A method of reducing tobacco leaf content

A technology of inclusions and tobacco leaves, applied in the fields of tobacco, processed tobacco, food science, etc., can solve the problems of reducing the content of chemical components in tobacco leaves, and achieve the effects of improving sensory quality, reducing strength, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

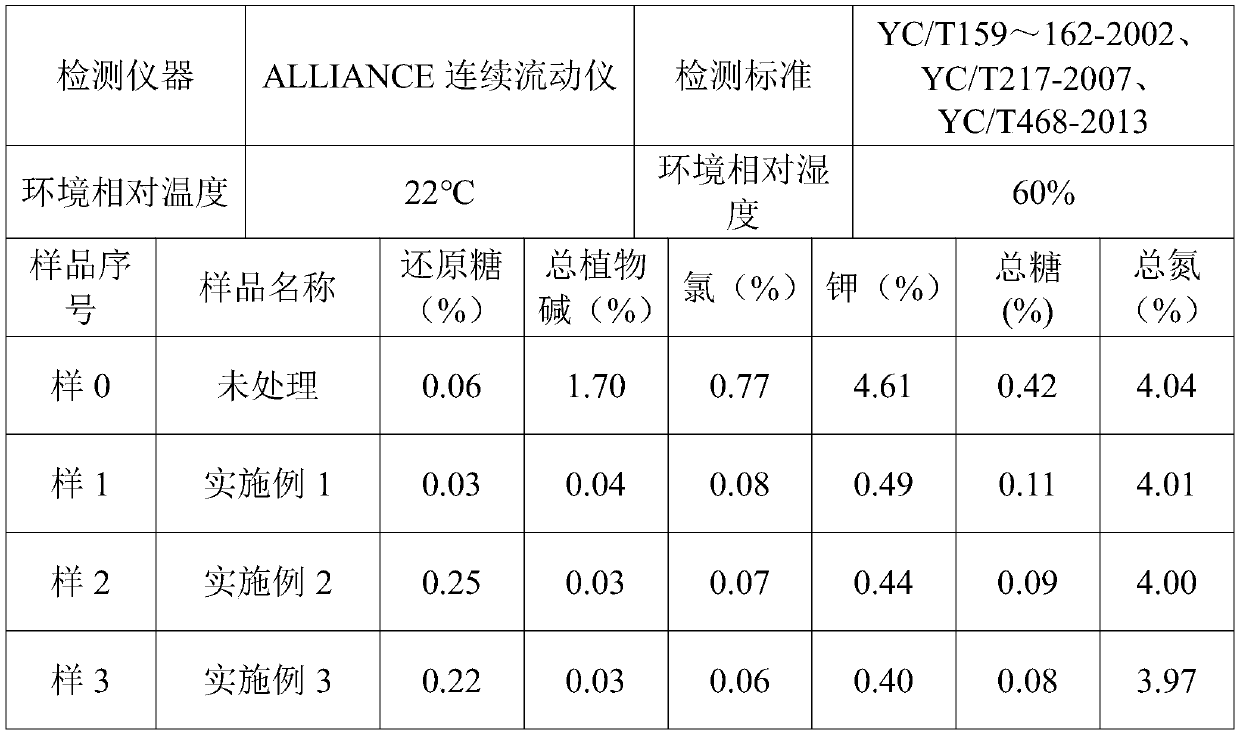

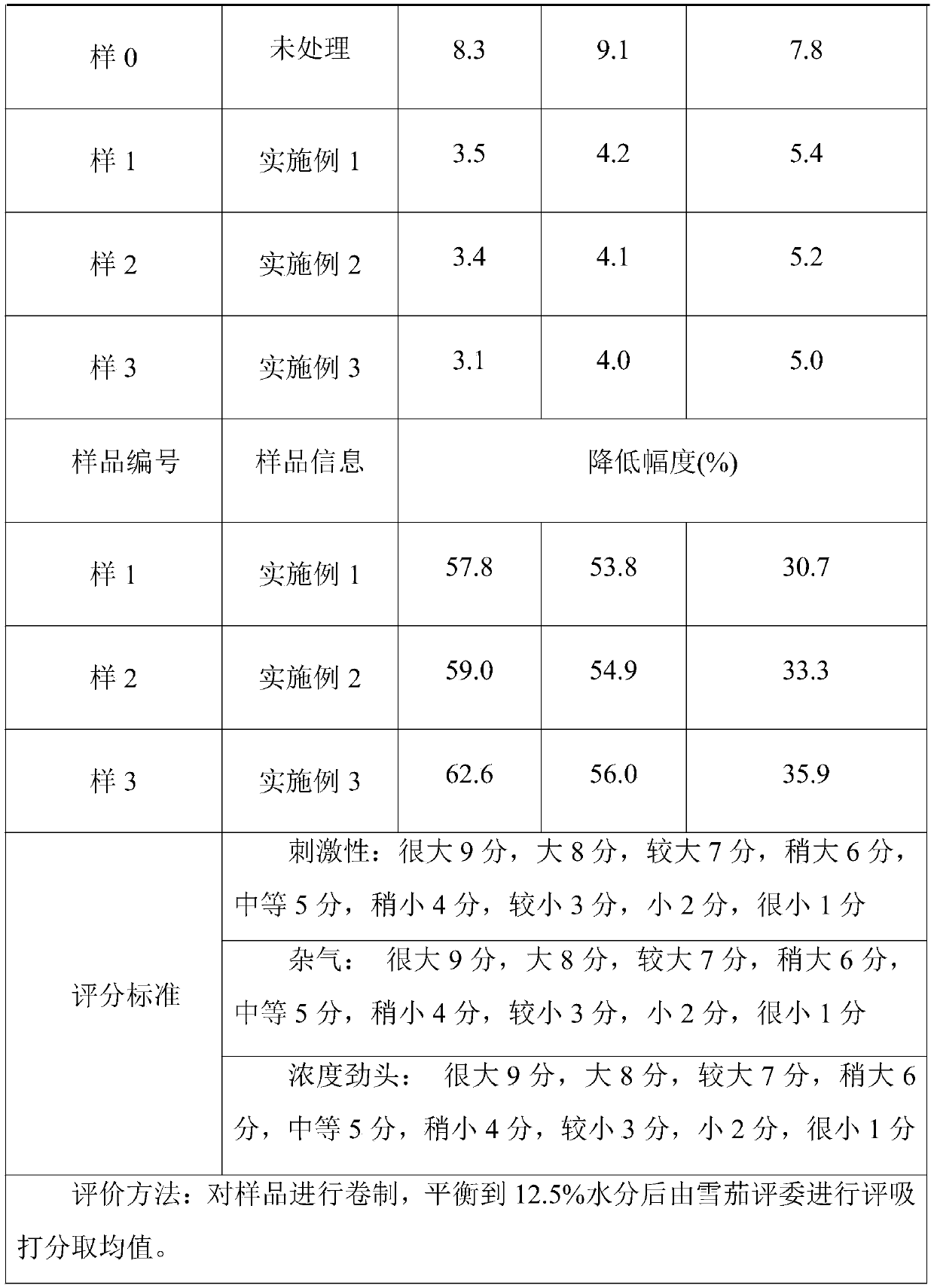

Embodiment 1

[0041] Pack the air-cured tobacco into bags, 5kg per bag, soak and rinse after bagging, the number of soaks is 2 times, and the soaking time is 2 hours each time. The rinse time is 2 hours. After soaking and rinsing, the slices are rinsed within 4 hours. The rinsing time is 20s, the rinsing temperature is 20°C, the rinsing speed is 55Rpm, the rinsing liquid level is 45Cm, and dehydration is carried out after rinsing. The time is 7 minutes, the dehydration speed is 800 Rpm, and after dehydration, it is refrigerated. The refrigerated time is 20 hours, and the refrigerated temperature is 5°C. The temperature is 90°C, and the baking time is 10s. After three times of baking, the smoke sheet is cooled. The temperature in the cooling zone is 45°C, and the cooling time is 5s. The second moisture regain, the temperature of each moisture regain is 80 ℃, and the moisture regain time is 10s. Among them, after the tobacco slices have been baked for 3 times, the time to complete the moistu...

Embodiment 2

[0043]Pack the air-cured tobacco into bags, 5kg per bag, soak and rinse after bagging, the number of soaks is 4 times, and the soaking time is 1 hour each time. The rinse time is 1 hour. After soaking and rinsing, the slices are rinsed within 4 hours. The rinsing time is 40 seconds, the