LPG normal-temperature dry desulfurization purification process

A dry desulfurization and purification process technology, which is applied in the petroleum industry, gas mixture processing, and hydrocarbon oil treatment. It can solve the problems of unsuitability for small and medium-sized refineries, complex processes, increased production and investment costs, and achieve investment and operation. Low cost, simple process flow, and the effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

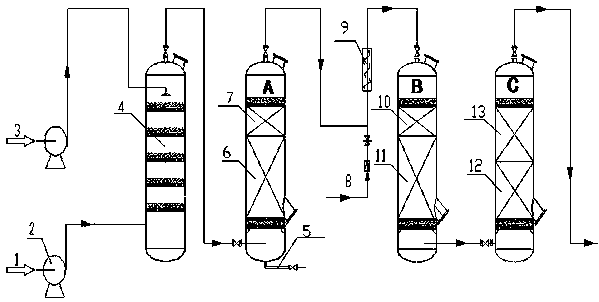

[0031] A refinery LPG contains about 50mg / m 3 H 2 S, 10mg / Nm 3 RSH, 1-2mg / Nm 3 HCOOH, 1-2mg / Nm 3 CH 3 OH, the raw material LPG1 enters the water washing tower 4 from bottom to top after being metered and pressurized by the feed pump 2, and the countercurrent in the water washing tower 4 contacts with the washing water 3 added with 50ppm of hydroxyethyl hexahydro-s-triazine to remove it. Contains HCOOH, CH 3OH, HCHO, DME and other aldols and ethers enter the reactor A from bottom to top. The bottom of reactor A is equipped with a shower 5 to regularly discharge the water brought by the washing device. In terms of volume ratio, the lower 2 / 3 bed of reactor A is equipped with Fe-Ca-based desulfurizer 6, and the upper 1 / 3 bed is equipped with Ni-Ca-based desulfurizer 7. Fe, Ni, and Ca in the desulfurizer are respectively With γ-FeOOH, NiCO 3 2Ni(OH) 2 4H 2 O, Nano-CaCO 3 form exists. H in LPG after purified by A reactor 2 S, Cl, F are all less than 1mg / Nm 3 , the LPG...

Embodiment 2

[0033] A refinery LPG contains about 50mg / m 3 H 2 S, 10mg / Nm 3 RSH, 1-2mg / Nm 3 HCOOH, 1-2mg / Nm 3 CH 3 OH, the raw material LPG1 enters the water washing tower 4 from bottom to top after being metered and pressurized by the feed pump 2, and the countercurrent in the water washing tower 4 contacts with the washing water 3 added with 300ppm of hydroxyethyl hexahydro-s-triazine to remove it. Contains HCOOH, CH 3 OH, HCHO, DME and other aldols and ethers enter the reactor A from bottom to top. The bottom of reactor A is equipped with a shower 5 to regularly discharge the water brought by the washing device. In terms of volume ratio, the lower 2 / 3 bed of reactor A is equipped with Fe-Ca-based desulfurizer 6, and the upper 1 / 3 bed is equipped with Ni-Ca-based desulfurizer 7. Fe, Ni, and Ca in the desulfurizer are respectively With γ-FeOOH, NiCO 3 2Ni(OH) 2 4H 2 O, Nano-CaCO 3 form exists. H in LPG after purified by A reactor 2 S, Cl, F are all less than 1mg / Nm 3 , the LP...

Embodiment 3

[0035] A refinery LPG contains about 50mg / m 3 H 2 S, 10mg / Nm 3 RSH, 1-2mg / Nm 3 HCOOH, 1-2mg / Nm 3 CH 3 OH, the raw material LPG1 enters the water washing tower 4 from bottom to top after being metered and pressurized by the feed pump 2, and the countercurrent in the water washing tower 4 contacts with the washing water 3 added with 500ppm of hydroxyethyl hexahydro-s-triazine, and removes it. Contains HCOOH, CH 3 OH, HCHO, DME and other aldols and ethers enter the reactor A from bottom to top. The bottom of reactor A is equipped with a shower 5 to regularly discharge the water brought by the washing device. In terms of volume ratio, the lower 2 / 3 bed of reactor A is equipped with Fe-Ca-based desulfurizer 6, and the upper 1 / 3 bed is equipped with Ni-Ca-based desulfurizer 7. Fe, Ni, and Ca in the desulfurizer are respectively With γ-FeOOH, NiCO 3 2Ni(OH) 2 4H 2 O, Nano-CaCO 3 form exists. H in LPG after purified by A reactor 2 S, Cl, F are all less than 1mg / Nm 3 , the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap