Lithium ion battery structure and lithium supplementing method

A lithium-ion battery, lithium-ion technology, applied in secondary batteries, battery electrodes, structural parts, etc., can solve problems such as poor practicability, increased film volume for diaphragms, and increased impedance, achieving good compatibility and high efficiency. , to avoid the effect of heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

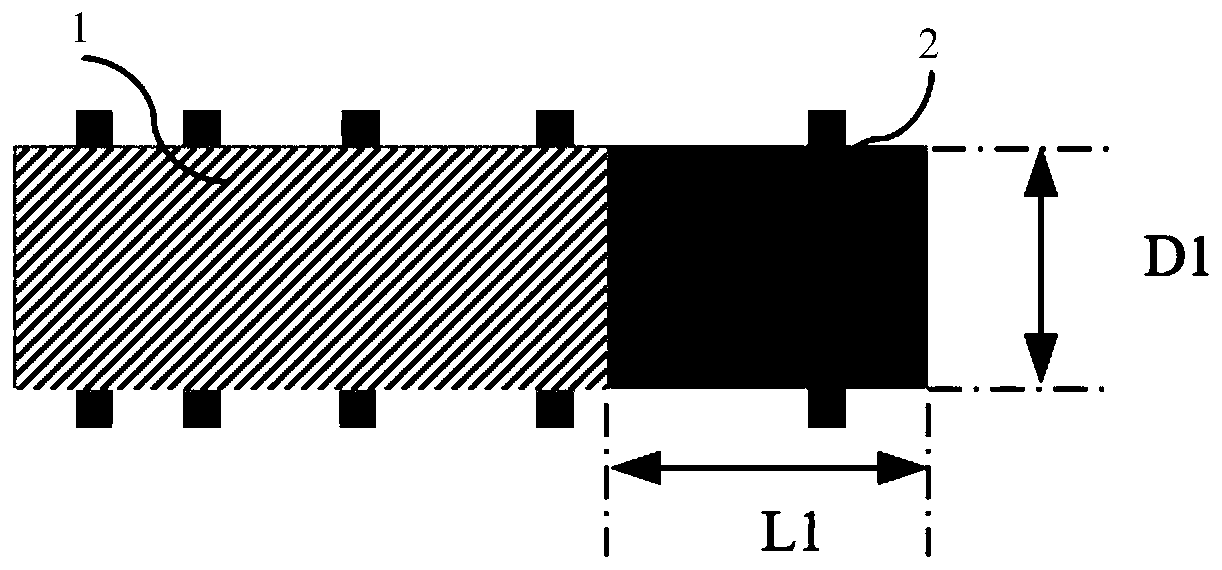

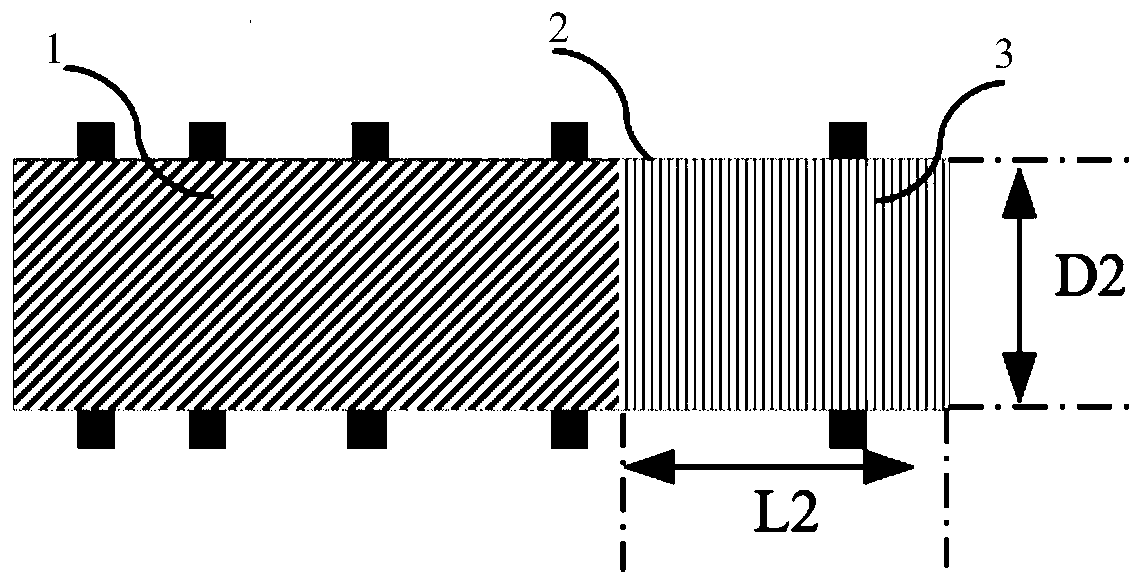

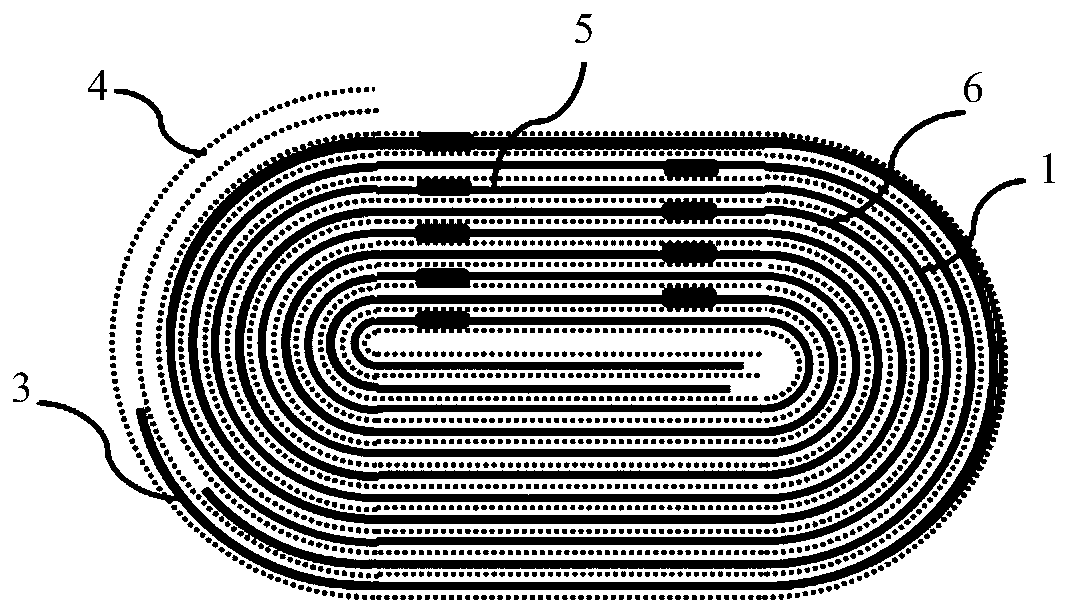

[0037] The negative electrode sheet 5 in the present embodiment is to use Si / C as the negative electrode active material, dissolves in water according to the ratio of 96.2% negative electrode active material, 1.0% conductive carbon black, 1.0% CMC, 1.8% SBR (the ratio is based on the negative electrode sheet mass), prepared into a uniform and air-free slurry, and the front side of the negative pole piece 5 according to figure 1 The blank area 2 of the current collector is pre-coated on the copper foil current collector with a porosity of 0% to form the coating area 1 and the blank area 2 of the current collector. The length of the blank area 2 of the current collector is roll The length L1 of the outermost turn of the winding core after winding is equal to the width D1 of the negative pole piece 5 . Then, it is dried and rolled to prepare the negative electrode sheet 5 .

[0038] Lithium supplementation will be carried out according to 8% of the design capacity of the battery...

Embodiment 2