rinsing temperature is 30°C, the rinsing speed is 75 Rpm, the rinsing liquid level is 60 cm, and dehydration is performed after rinsing. The time is 8 minutes, the dehydration speed is 1000 Rpm, and after dehydration, it is refrigerated. The refrigerated time is 10 hours, and the refrigerated temperature is 5°C. The temperature is 110°C, and the baking time is 13s. After three times of baking, the smoke sheet is cooled. The temperature in the cooling zone is 45°C, and the cooling time is 8s. The temperature of each resurgence is 75°C, and the resurgence time is 12s. Among them, after the tobacco slices have been baked for 3 times, the time to complete the moisture regaining treatment twice in ...

Embodiment 3

[0045] Pack the air-dried tobacco into bags, 5kg per bag, soak and rinse after bagging, the number of soaks is 3 times, and the soaking time is 1 hour each time. The rinse time is 1 hour. After soaking and rinsing, the tobacco slices are rinsed within 4 hours. The rinsing time is 30 seconds, the rinsing temperature is 23°C, the rinsing speed is 55 Rpm, and the rinsing liquid level is 55 Cm. After rinsing, dehydrate. The time is 5 minutes, the dehydration speed is 900 Rpm, and after dehydration, it is refrigerated. The refrigerated time is 5 hours, and the refrigerated temperature is 5°C. The temperature is 100°C, and the baking time is 15s. After three times of baking, the smoke sheet is cooled. The temperature in the cooling zone is 40°C, and the cooling time is 10s. The second moisture regain, the temperature of each moisture regain is 75 ℃, and the moisture regain time is 15s. Among them, after the tobacco slices have been baked for 3 times, the time to complete the moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com