High-throughput low-temperature plasma system for decomposing hydrogen sulfide and method for decomposing hydrogen sulfide

A low-temperature plasma and plasma technology, which is applied in the field of ion chemistry, can solve the problems of low hydrogen sulfide conversion rate and high decomposition energy consumption, and achieve the effects of long-term operation, flexible temperature control, high continuity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

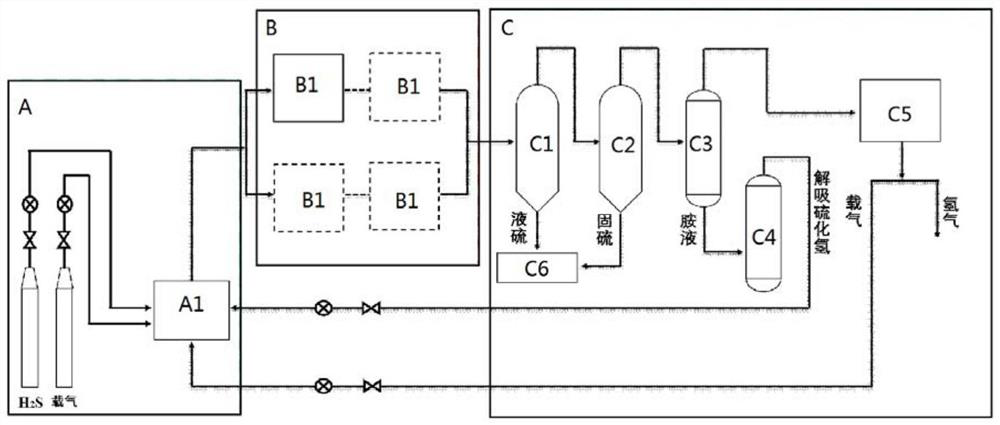

[0093]Nitrogen gas is passed from the reactor inlet to the inner cylinder of the high-flux plasma reaction device to remove the air in the discharge area, and the gas is drawn out from the product outlet. At the same time, the heat transfer medium is introduced into the outer cylinder from the heat transfer medium inlet, and the introduced heat transfer medium is led out from the heat transfer medium outlet. The temperature of the heat transfer medium is maintained at the temperature required by the system reaction. Then feed raw material gas containing hydrogen sulfide from the reactor inlet to the inner cylinder of the high-throughput plasma reaction device. The raw material gas fills each reaction tube. A plasma discharge field is formed between the high voltage electrode and the ground electrode. The hydrogen sulfide gas is ionized in the discharge area and decomposed into hydrogen and elemental sulfur. The elemental sulfur produced by the discharge slowly flows down the ...

