Vacuum arc plating device for shortening cooling time of target material

A cooling time and vacuum arc technology, applied in the field of coating, can solve the problems of poor coating quality of workpieces and long coating time of workpieces, improve performance and quality, improve production safety and equipment life, and improve coating uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

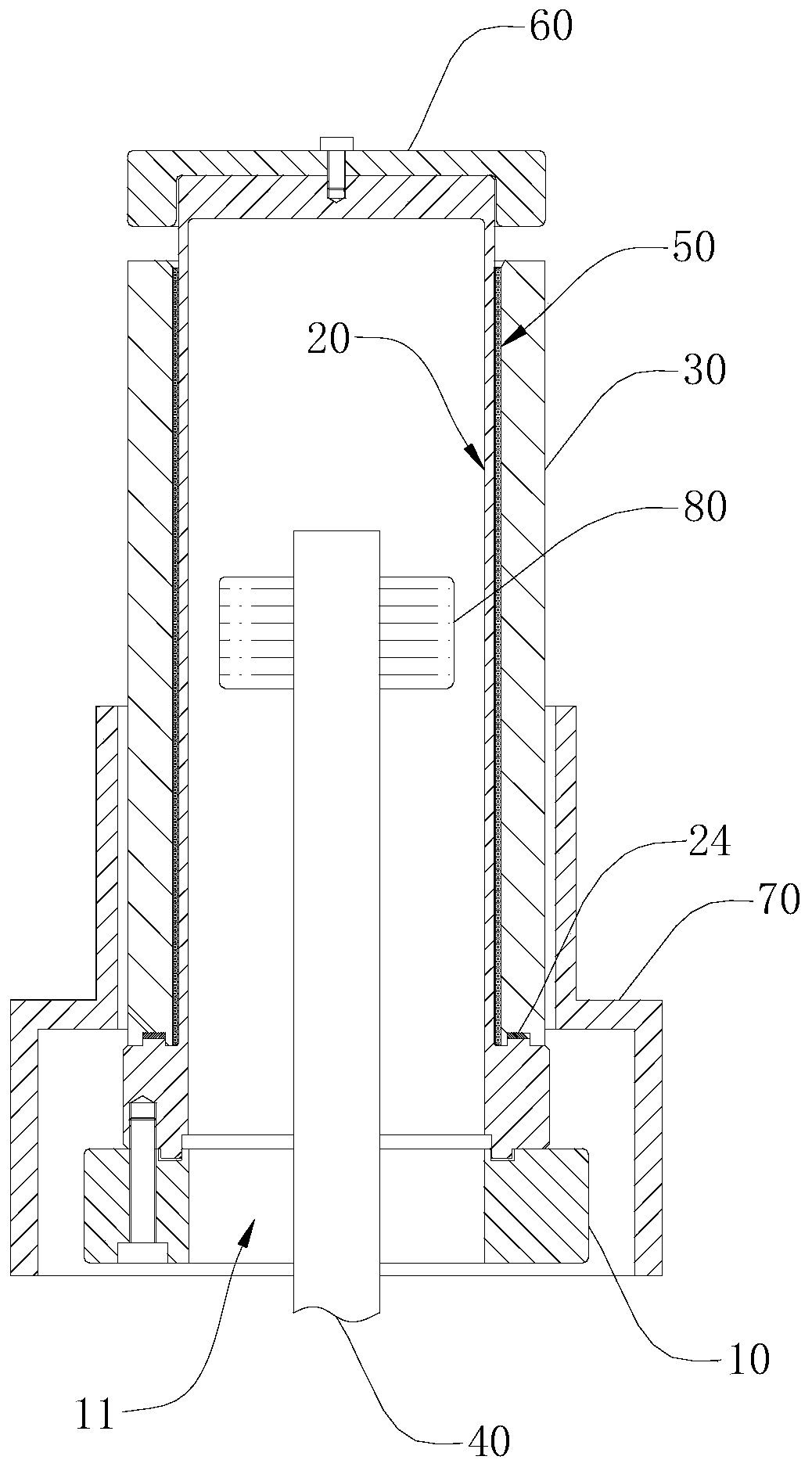

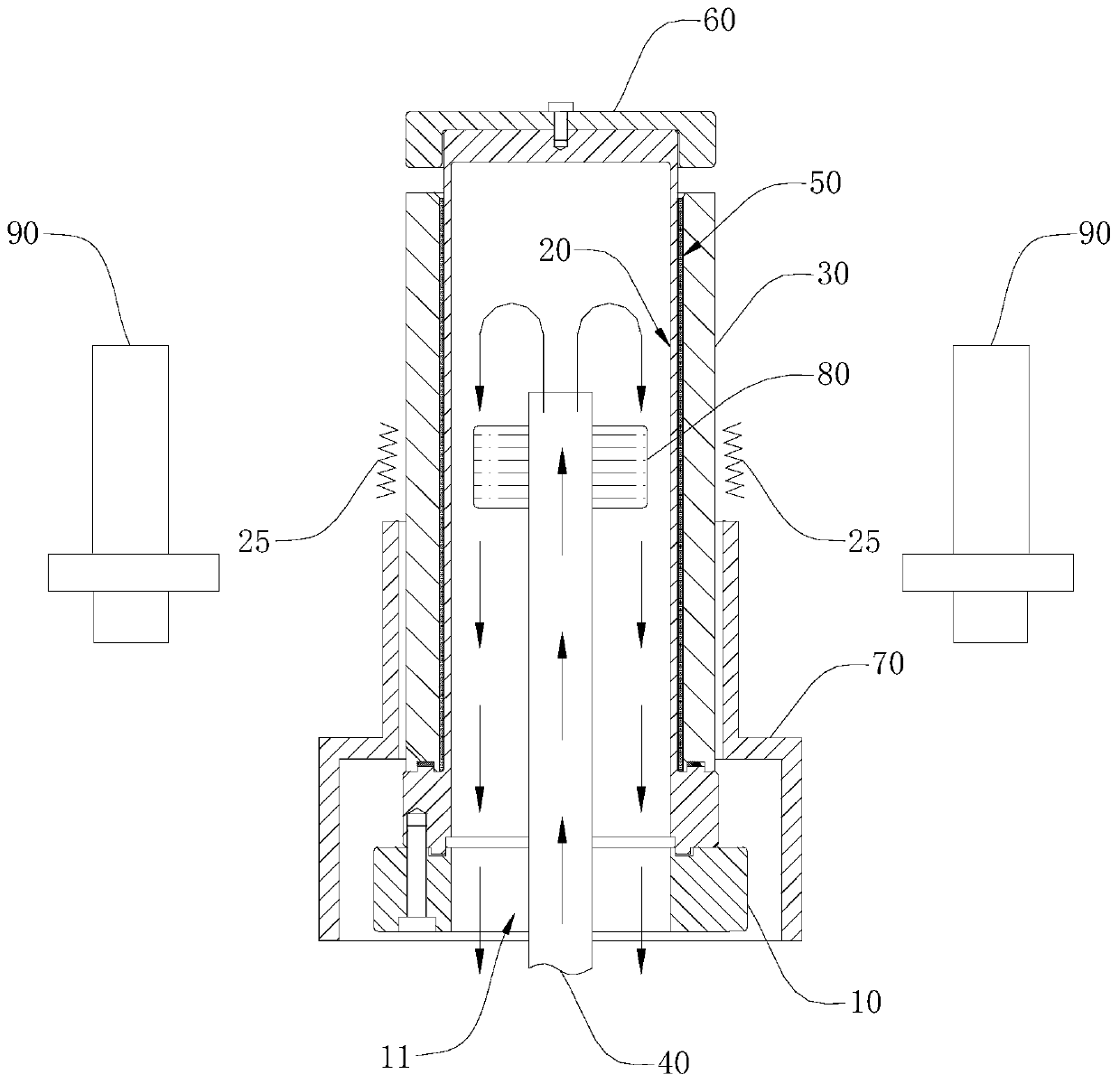

[0039] Please refer to figure 1 and figure 2 , a vacuum arc plating device for reducing the cooling time of a target, comprising: a base 10 , an installation seat 20 , a target 30 and a pipeline 40 . A through hole 11 is defined in the middle of the base 10 . The mounting base 20 is in the shape of a cylinder with a top seal, the bottom of the mounting base 20 is connected to the top of the base 10 through bolts, and the inside of the mounting base 20 communicates with the through hole 11 . The target material 30 is ring-shaped, and it covers the outside of the mounting base 20 , and a low-melting conductive filling layer 50 is provided between the target material 30 and the mounting base 20 . The pipe 40 protrudes from the through hole 11 into the inside of the mounting base 20 .

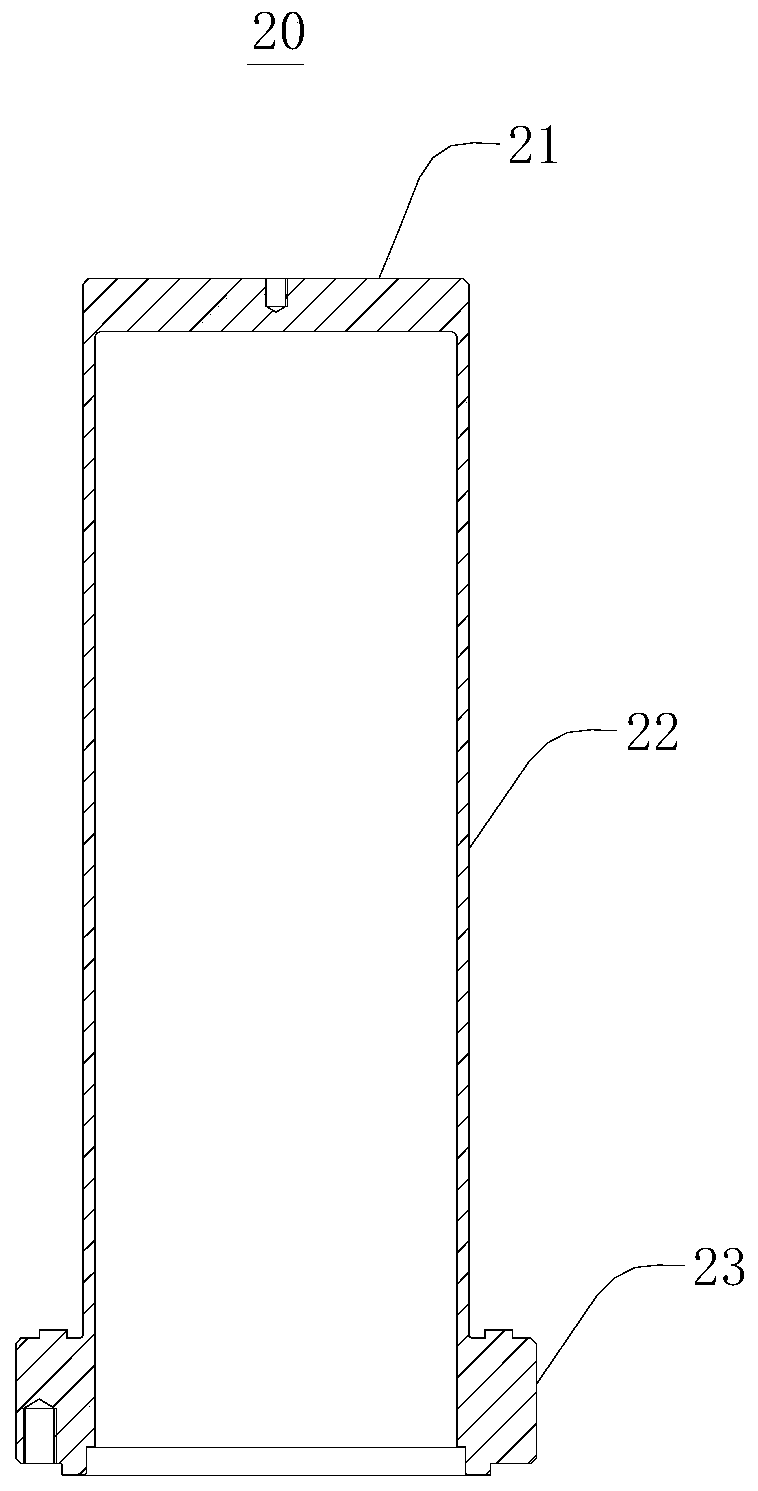

[0040] The mounting base 20 includes a top cover 21 , a limiting cylinder 22 and a limiting seat 23 arranged in sequence from top to bottom. The outer side of the top cover 21 is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com