High-flux plasma discharge device and hydrogen sulfide decomposition method

A plasma and discharge device technology, applied in the field of plasma chemistry, can solve the problems of low hydrogen sulfide conversion rate, high energy consumption, and inability to realize large flow rate, and achieve the goal of improving conversion rate, high conversion rate, and stable long-term operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

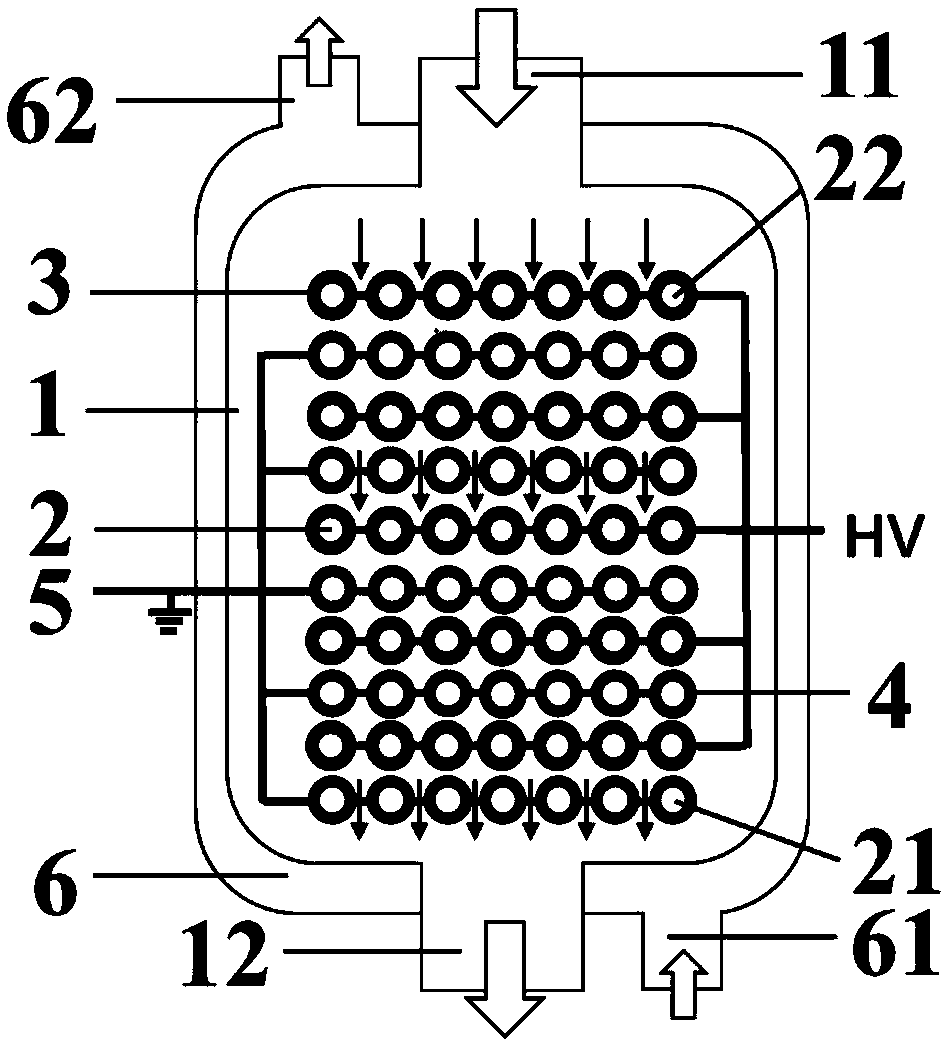

[0126] use figure 1 The shown device carries out hydrogen sulfide decomposition reaction, and the specific structure and structural parameters of the low-temperature plasma discharge device are as follows:

[0127] Devices include:

[0128] a first cavity, the first cavity is respectively provided with a first inlet and a first outlet;

[0129] A high-voltage electrode, the high-voltage electrode is arranged in the first cavity, and the high-voltage electrode is provided with 5 layers in the first cavity; in each layer structure containing the high-voltage electrode, the high-voltage electrode The number is 7, each of the high-voltage electrodes is parallel to each other, and there is a gap between two adjacent high-voltage electrodes, the material forming the high-voltage electrodes is a hollow stainless steel metal tube, and the size of each of the high-voltage electrodes is the same ;

[0130] A ground electrode, the ground electrode is arranged in the first cavity, and ...

Embodiment 2

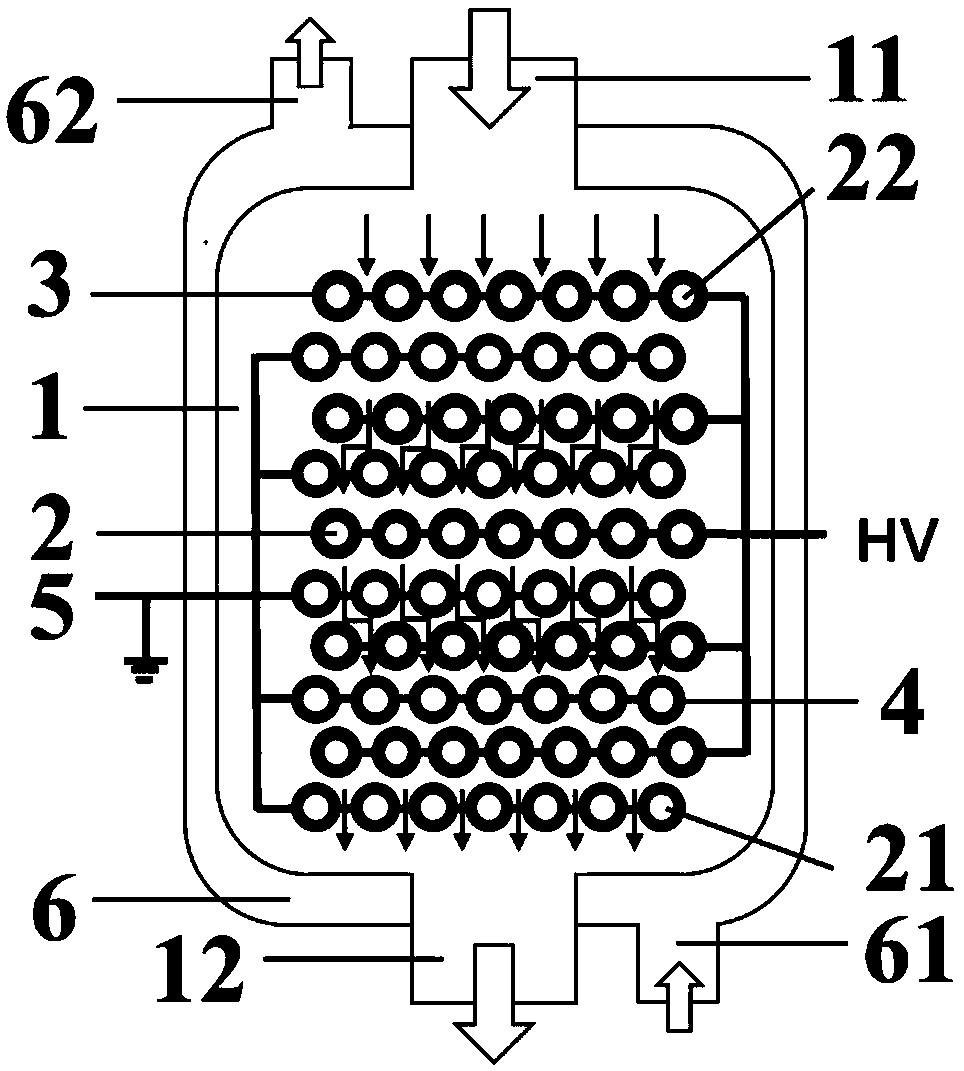

[0144] This embodiment adopts figure 2 The shown device carries out hydrogen sulfide decomposition reaction, and the specific structure and structural parameters of the discharge device are as follows:

[0145] Devices include:

[0146] a first cavity, the first cavity is respectively provided with a first inlet and a first outlet;

[0147] A high-voltage electrode, the high-voltage electrode is arranged in the first cavity, and the high-voltage electrode is provided with 5 layers in the first cavity; in each layer structure containing the high-voltage electrode, the high-voltage electrode The number is 7, each of the high-voltage electrodes is parallel to each other, and there is a gap between two adjacent high-voltage electrodes, the material forming the high-voltage electrodes is a hollow graphite tube, and the size of each of the high-voltage electrodes is the same;

[0148] A ground electrode, the ground electrode is arranged in the first cavity, and the ground electro...

