System and method for reducing noise of tunnel magnetoresistance sensor

A technology of sensor noise and tunnel magnetoresistance, applied in instruments, measuring magnetic variables, measuring devices, etc., can solve problems such as poor noise reduction effect, achieve good noise reduction effect, improve signal-to-noise ratio, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

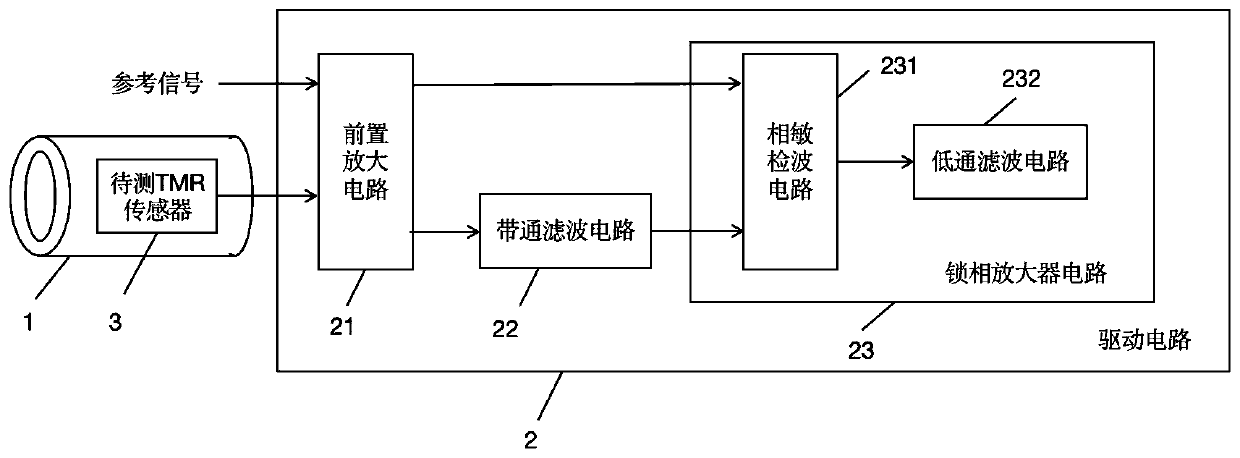

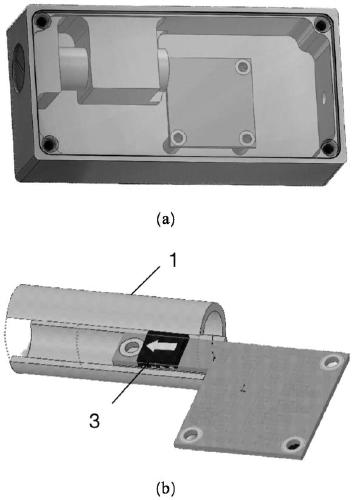

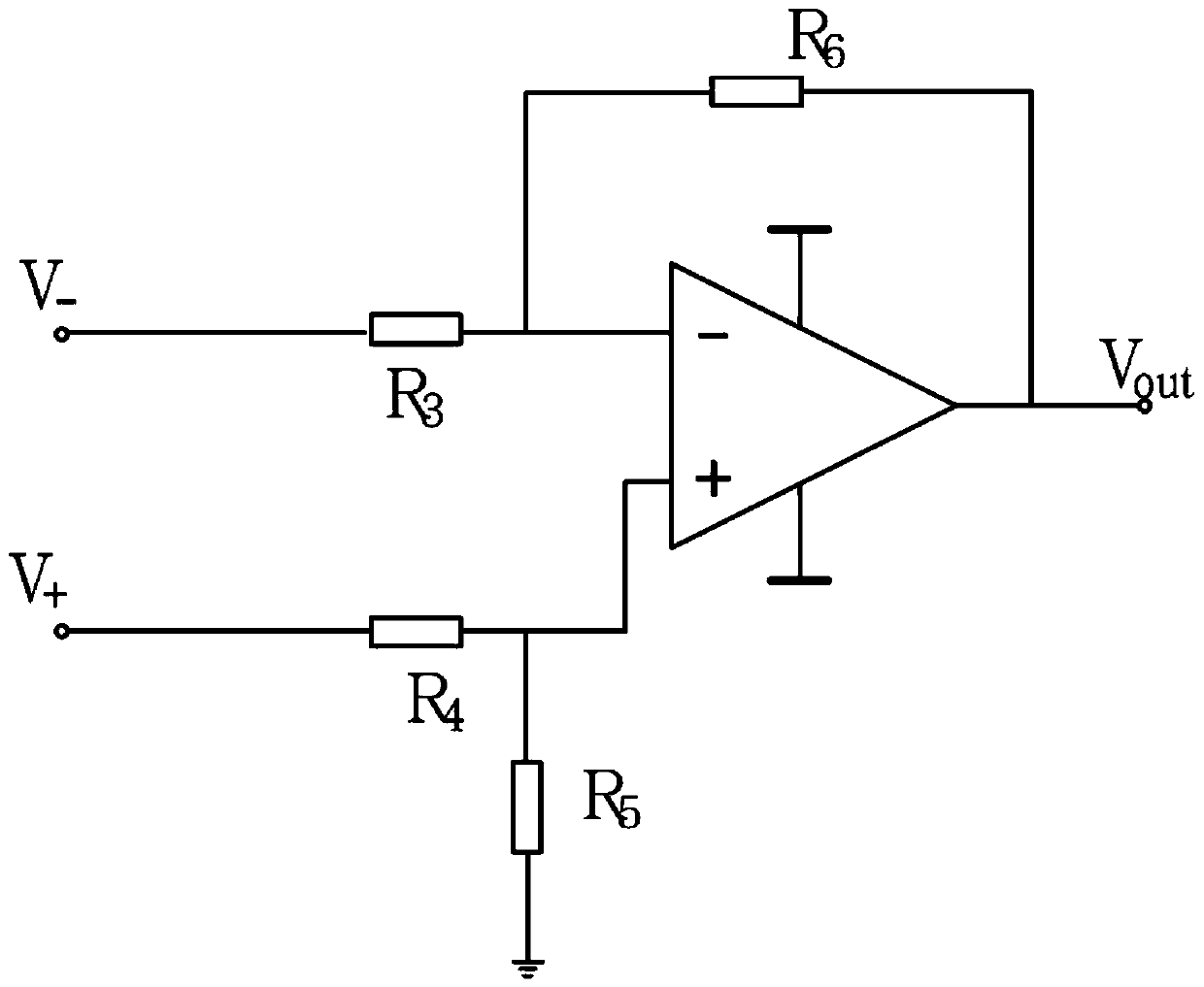

[0036] A system for reducing noise in tunneling magnetoresistive sensors such as figure 1 As shown, it includes: a non-coil shielding cylinder 1 and a drive circuit 2; wherein, the material of the non-coil shielding cylinder 1 is a high permeability soft magnetic material, that is, a soft magnetic material with a relative permeability greater than 5000. In this embodiment, the soft magnetic material with high magnetic permeability is 1J85 type permalloy, and its magnetic permeability will increase and even be saturated under the influence of a weaker magnetic field; , its magnetic permeability will enter the saturation region and decrease with the increase of the induced magnetic field, and the corresponding magnetic shielding ability will also decrease. There are circuit connection points on the non-coil shielding cylinder 1, which can be connected to high-frequency alternating current to realize high-frequency variation of shielding performance, and is wrapped with insulatin...

Embodiment 2

[0042] A method for reducing the noise of a tunnel magnetoresistive sensor, comprising the steps of:

[0043] S1. Place the TMR sensor to be processed in the center of the non-coil shielding cylinder;

[0044] S2. Pass AC current to the non-coil shielding cylinder. Based on the supersaturation characteristics of the high permeability soft magnetic material of the non-coil shielding cylinder, its shielding ability will undergo high-frequency changes, thereby reducing the DC magnetic field to be measured outside the shielding cylinder. Transform into a high-frequency AC magnetic field to reduce the 1 / f noise of the TMR sensor;

[0045] S3. By performing phase-sensitive detection and low-pass filtering on the AC output of the TMR sensor, the sum-frequency signal is filtered out, and the difference-frequency signal is retained, so as to further filter out the 1 / f noise of the TMR sensor.

[0046] Further, the TMR sensor is placed in the center of the non-coil shielding cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com