Method of preparing bionic photonic crystal structure color-generating textile

A technology of crystallization and structural coloration, applied in textiles, papermaking, coatings, etc., can solve few problems such as few, and achieve the effects of improving connection, enhancing bonding, improving stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

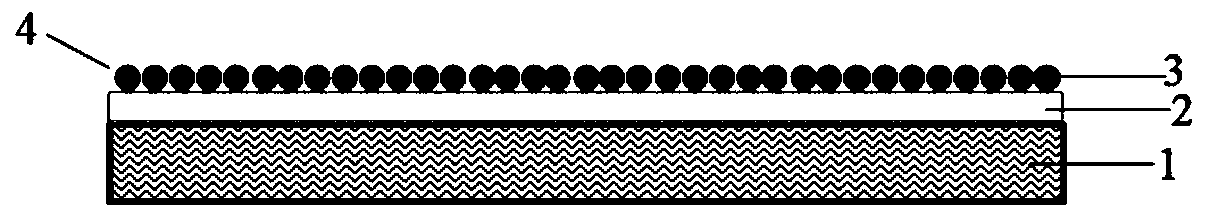

[0032] This embodiment provides a method for preparing a bionic photonic crystal structure chromogenic polypropylene nonwoven fabric, the specific steps are as follows:

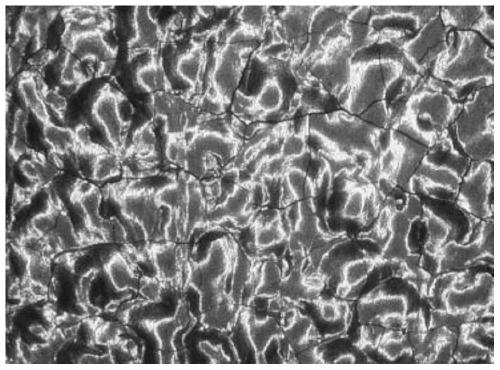

[0033] (1) Preparation of transparent self-crosslinking polyacrylate film layer: adding pure water to a self-crosslinking polyacrylate emulsion with a solid content of 45%, and preparing it to a concentration of 10% (by mass fraction) finishing solution, and then cast the finishing solution on a grammage of 150g / m 2 The surface of the white polypropylene non-woven fabric is dried in a medium oven at 120°C;

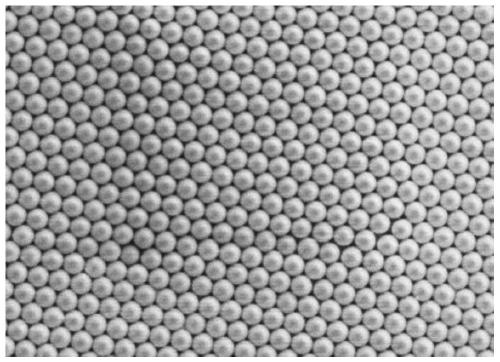

[0034] (2) Preparation of biomimetic photonic crystal chromogenic structure layer: centrifuge monodisperse black polystyrene nanospheres with a solid content of 30% and a particle size of 240nm, pour out the supernatant, and remove the sticky substance and mass fraction of the lower layer 10% polyvinyl alcohol aqueous solution is mixed evenly in a weight ratio of 40:100, and then it is scraped by a coati...

Embodiment 2

[0039] This embodiment provides a method for preparing a bionic photonic crystal structure chromogenic polypropylene nonwoven fabric, the specific steps are as follows:

[0040] (1) Preparation of transparent self-crosslinking polyacrylate film layer: adding pure water to a self-crosslinking polyacrylate emulsion with a solid content of 45%, and preparing it to a concentration of 15% (by mass fraction) finishing solution, and then cast the finishing solution on a grammage of 180g / m 2 The surface of the white polypropylene non-woven fabric is dried in a medium oven at 120°C;

[0041] (2) Preparation of biomimetic photonic crystal chromogenic structural layer: centrifuge monodisperse black poly(styrene-methacrylic acid) nanospheres with a solid content of 30% and a particle size of 300 nm, pour out the supernatant, and remove the lower layer The sticky substance and 10% polyvinyl alcohol aqueous solution are uniformly mixed in a weight ratio of 45:100, and then it is scraped by...

Embodiment 3

[0045] This embodiment provides a method for preparing a bionic photonic crystal structure chromogenic polypropylene nonwoven fabric, the specific steps are as follows:

[0046] (1) Preparation of transparent self-crosslinking polyacrylate film layer: adding pure water to a self-crosslinking polyacrylate emulsion with a solid content of 45%, and preparing it to a concentration of 20% (by mass fraction) finishing solution, and then cast the finishing solution on a grammage of 200g / m 2 The surface of the white polypropylene non-woven fabric is dried in a medium oven at 120°C;

[0047] (2) Preparation of biomimetic photonic crystal chromogenic structure layer: centrifuge monodisperse black (polystyrene-butyl acrylate-methacrylic acid) nano-microspheres with a solid content of 30% and a particle size of 175 nm and pour out the supernatant liquid, remove the layer of sticky material and mix it with 10% polyvinyl alcohol aqueous solution in a weight ratio of 50:100, and then scrape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com