Embodiment 3

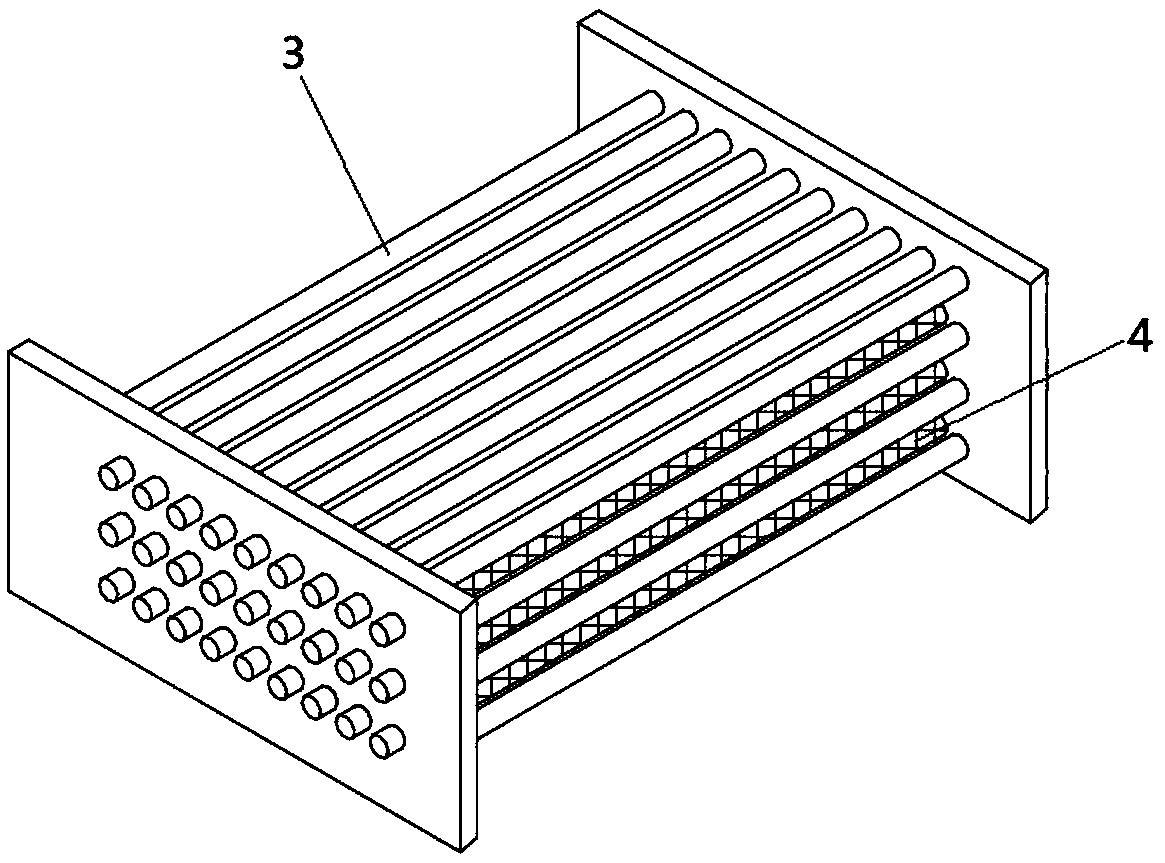

[0162] This embodiment is carried out using a discharge device similar to that of Embodiment 1. The difference is that the barrier medium in the discharge device of this embodiment is arranged on the outer surface of the high-voltage electrode and the ground electrode, that is, a double dielectric barrier discharge.

[0163] And the gap between two adjacent high-voltage electrodes and two adjacent ground electrodes is equal, and the gap between two adjacent layer structures is 1.2 times the gap between two adjacent high-voltage electrodes, L 2 The ratio to the thickness D1 of the barrier medium is 15:1;

[0164] The size of each of the high-voltage electrodes is the same as that of each of the ground electrodes, and the ratio of diameter to length is 1:130;

[0165] L 2 and the length of the discharge tube L3 The ratio between them is 1:300;

[0166] The volume of the first cavity of the low-temperature plasma discharge device of this embodiment is 3.2L.

[0167] Pass H in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com