Asymmetrical phase-adjustable Mach-Zehnder interferometer and preparation method thereof

An interferometer and asymmetric technology, applied in the coupling of optical waveguides, etc., can solve the problems of optical path difference between the two arms, optical sensing, communication system reconfiguration, constant output characteristics, etc., and achieve low cost, Overcoming the instability problem, the effect of finely adjustable phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned asymmetric phase-tunable Mach-Zehnder interferometer comprises the following steps:

[0042] Step 10): Take a silicon substrate, and clean the silicon wafer by wet chemical method. A silicon dioxide buffer layer with a thickness of 15 μm to 20 μm is prepared on the silicon substrate by a thermal oxidation method. Using the plasma-enhanced chemical vapor deposition method, the concentration of silane and nitrogen was 5% S i h 4 :N 2 , the temperature is 250°C-400°C, silicon dioxide is doped with germanium dioxide to obtain a waveguide layer 9 with a thickness of 8 μm, and GeH with a gas concentration of 10% is used 4 : Ar, form a waveguide layer with a thickness of 8 μm, and the difference between the refractive index of the waveguide layer and the refractive index of the silica buffer layer is 0.4%.

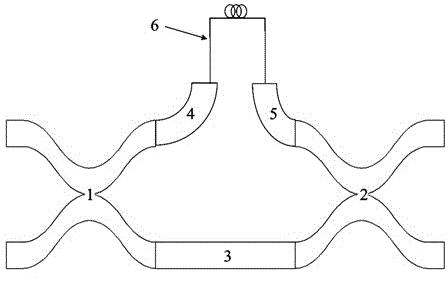

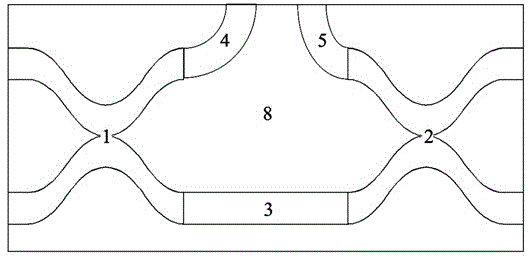

[0043] Step 20): On the waveguide layer, use photolithography and etching processes to prepare the PLC chip part of the a...

Embodiment

[0051] The preparation method of the asymmetric phase-tunable Mach-Zehnder interferometer is introduced below, so as to describe the above preparation method in more detail.

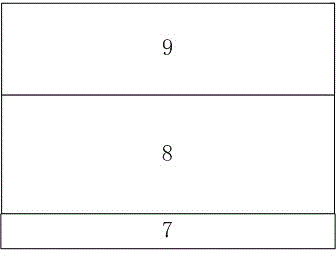

[0052] Step 10): making the silicon dioxide buffer layer 8 and the waveguide 9 . refer to figure 2 As shown, it includes step 101), step 102) and step 103).

[0053] Step 101) Take a silicon substrate, clean the silicon wafer, that is, the substrate 7, by wet chemical method, and remove the dirt on the surface; then, after ultrasonic cleaning and drying with deionized water, the cleaning of the silicon wafer is completed;

[0054] Step 102) Prepare the silica buffer layer 8. There are many methods for preparing the silica buffer layer 8, such as chemical vapor deposition (CVD), flame hydrolysis (FHD), sol-gel method (Sol-Gel), Thermal oxidation (TO), etc. Since the thermal oxidation method can oxidize hundreds of silicon wafers at the same time, it has higher efficiency in actual production, and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com