Wafer manufacturing process flow of high-performance MEMS inertial sensor

A technique for inertial sensors and capping wafers, applied to the photolithography process of the pattern surface, the process for producing decorative surface effects, manufacturing tools, etc., can solve the complex bonding process and the symmetry error of the output of the accelerometer sensor and other problems, to achieve the effect of simple bonding process, high alignment accuracy and good structural symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

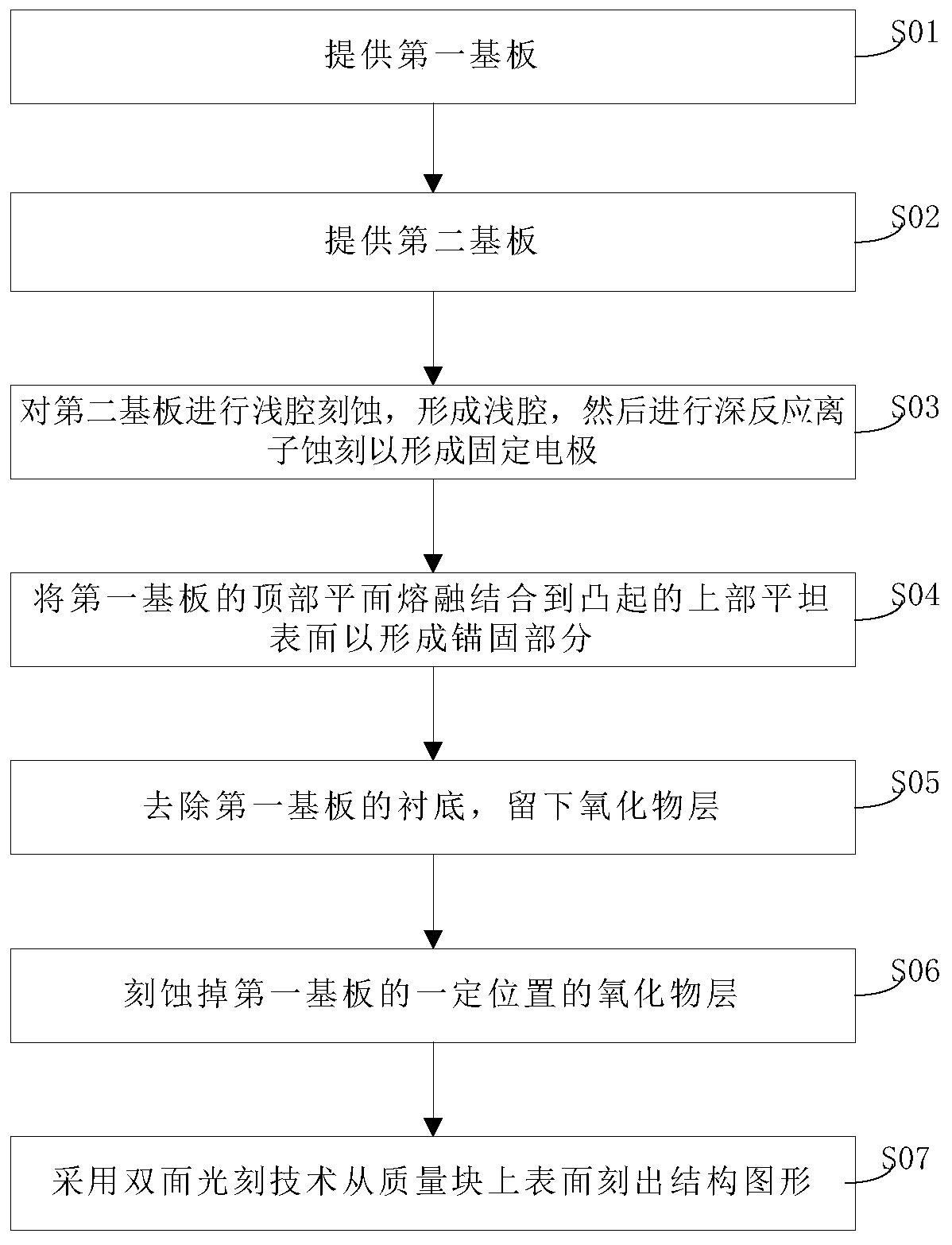

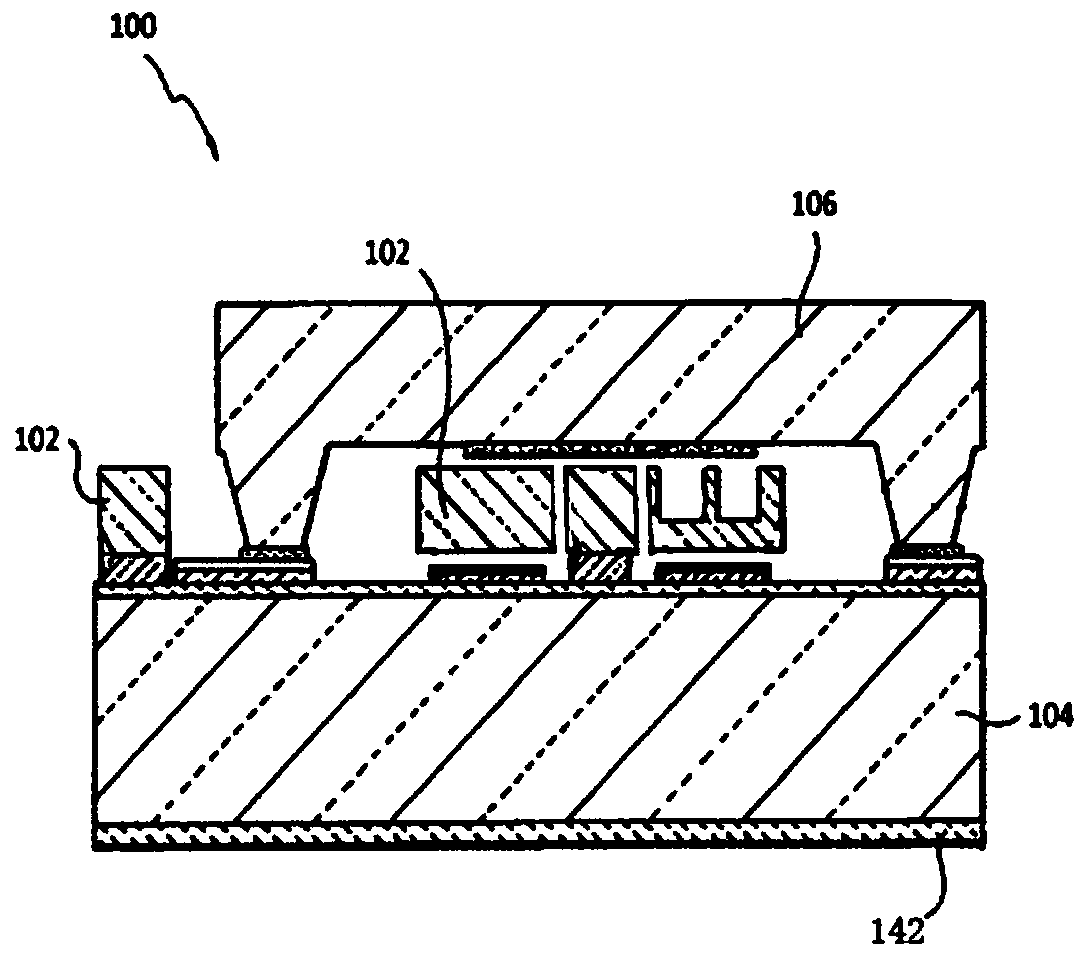

[0052] like figure 1 As shown, the wafer manufacturing process of high-performance MEMS inertial sensors includes the following steps:

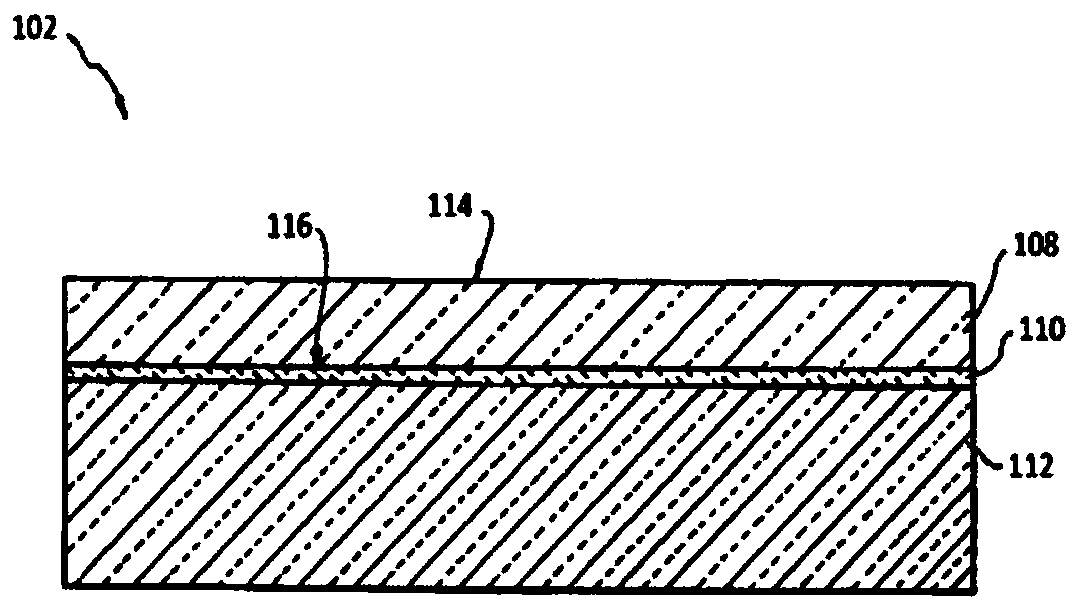

[0053] Providing a first substrate S01: providing a first substrate having a top plane and a bottom plane, an oxide layer is disposed below the bottom plane, and the bottom plane is substantially parallel to the top plane; the first substrate is silicon-on-insulator (SOI) , the top silicon thickness is 50-150μm.

[0054] Providing a second substrate S02: providing a second substrate with an upper flat surface; the second substrate is silicon-on-insulator (SOI), and the silicon thickness is about 5-15 μm.

[0055] Shallow cavity etching S03: Perform photolithographic patterning on the second substrate, perform shallow cavity etching, and etch a part of the second substrate from the upper flat surface to a first predetermined depth (3-10 μm) to form a 3-10 μm A shallow cavity, and a plurality of protrusions, each with an upper flat surface, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com