A control method for weathering steel gear heating

A control method and technology of weathering steel, applied in heat treatment process control, manufacturing tools, heat treatment furnace, etc., can solve the problems of small temperature difference, high price of dual-frequency heating technology power supply, strict heating process requirements, etc., and achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

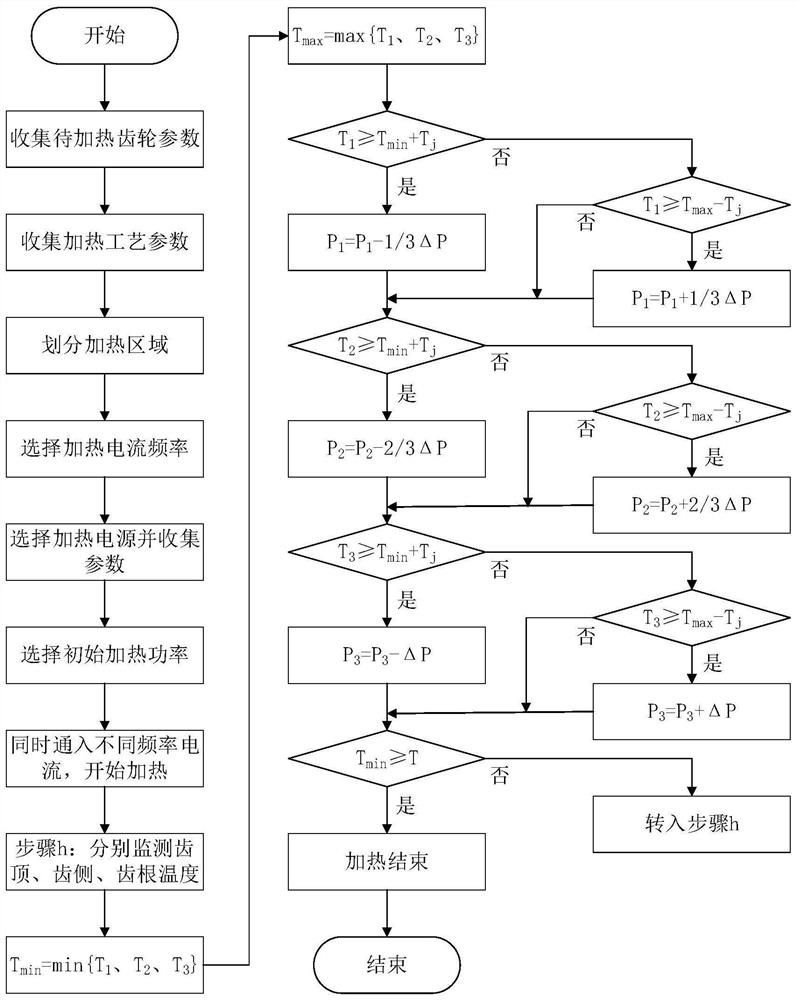

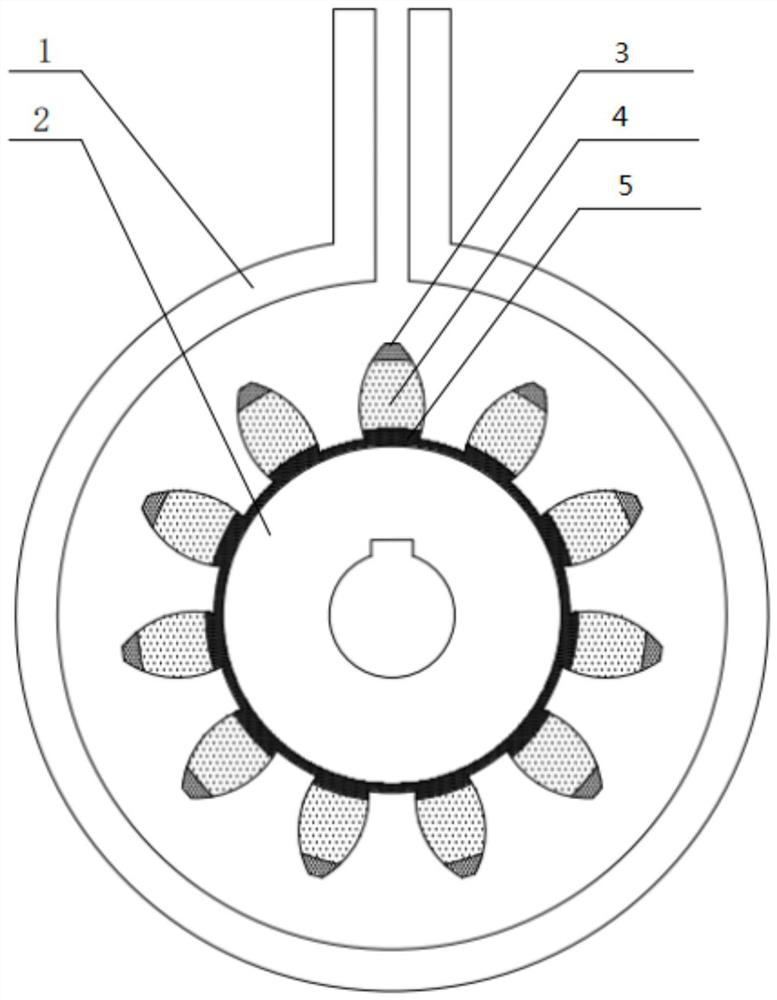

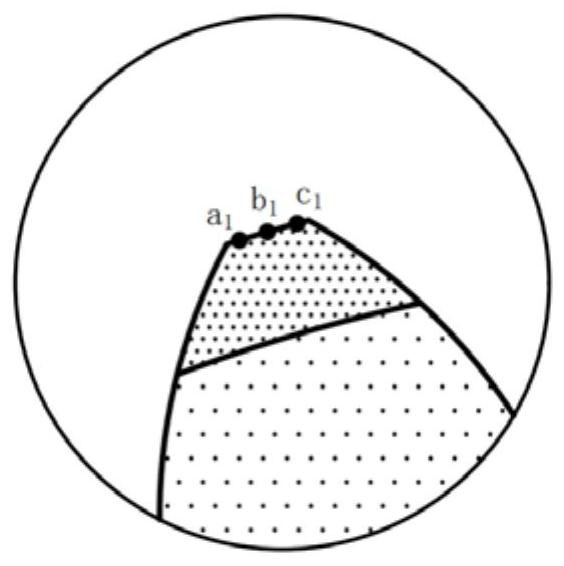

[0043] A control method for heating weather-resistant steel gears. The gear teeth to be heated are divided into three different heating areas, and three single-frequency power supplies are used to simultaneously pass three different frequency currents of high frequency, intermediate frequency, and intermediate frequency to the circular coil. Heating the working parts of the gear to be heated - tooth top, tooth side and tooth root. At the same time, temperature monitoring is carried out on the tooth top, tooth side, and tooth root, and the temperature difference of each part is calculated. Through the temperature difference feedback of each part, the power supply heating power corresponding to each part is adjusted, and the gear to be heated is controlled by gradient heating. The temperature difference is controlled within the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com