[0043] The negative electrode sheet 5 in the present embodiment is to use Si / C as the negative electrode active material, dissolves in water according to the ratio of 96.2% negative electrode active material, 1.0% conductive carbon black, 1.0% CMC, 1.8% SBR (the ratio is based on the negative electrode sheet mass), prepared into a uniform and air-free slurry, and the front side of the negative pole piece 5 according to figure 1 The blank area 2 of the current collector is pre-coated on the copper foil current collector with a porosity of 5% to form the coating area 1 and the blank area 2 of the current collector. The length of the blank area 2 of the current collector is The length L1 of the outermost turn of the winding core after winding is equal to the width D1 of the negative pole piece 5 . Then, it is dried and rolled to prepare the negative electrode sheet 5 .

[0044] Lithium supplementation will be carried out according to 15% of the designed capacity of the battery c...

Embodiment 3

[0049] The negative electrode sheet 5 in the present embodiment uses graphite as the negative electrode active material, which is dissolved in water according to the ratio of 96.2% negative electrode active material, 1.0% conductive carbon black, 1.0% CMC, and 1.8% SBR (the ratio is based on the quality of the negative electrode sheet) , prepared into a uniform and air-free slurry, the front of the negative pole piece 5 is according to figure 1 The blank area 2 of the current collector is pre-coated on the copper foil current collector with a porosity of 0% to form the coating area 1 and the blank area 2 of the current collector. The length of the blank area 2 of the current collector is roll The length L1 of the outermost turn of the winding core after winding is equal to the width D1 of the negative pole piece 5 . Then it is dried and rolled to prepare a negative electrode sheet.

[0050] Lithium supplementation will be carried out according to 8% of the designed capacity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com