Hardware drilling equipment

A drilling equipment and hardware technology, applied in the hardware field, can solve the problems of drilling head and objects damage, rigid slippage, etc., and achieve the effect of preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

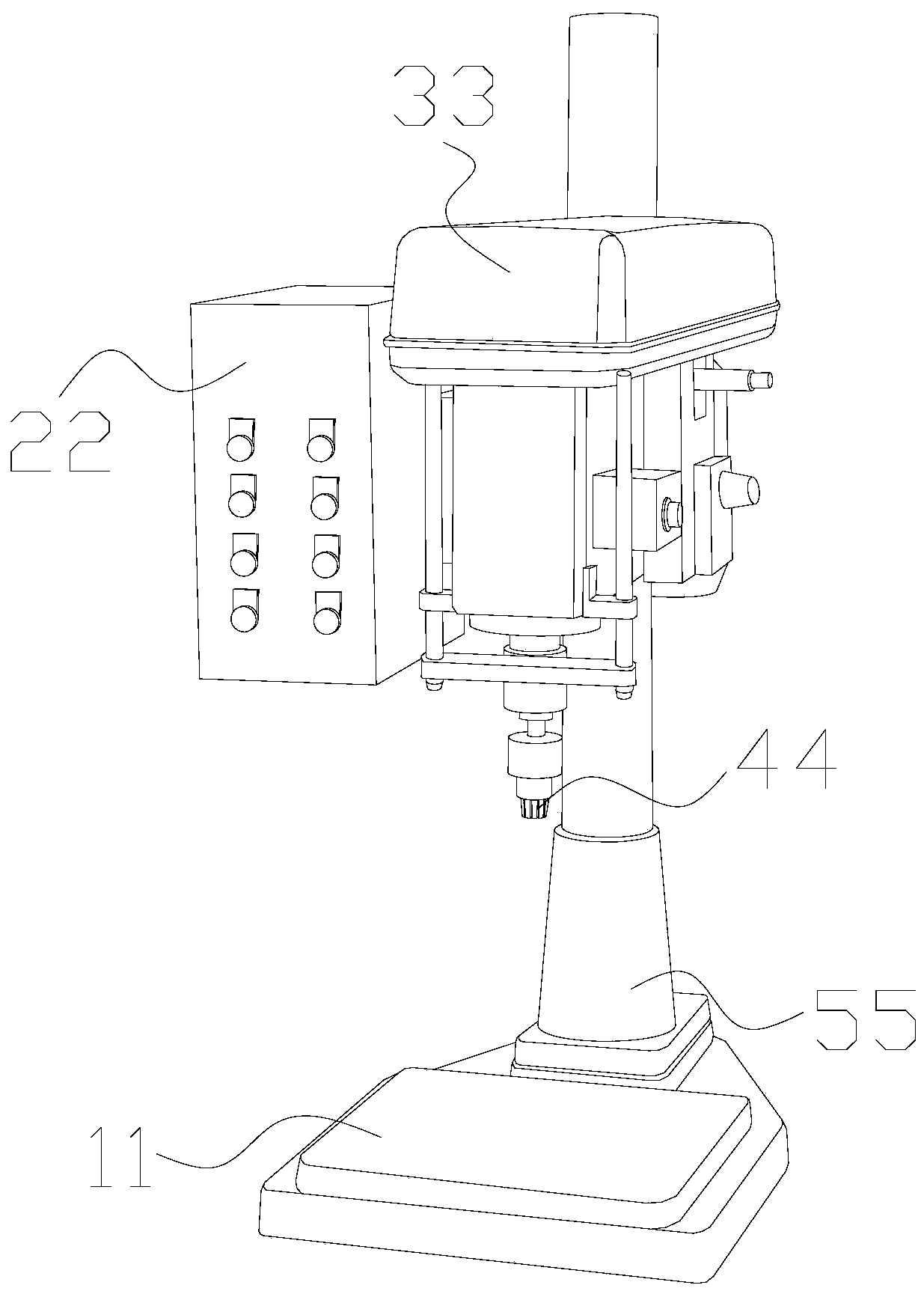

[0031] as attached figure 1 to attach Figure 5 Shown:

[0032] The present invention provides a hardware drilling device, the structure of which includes a workbench 11 , a console 22 , an implementing end 33 , a drilling head 44 , and a support rod 55 .

[0033] The upper surface of the workbench 11 is vertically welded with a support rod 55, and the end of the support rod 55 away from the workbench 11 is connected to the implementation end 33, and the lower end of the implementation end 33 is penetrated with a drilling head 44. The console 22 It is welded to the side surface of the implementation end 33.

