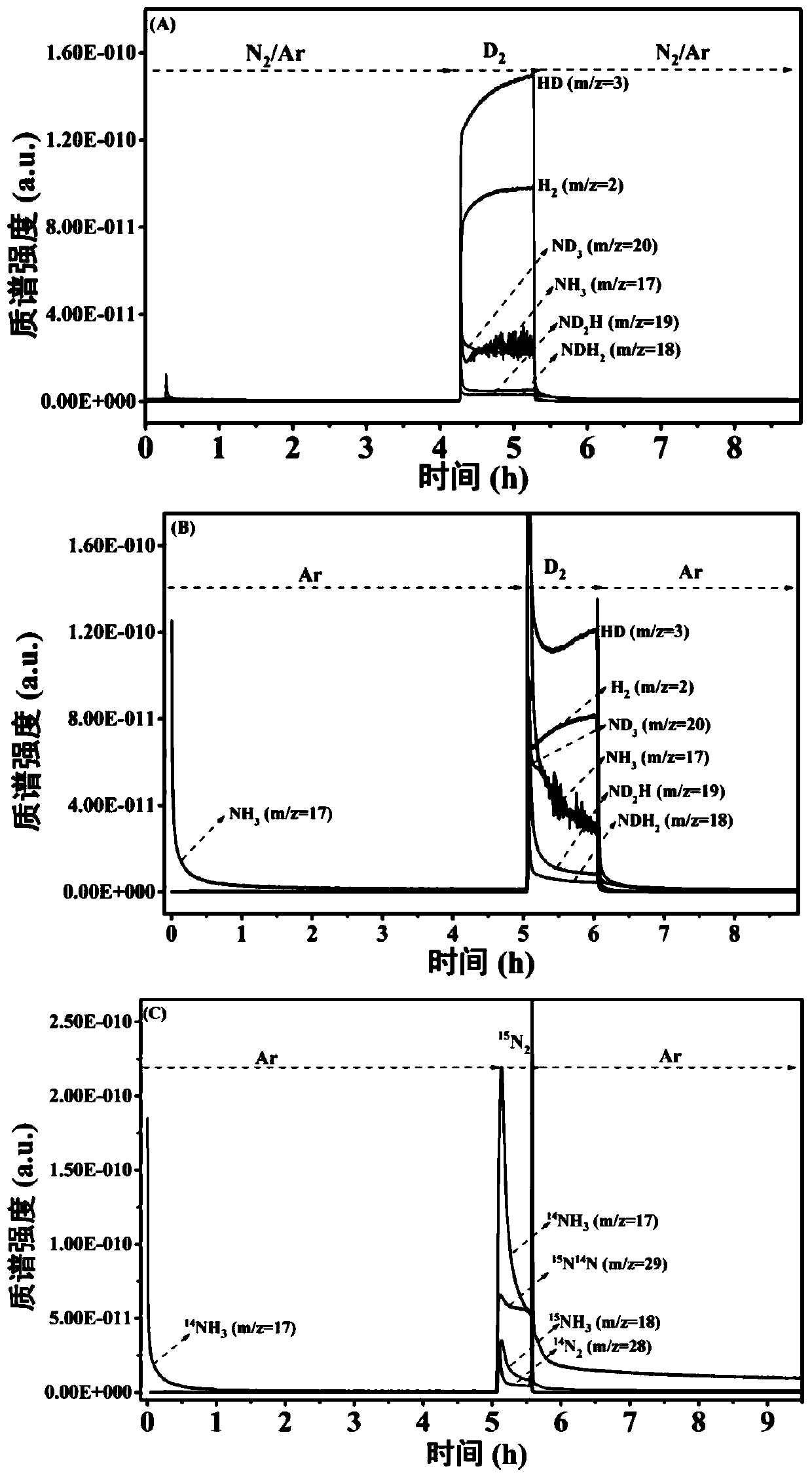

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Ru / ZrH 2 preparation of

[0029] Weigh 1g ZrH 2 , first wet the dry ZrH with water 2 powder, determination of ZrH 2 Pore volume (0.2 mL / g). An aqueous solution of ruthenium nitrosyl nitrate (1.36 mL, w / v=1.5%) was loaded on ZrH 2 powder, impregnated with aqueous ruthenium nitrosyl nitrate to fill the ZrH 2 Pores to fully load Ru on the carrier. Each impregnation (about 0.34 mL) was followed by drying at 80 °C for 8 h until all the water from the impregnation evaporated. Finally, grind and mix evenly in a mortar, transfer the obtained solid powder to a vacuum oven, and dry at 80°C for 12 hours to obtain the catalyst Ru / ZrH 2 .

Embodiment 2

[0031] Ru / 3LaN / ZrH 2 preparation of

[0032] 1g Ru / ZrH 2 Add the powder and 0.0316g LaN into the mortar, and mix them evenly during continuous grinding. After fully mixing, the obtained solid powder is transferred to a vacuum drying oven and dried at 80°C for 12h to obtain the catalyst Ru / 3LaN / ZrH 2 (LaN accounted for 3% of the total catalyst weight).

Embodiment 3

[0034] Ru / 6LaN / ZrH 2 preparation of

[0035] 1g Ru / ZrH 2 Add the powder and 0.0652g LaN into the mortar, and mix them evenly during continuous grinding. After fully mixing, the obtained solid powder is transferred to a vacuum drying oven and dried at 80°C for 12h to obtain the catalyst Ru / 6LaN / ZrH 2 (LaN accounted for 6% of the total catalyst weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com