Coated cutting tool

A cutting tool and coating technology, applied in the direction of manufacturing tools, workpieces, drilling tool accessories, etc., can solve problems such as inability to extend tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to these examples.

[0099] As a substrate, prepare a CNMG120412 shape with 88.9WC-7.9Co-1.5Ti N-1.4NbC-0.3Cr 3 C 2 Cemented carbide cutting inserts having a composition of (above is mass %) and having a shape of CN MG120412 and having 89.7WC-7.1Co-1.5TiN-1.5NbC-0.2Cr 3 C 2 (The above is the mass %) cutting insert made of cemented carbide. After performing fillet honing on the edge portion of the base material with a SiC brush, the surface of the base material was cleaned.

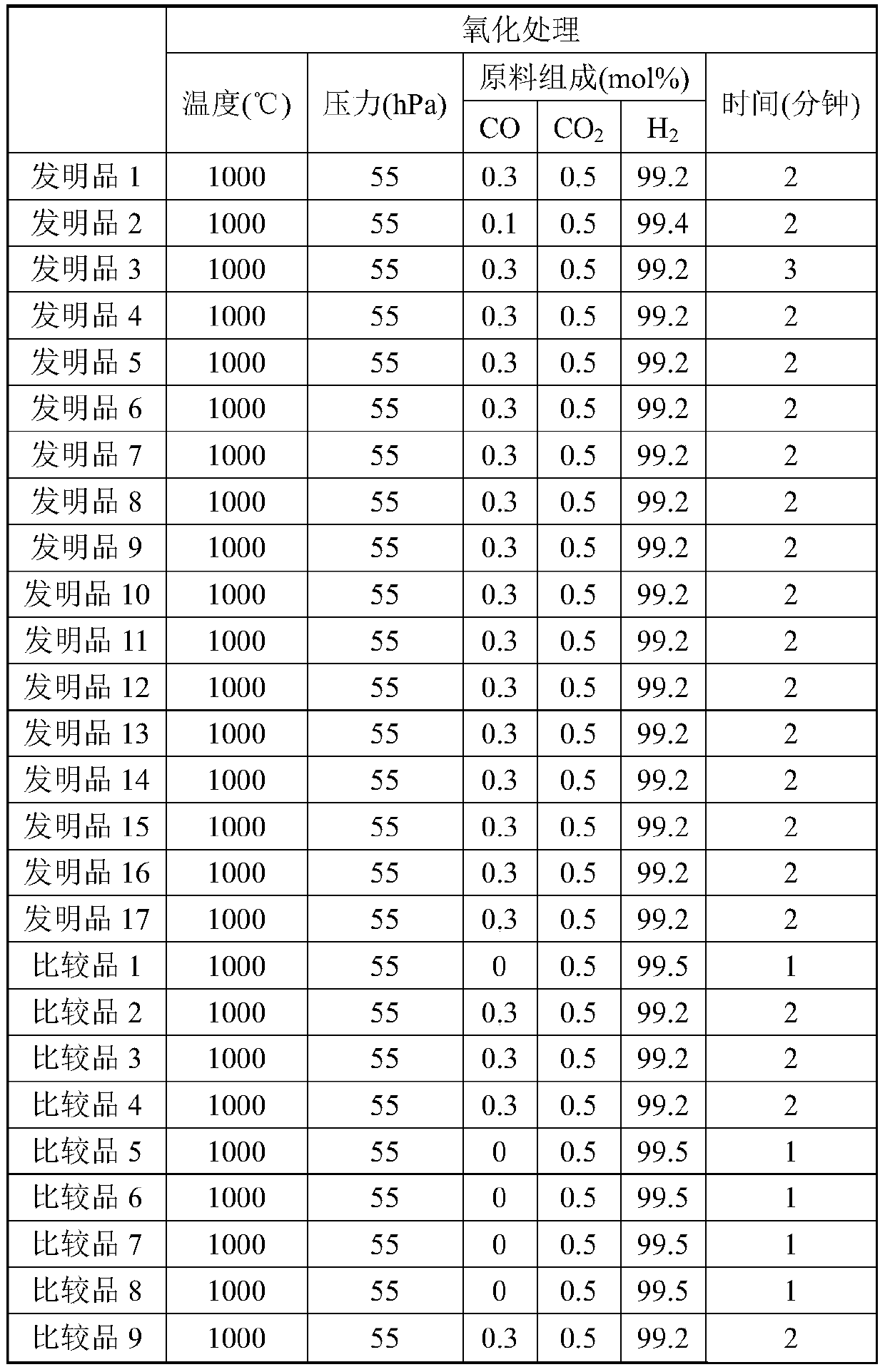

[0100] [Invention products 1-17 and comparative products 1-9]

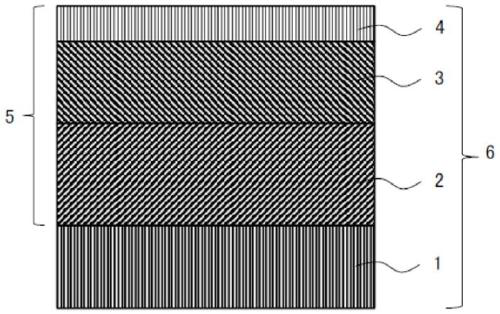

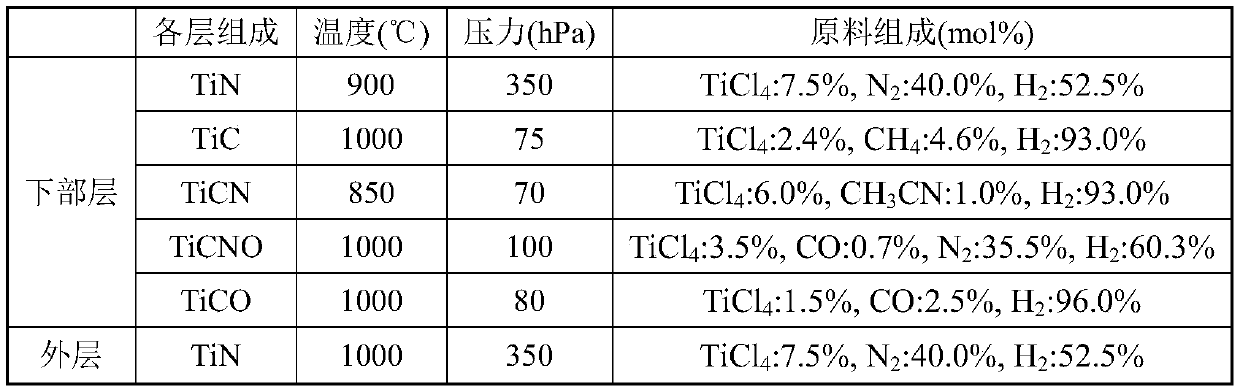

[0101] After cleaning the surface of the substrate, a coating layer is formed by chemical vapor deposition. First, put the substrate into an external thermal chemical vapor deposition device, and form the composition shown in Table 6 on the surface of the substrate with the average thickness shown...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap