Electric heating air filtration element and low-energy-consumption high-temperature disinfection and sterilization device for air

An air filter element and electric heating technology, applied in the field of air purification, can solve the problems of high power consumption, increase the complexity of the device, and short airflow retention time, and achieve the effect of reducing power consumption and improving economic and practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

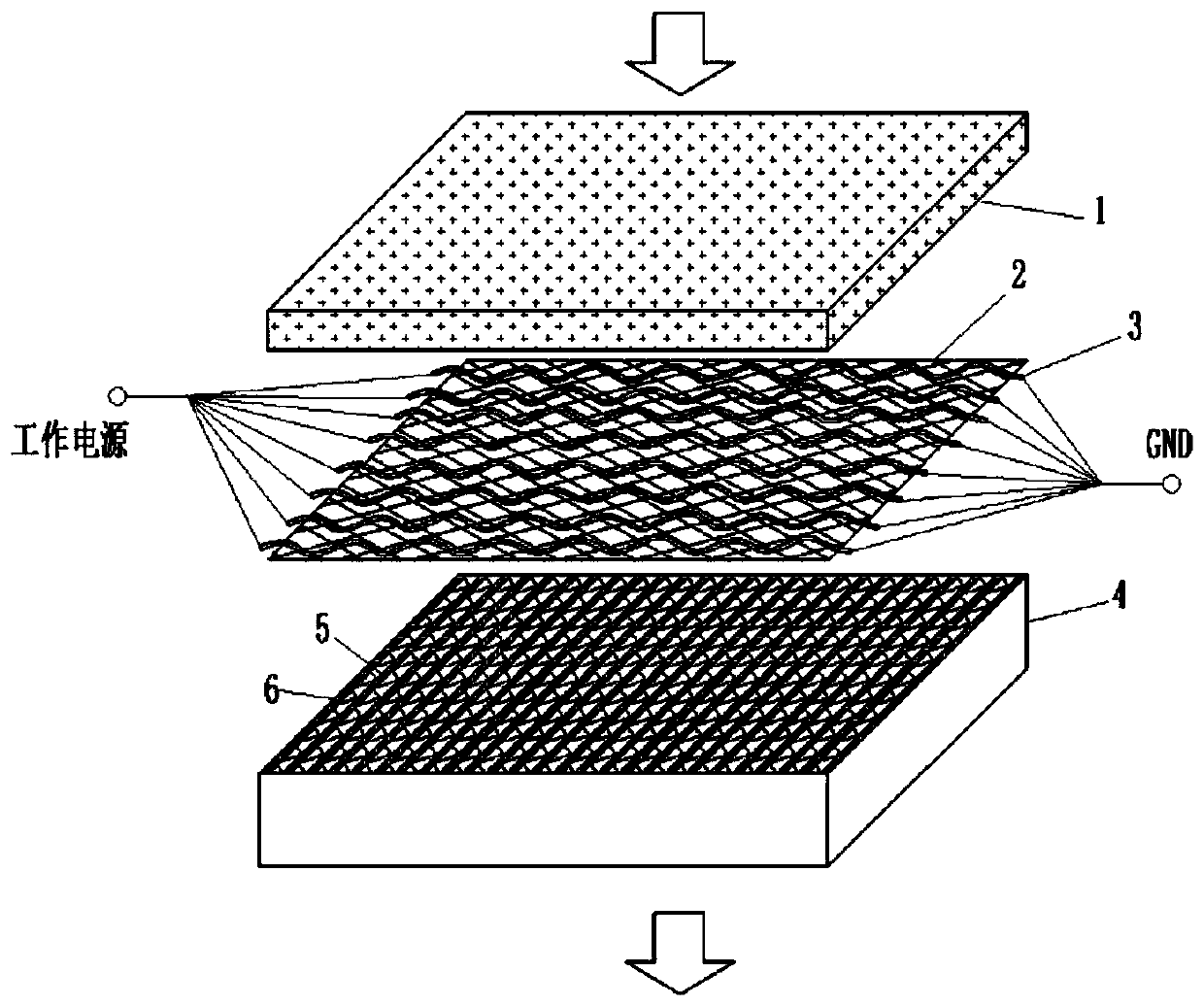

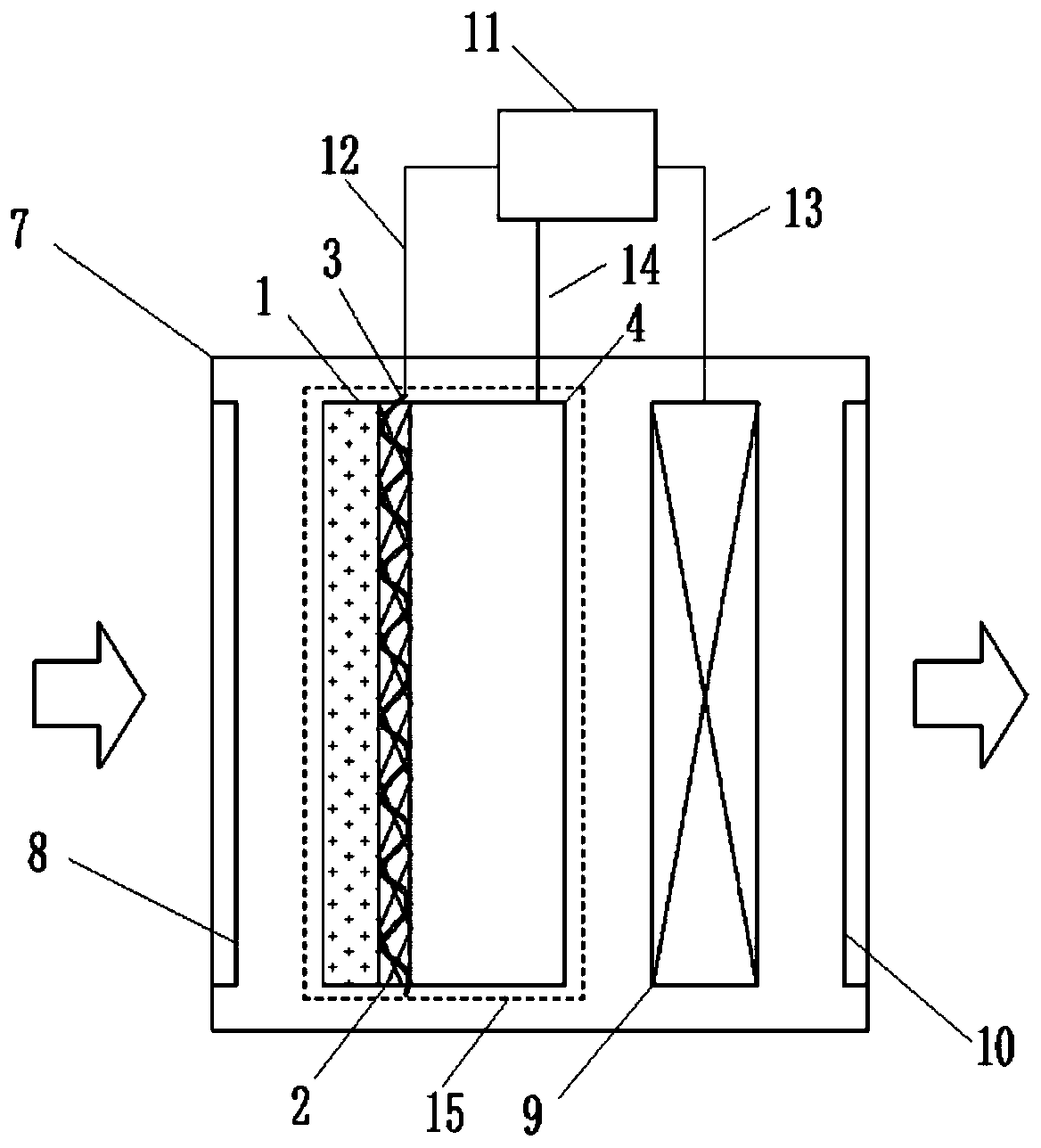

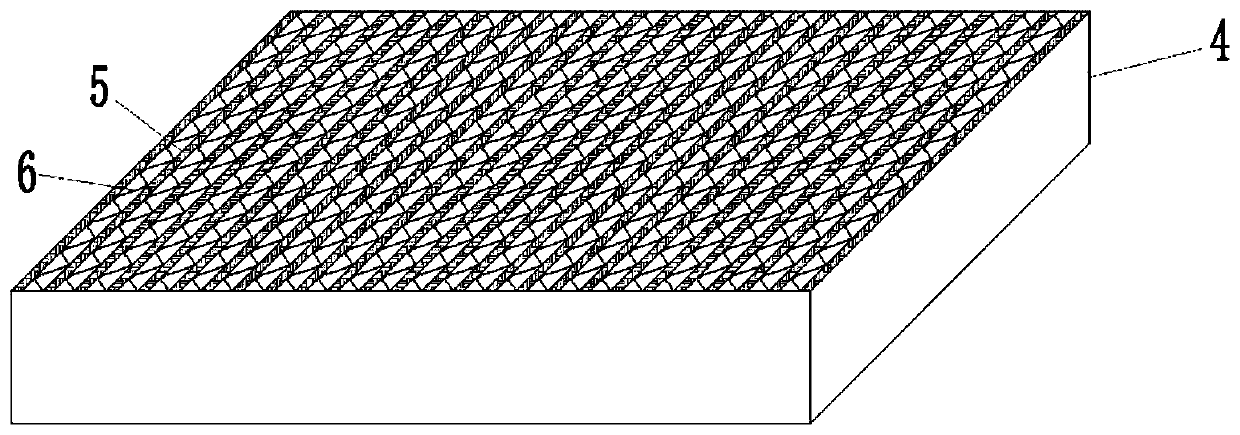

[0024] Such as figure 1 As shown, an electric heating air filter element is disclosed in one embodiment of the present invention, which includes: a high temperature resistant primary filter cotton 1 , a metal aluminum mesh 2 , an insulating heating wire 3 , and a high temperature resistant high efficiency air filter element 4 . Among them, the high-temperature-resistant high-efficiency air filter element 4 is assembled with high-temperature-resistant filter paper 5 made of glass fiber or ultra-fine glass fiber, aluminum foil separator 6, stainless steel frame, and special high-temperature-resistant sealant. The high temperature resistant filter paper 5 is pleated at 180° on both sides an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com