Embodiment 1

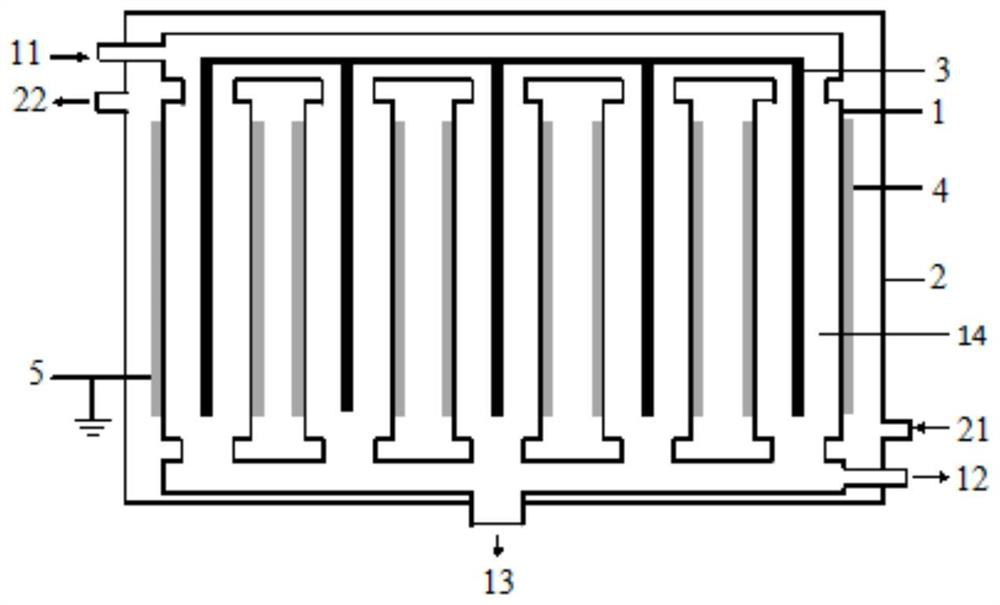

[0147] use has image 3 The high-throughput low-temperature plasma system for decomposing hydrogen sulfide in the flow chart shown in the flow chart performs the hydrogen sulfide decomposition reaction, and the low-temperature plasma reactor in this embodiment has figure 1 structure shown.

[0148] The process flow of this embodiment is as shown in the aforementioned specific implementation, and the structural parameters of the low-temperature plasma reactor are as follows:

[0149] Low temperature plasma reactors include:

[0150] An inner cylinder, the inner cylinder is respectively provided with a reactor inlet, a gas product outlet and a liquid product outlet, and the inner cylinder contains 4 reaction tubes arranged side by side, and the top and bottom of each of the reaction tubes communicate with each other correspondingly, The raw materials that enter from the inlet of the reactor can enter into each of the reaction tubes respectively, and the gaseous products produc...

Embodiment 2

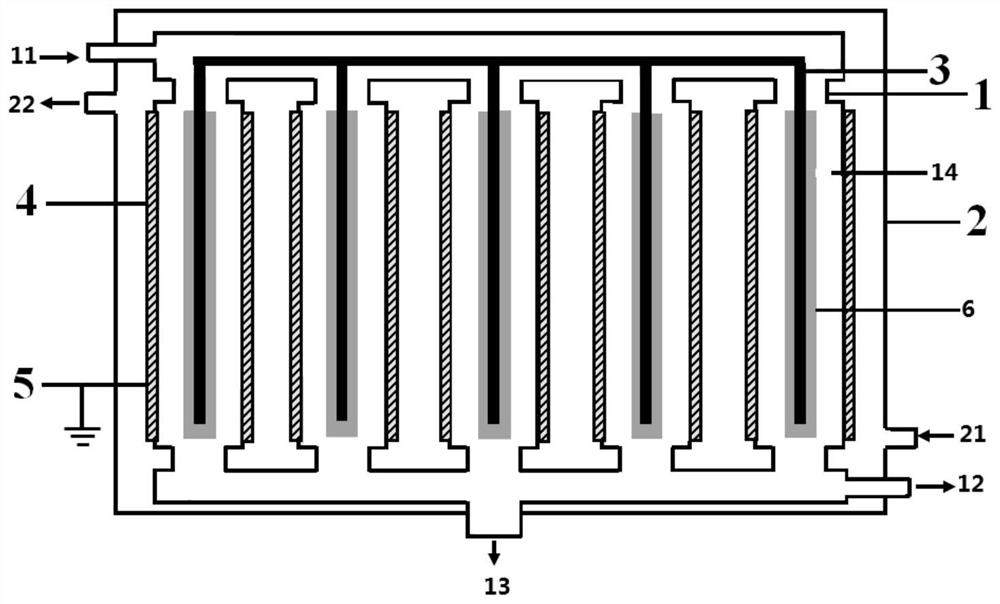

[0169] use has image 3 The high-throughput low-temperature plasma system for decomposing hydrogen sulfide in the flow chart shown in the flow chart performs the hydrogen sulfide decomposition reaction, and the low-temperature plasma reactor in this embodiment has figure 2 structure shown.

[0170] The process flow of this embodiment is as shown in the aforementioned specific implementation, and the structural parameters of the low-temperature plasma reactor are as follows:

[0171] Low temperature plasma reactors include:

[0172] An inner cylinder, the inner cylinder is respectively provided with a reactor inlet, a gas product outlet and a liquid product outlet, and the inner cylinder contains 4 reaction tubes arranged side by side, and the top and bottom of each of the reaction tubes communicate with each other correspondingly, The raw materials that enter from the inlet of the reactor can enter into each of the reaction tubes respectively, and the gaseous products produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com