Waterproof, moisture-proof, high-toughness and anti-cracking pavement joint strip

A technology of seam tape and performance, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of insufficient crack resistance and anti-slip performance of the seam tape, and achieve excellent waterproof layer and high tensile strength. , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

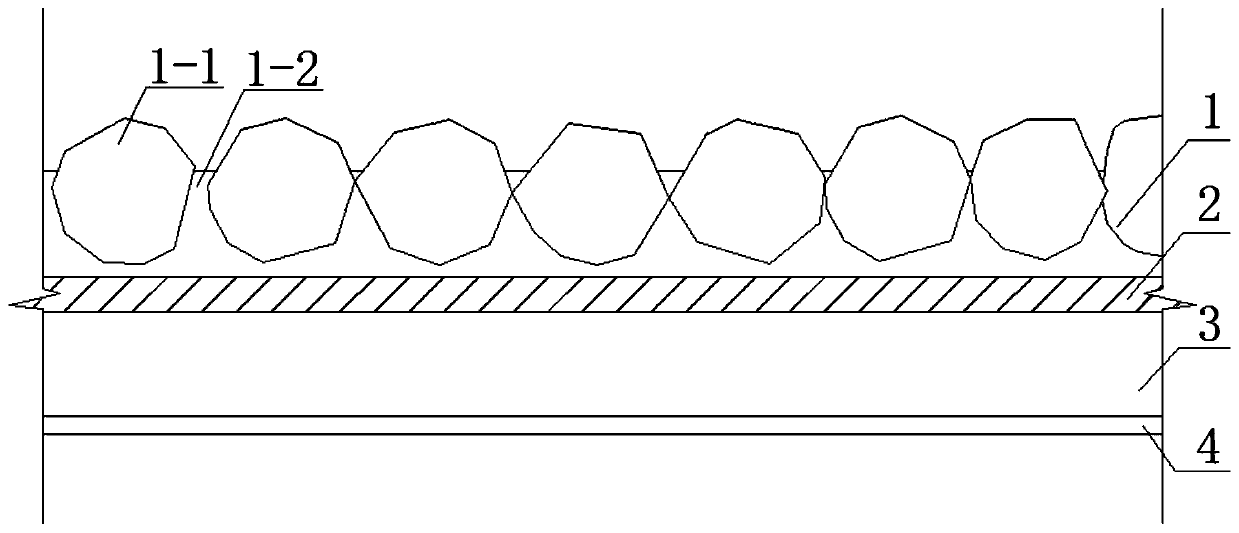

[0025] Such as figure 1 As shown, a pavement seam tape with waterproof, anti-slip, high toughness and anti-crack performance, which consists of an anti-slip wear layer 1; a fiber anti-crack layer 2; an asphalt adhesive layer 3; an anti-adhesive film layer 4 Composition; the anti-skid wear layer 1 is epoxy asphalt gravel, the epoxy asphalt component is 100 parts of asphalt, 40 parts of epoxy resin, and the gravel is diabase gravel of 1.0-3.0 mm; the fiber is crack-resistant Layer 2 is 300g / m 2 Basalt fiber bidirectional cloth; the asphalt bonding layer 3 is high-fraction polymerization modified asphalt, its dynamic viscosity at 60°C is greater than 20,000MPa, its dynamic viscosity at 135°C is less than 4.5MPa, and its softening point is greater than 80°C; the anti-adhesive film layer 4 is A polyethylene film coated with an anti-sticking coating on both sides; the preparation method of the seam tape is: (1) heating the basalt fiber cloth to 150°C; (2) preparation of the anti-sl...

Embodiment 2

[0029] Such as figure 1 As shown, a pavement seam tape with waterproof, anti-slip, high toughness and anti-crack performance, which consists of an anti-slip wear layer 1; a fiber anti-crack layer 2; an asphalt adhesive layer 3; an anti-adhesive film layer 4 Composition; the anti-skid wear layer 1 is epoxy asphalt macadam, the epoxy asphalt component is 100 parts of asphalt, 60 parts of epoxy resin, and the macadam is 3.0-5.0mm diabase macadam; the fiber crack resistance Layer 2 is 300g / m 2 Basalt fiber bidirectional cloth; the asphalt bonding layer 3 is high-fraction polymerization modified asphalt, its dynamic viscosity at 60°C is greater than 20,000MPa, its dynamic viscosity at 135°C is less than 4.5MPa, and its softening point is greater than 80°C; the anti-adhesive film layer 4 is A polyethylene film coated with an anti-sticking coating on both sides; the preparation method of the seam tape is: (1) heating the basalt fiber cloth to 150°C; (2) preparation of the anti-slip ...

Embodiment 3

[0031] Such as figure 1 As shown, a pavement seam tape with waterproof, anti-slip, high toughness and anti-crack performance, which consists of an anti-slip wear layer 1; a fiber anti-crack layer 2; an asphalt adhesive layer 3; an anti-adhesive film layer 4 Composition; the anti-skid wear layer 1 is asphalt gravel, the asphalt is high-fraction polymerized asphalt, and the gravel is 1.0-5.0mm diabase gravel; the fiber anti-cracking layer 2 is 300g / m 2 Basalt fiber bidirectional cloth; the asphalt bonding layer 3 is high-fraction polymerization modified asphalt, its dynamic viscosity at 60°C is greater than 20,000MPa, its dynamic viscosity at 135°C is less than 4.5MPa, and its softening point is greater than 80°C; the anti-adhesive film layer 4 is A polyethylene film coated with an anti-stick coating on both sides; the preparation method of the seam tape is: (1) heating the basalt fiber cloth to 150°C; (2) preparation of the anti-slip wear layer: spraying asphalt on the upper la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com