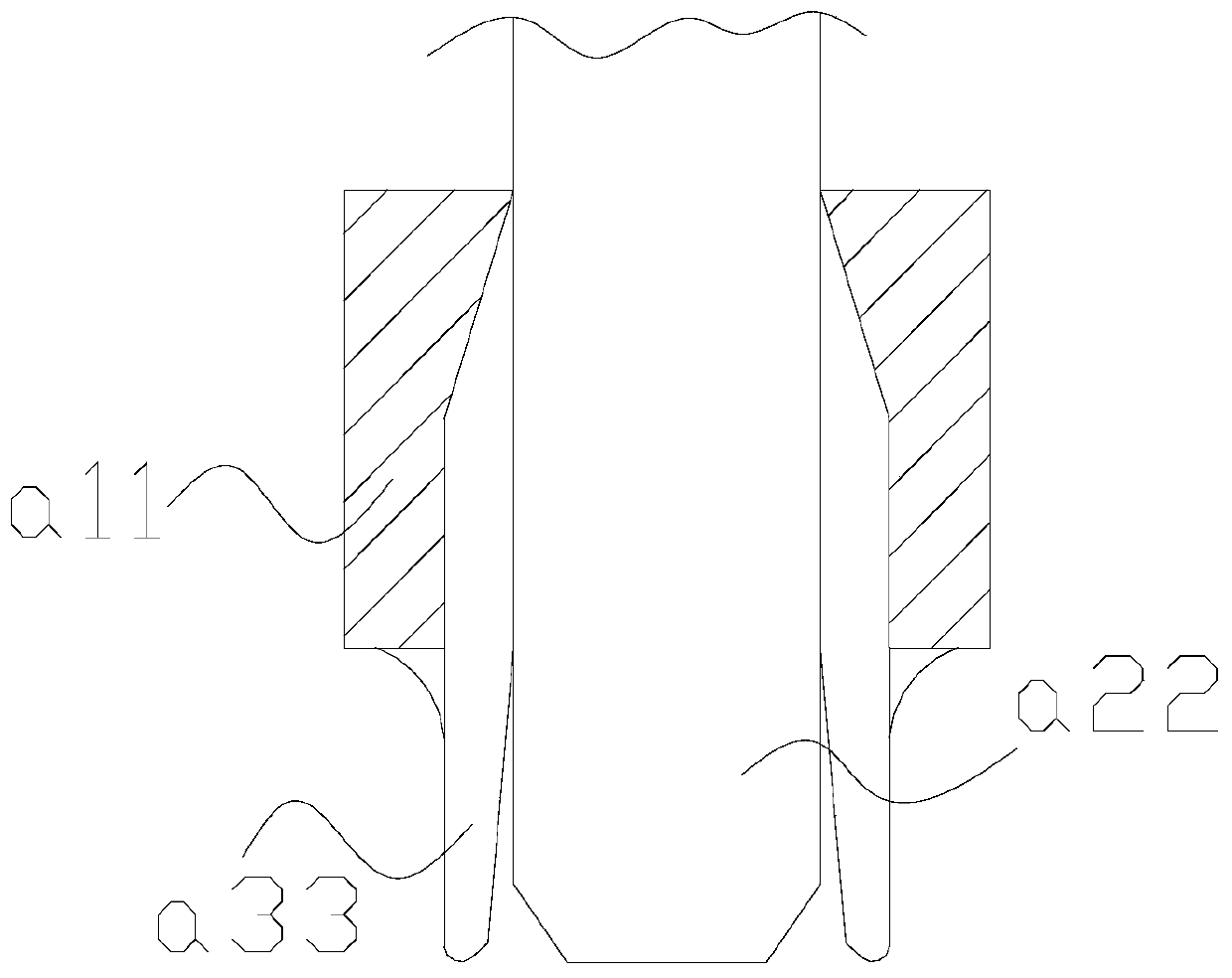

[0034] Wherein, the drilling head 44 includes an outer limiting shell a11, a drill body a22, and a supporting edge a33. The supporting edge a33 is against the outer surface of the drill body a22. The inner wall of the limit case a11, the support edge a33 evenly surrounds the outer surface of the drill body a22, the outer limit case a11 limits the overall expansion and ...

Embodiment 2

[0041] as attached Figure 6 to attach Figure 8 Shown:

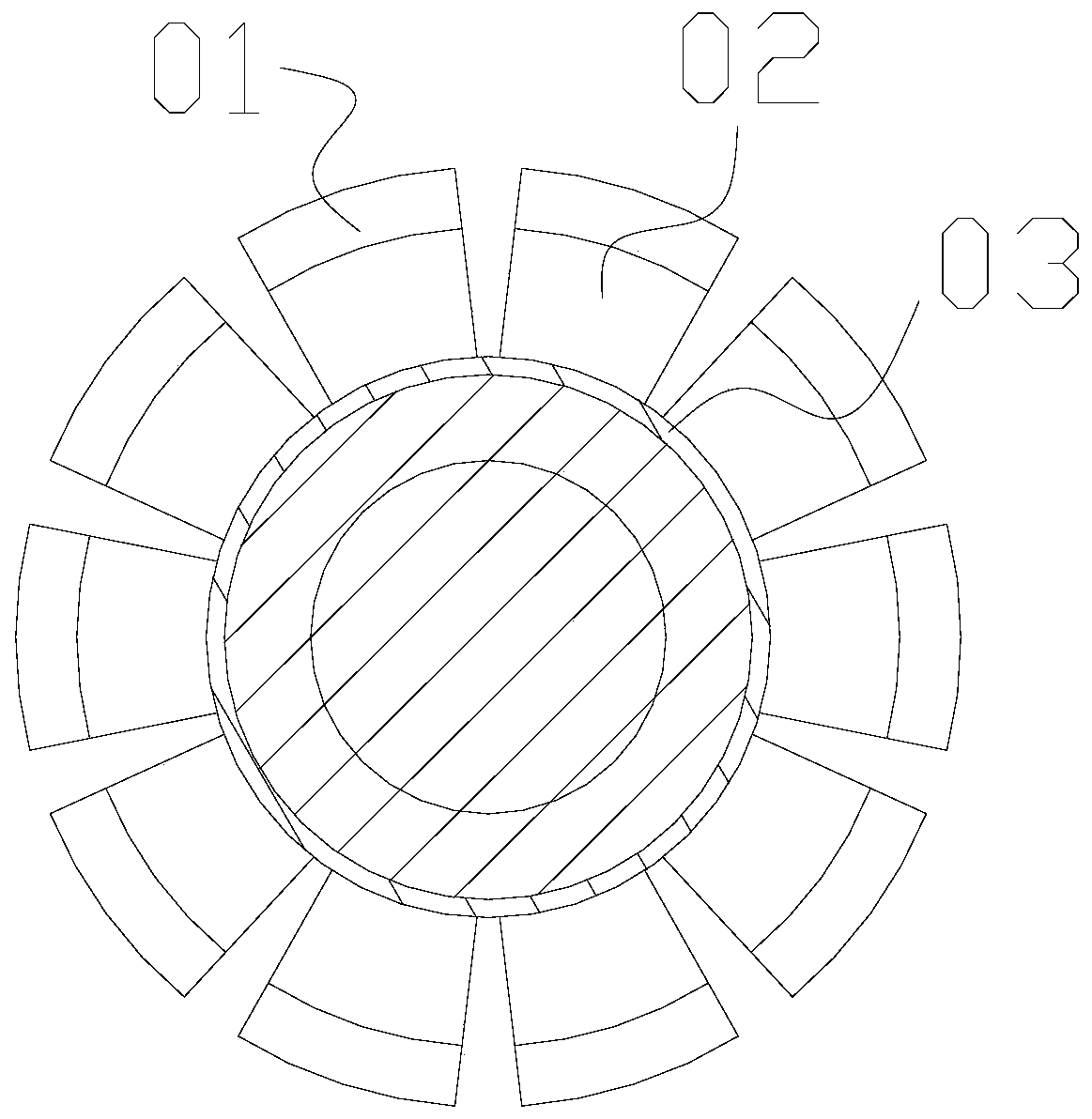

[0042] Wherein, the swing angle w22 includes a spacer e1, a force core e2, and an outer covering layer e3, the outer covering layer e3 is attached to the outer surface of the force core e2, and spacers are installed between the force cores e2 The strip e1, the force core e2 has a triangular structure and is evenly distributed in a fan shape, and the spacers e1 evenly space the active parts, and the force core e2 follows the arc required by the outer layer for bending and stretching.

[0043] Wherein, the force core e2 includes a return-shaped core m21 and an open angle m22. The return-shaped core m21 is against the outer surface of the open angle m22. The return-shaped core m21 is made of soft rubber material and has a certain degree of extrusion. Compression and resilience, the opening angle m22 bears the force on both sides and presses towards the middle, and the return-shaped core m21 gives the outer layer a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com