Electric heating type urea liquid level sensor

An electric heating type, urea solution technology, applied in heat storage heaters, fluid heaters, liquid level indicators, etc., can solve the problems of high cost, slow thawing speed, and foreign matter, and achieve low cost and speed up thawing The speed, the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

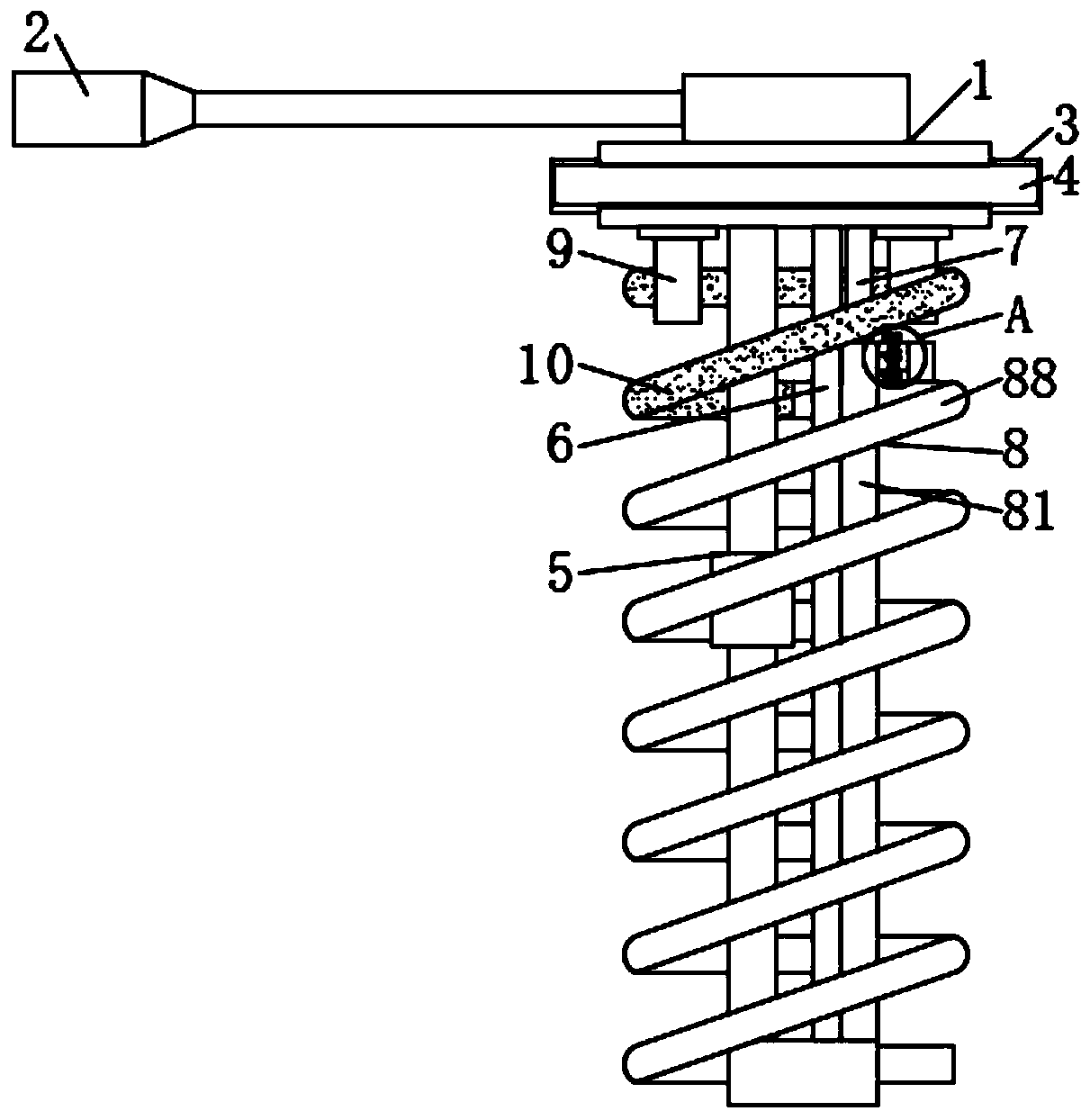

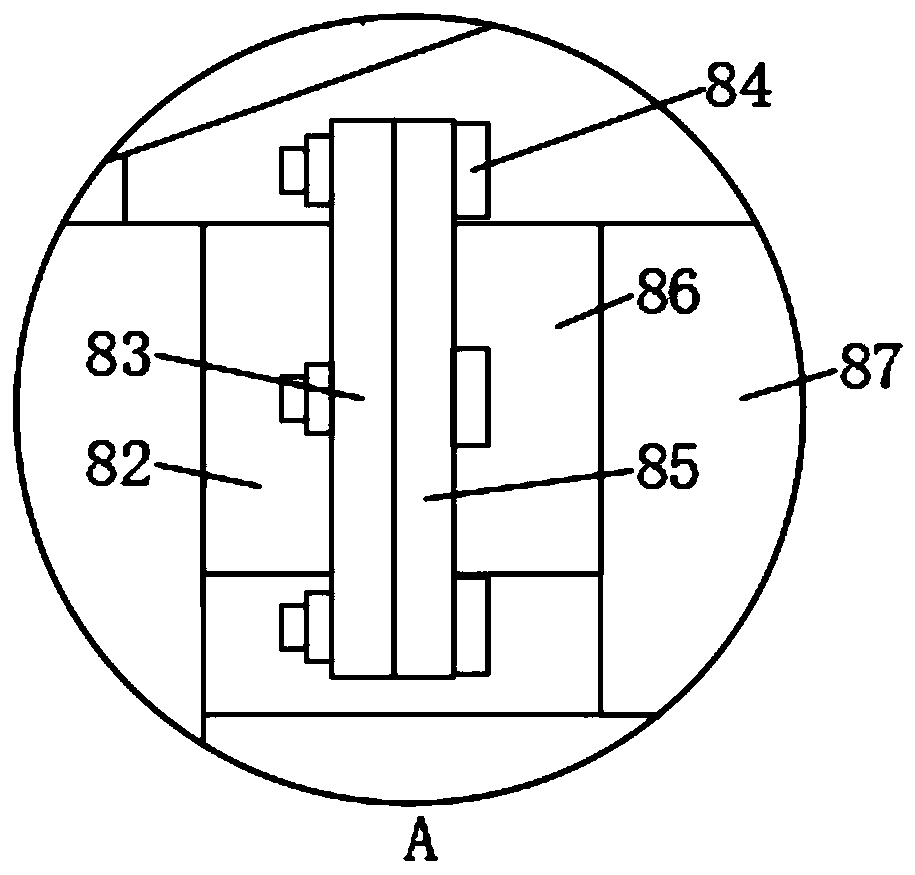

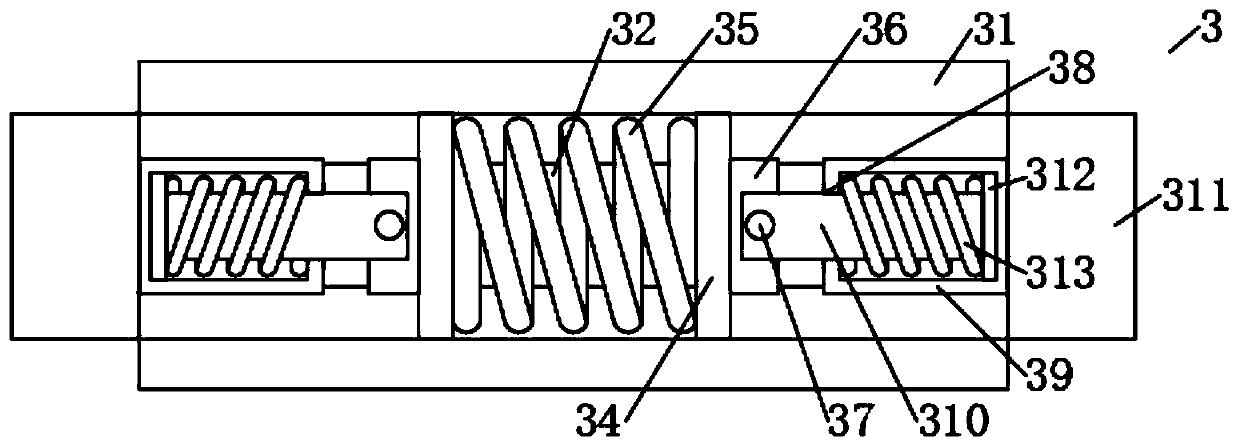

[0026] Example: such as Figure 1-5 As shown, an electric heating type urea liquid level sensor of the present invention includes an upper seat 1, the upper end of the upper seat 1 is fixedly connected with a power cord 2, and the front and rear parts of the upper seat 1 are equipped with a handle 4 through a connecting mechanism 3. The handles 4 are in a U-shaped structure, and the lower end of the upper base 1 is fixedly connected with a sensor assembly 5, a catheter tube 6 and a heating tube 7, and a heat conduction mechanism 8 is installed on the heating tube 7, and the lower end of the upper base 1 is installed by Mechanism 9 is connected with installation tube 10, and described installation tube 10 is helical and is made of heat insulating material, and described installation tube 10 wraps the outside of sensor assembly 5, catheter tube 6 and heating tube 7, and can pass through installation tube 10 The installation of the heat conduction mechanism 8 is reinforced to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com