Downhole strain distribution monitoring system based on distributed optical fiber sensing and monitoring method

A distributed optical fiber and strain distribution technology, applied in the field of strain measurement, can solve the problem of being unsuitable for multi-point strain measurement, and achieve the effects of long measurement distance, low cost, and improved real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not intended to limit the present invention, but are merely examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

[0043] A specific embodiment of a downhole strain distribution monitoring system based on distributed optical fiber sensing of the present invention is as follows:

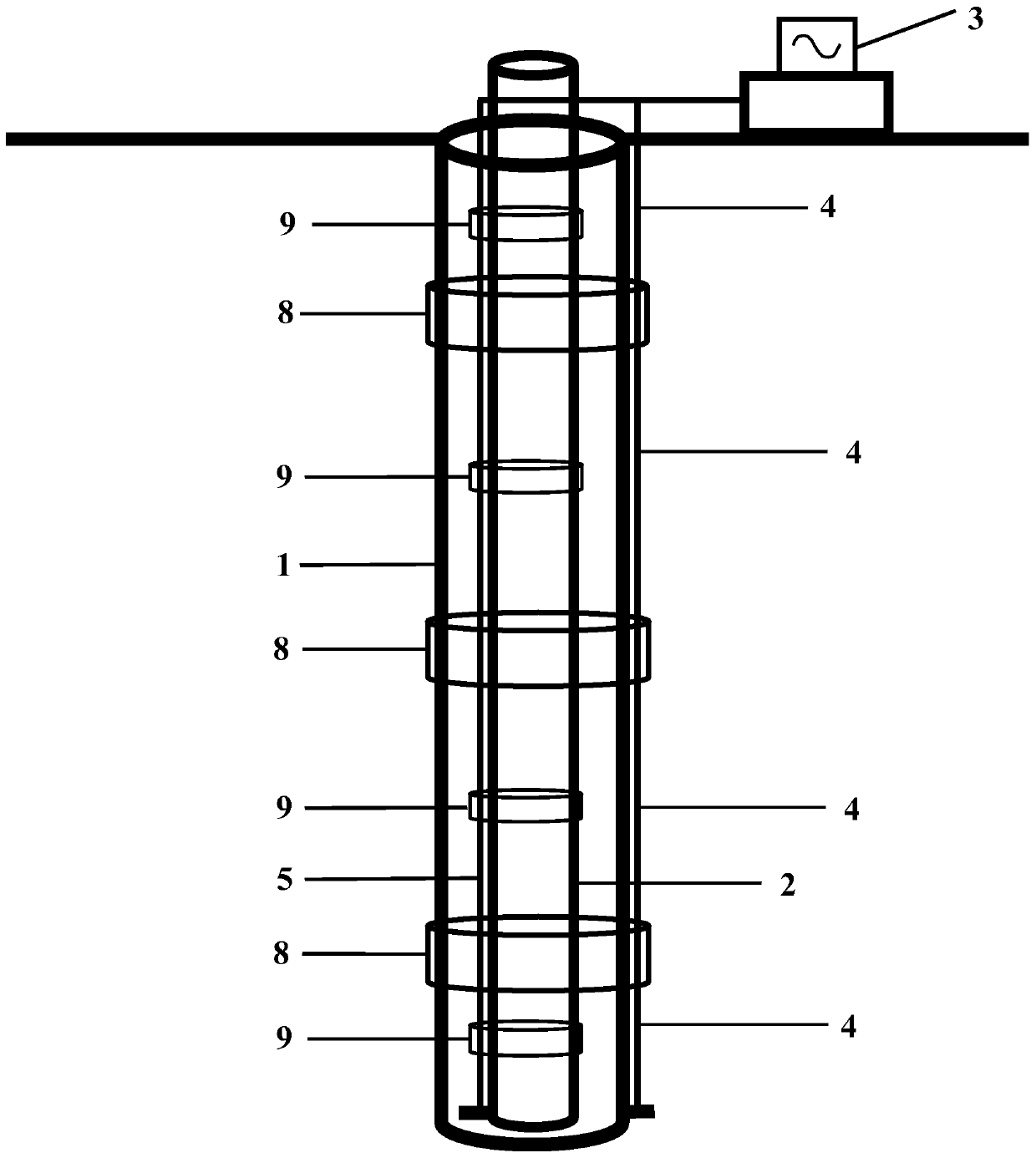

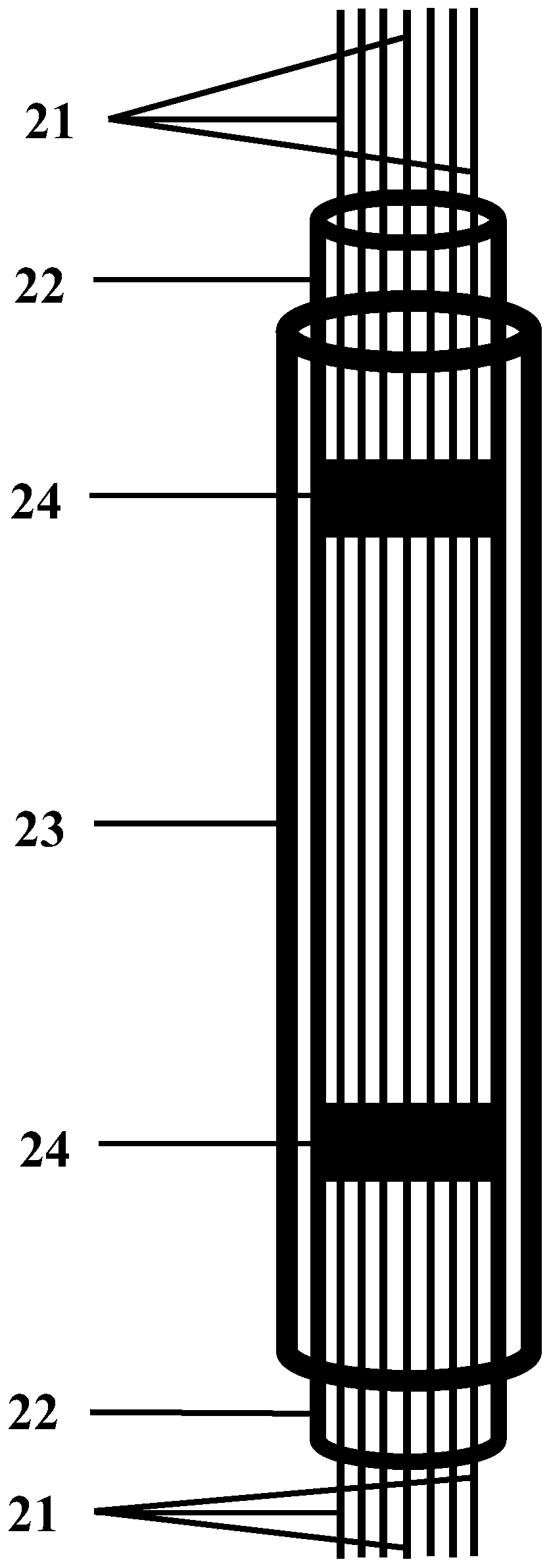

[0044] Such as figure 1 As shown, the downhole strain distribution monitoring system based on distributed optical fiber sensing includes a metal casing 1, a coiled tubing 2 built into the metal casing 1, and a DSS / DTS composite modulation and demodulation instrument 3 placed near the wellhead. DSS / DTS composite modem instrument 3 includes data acquisition and modem functions of distributed strain sensing and distributed temperature sensing.

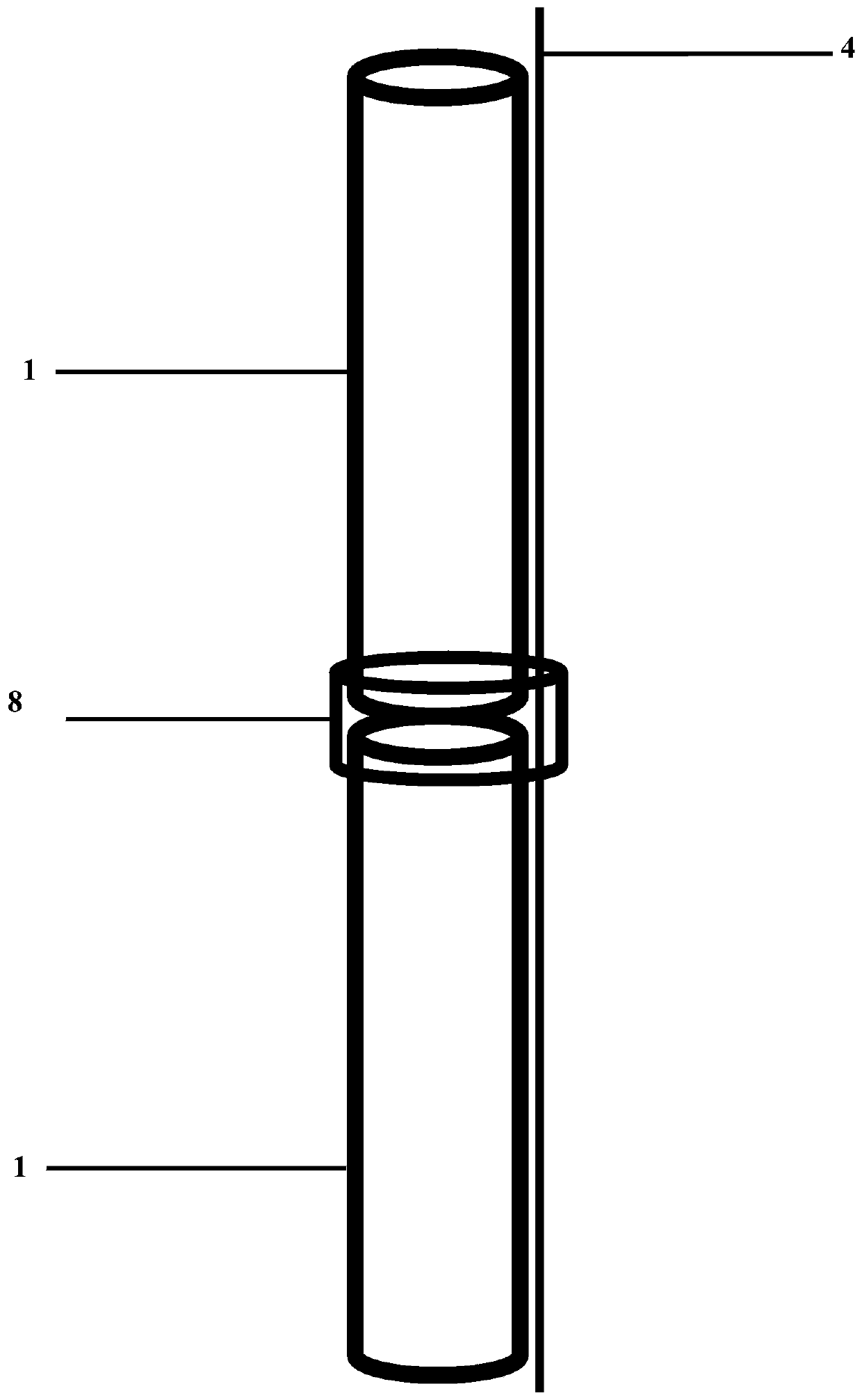

[0045] It also includes a first armored optical cable 4 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com