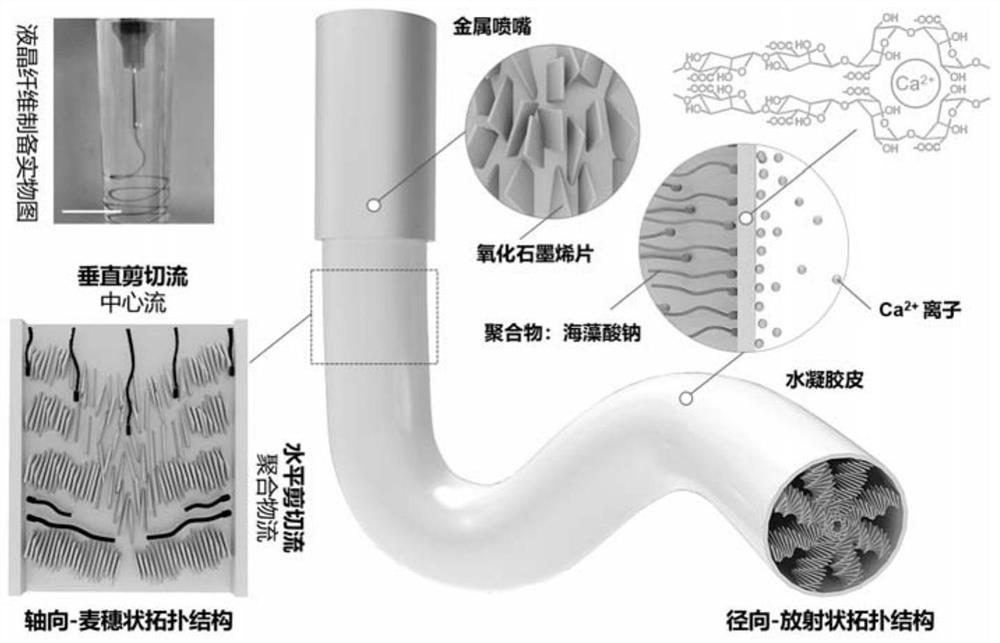

A method for preparing chirality-reversed graphene liquid crystals by nanofluid rectification

A technology of graphene and chirality, which is applied in liquid crystal materials, chemical instruments and methods, wet spinning methods, etc., can solve the problems of inability to realize chirality inversion of liquid crystal arrays, etc., so as to facilitate the promotion and use of industrialization and realize chirality inversion , The effect of simple assembly equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Introduction of polymers that provide radial shear force: 0.05g sodium alginate powder (AR grade, purity 90%, Shanghai Aladdin Biochemical Technology Co., Ltd.) and 0.5g glucose powder (AR grade, Shanghai Aladdin Biochemical Co., Ltd.) Science and Technology Co., Ltd.) was added to 10mL GO (particle size ~ 50μm) solution and magnetically stirred for 10min to prepare a uniform injection, wherein the mass fraction of GO in the GO solution was 0.2wt%;

[0053] 2) Preparation of salt solution to drive the outward migration of the polymer: Add 2.775g of anhydrous calcium chloride (Shanghai Aladdin Biochemical Technology Co., Ltd.) into 500mL of deionized water and sonicate for 5min under 100W ultrasonic conditions to prepare 50mM chlorine Calcium coagulation bath;

