Novel laser scanning projection method

A laser scanning and projection technology, applied in the direction of using optical devices, image data processing, measuring devices, etc., can solve the problems of long operation time, reduce assembly efficiency, position deviation of projection graphics, etc., and achieve the effect of real-time correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

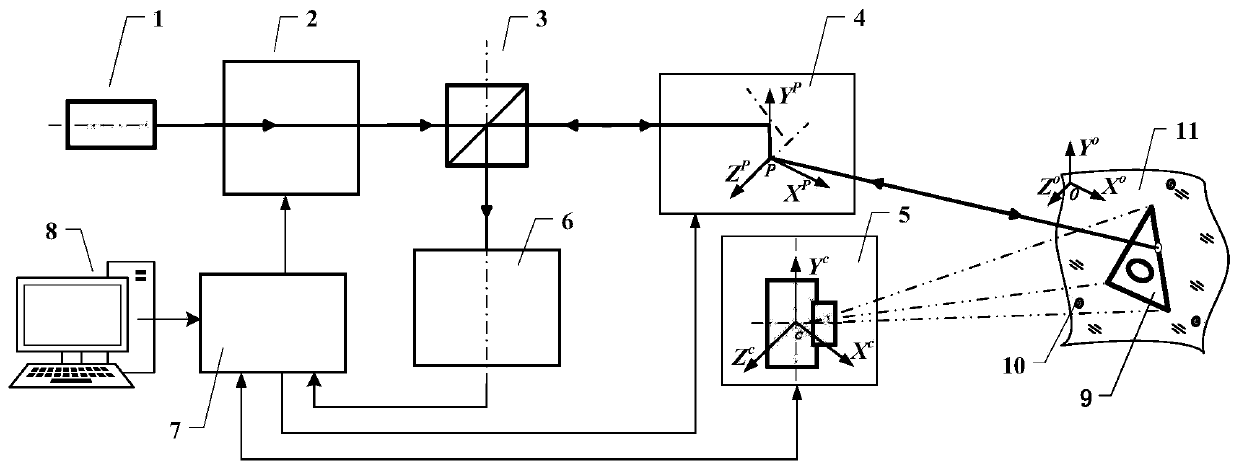

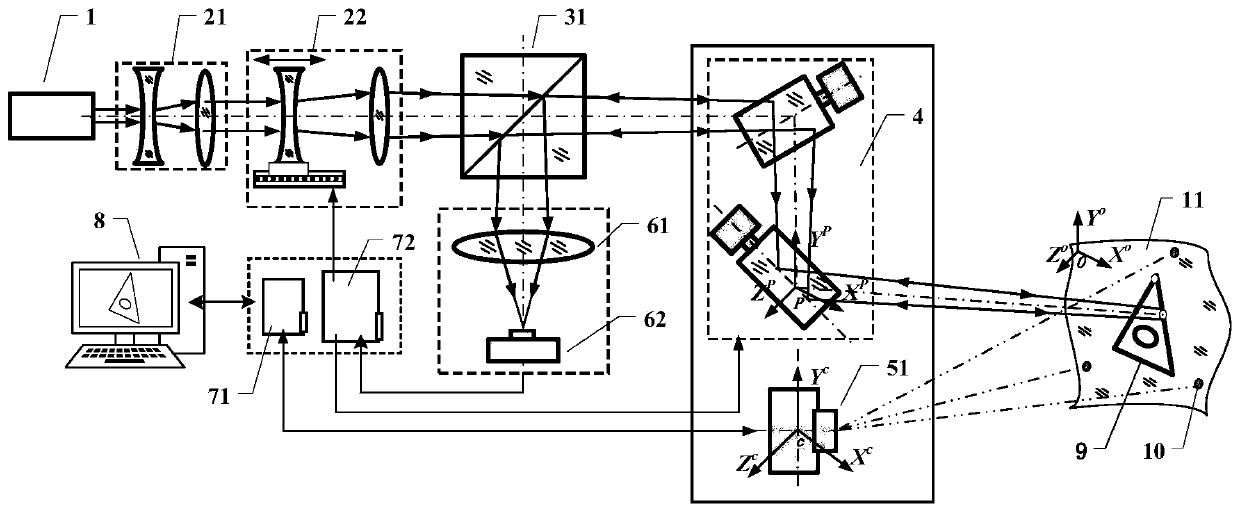

[0079] like image 3 As shown, a novel laser scanning projection device includes: a laser 1, a laser beam expander collimation module 21, an autofocus module 22, a beam splitting prism 31, a two-axis scanning galvanometer module 4, a monocular photogrammetry camera 51, and a light intensity Feedback focusing lens 61, avalanche photodiode detector 62, image acquisition and control board 71, data acquisition and control board 72, host computer controller 8, laser scanning projection graphics 9, back reflection cooperation target 10, projected target Object 11.

[0080] The laser beam emitted by the laser 1 enters the laser beam expansion and collimation module 21 arranged in front of its optical path to complete the collimation and beam expansion of the laser beam, so as to reduce the divergence angle of the laser beam as much as possible. Then it is incident to the auto-focus module 22 arranged in front of the optical path of the laser beam expander and collimator module 21, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com