[0054] 3) Preparation of chirality-reversed GO liquid crystal fibers

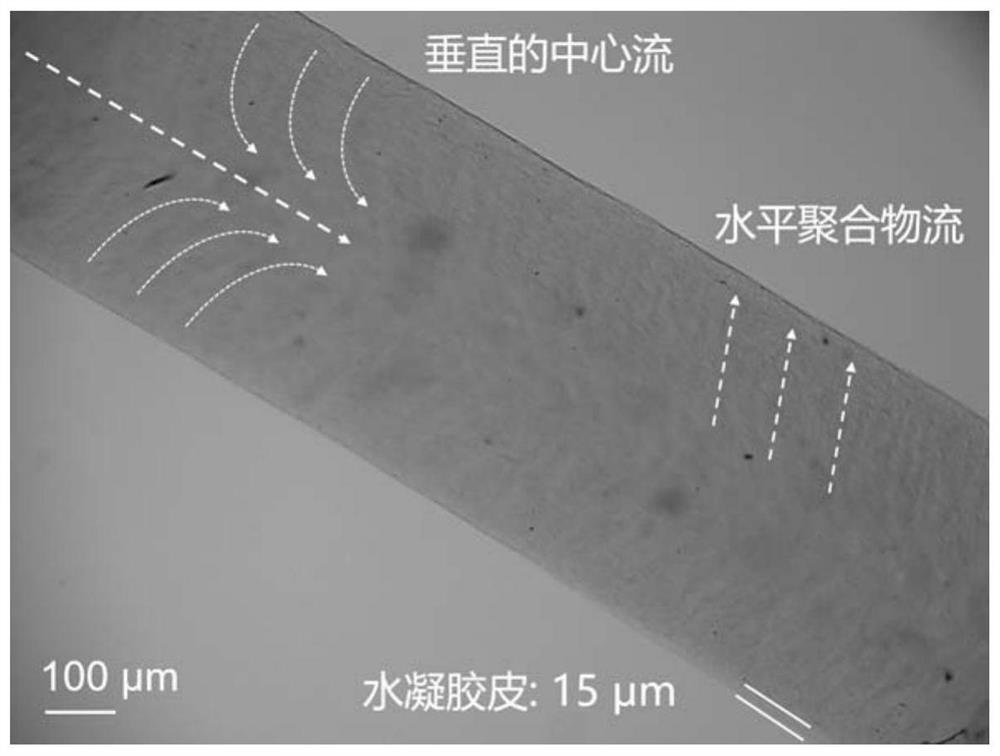

[0055] Inject the receiving liquid obtained in step 1) into the calcium chloride coagulation bath obtained in step 2) through a syringe, ...

Embodiment 2

[0064] Except that the mass fraction of GO in the GO solution in step 1) was changed to a low concentration of 0.08wt% and a high concentration of 0.15wt%, other GO liquid crystal microfibers were prepared according to the same preparation steps as in Example 1.

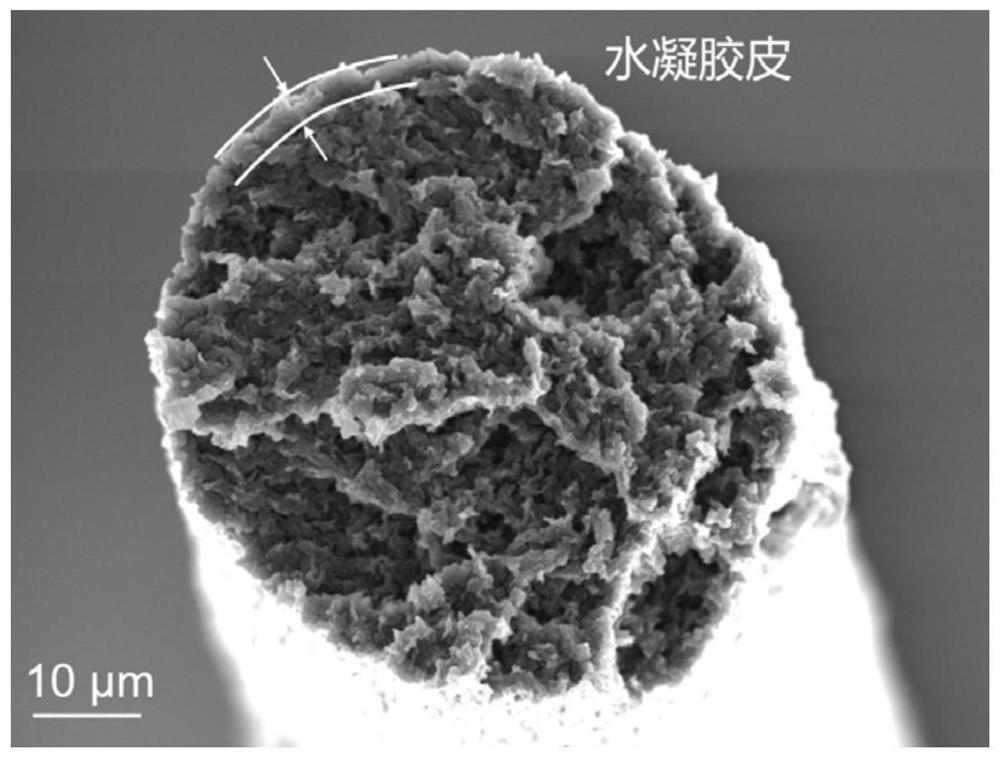

[0065] The radial direction of the GO liquid crystal fiber obtained in Comparative Example 1 is a solid cross pattern, and as the concentration of GO decreases, the cross pattern becomes a hollow cross pattern and a skin-like cross pattern, which is due to the polymer flow driving the GO sheet The layers migrate outward, and the assembly of GO proceeds from the outside in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com