Method for manufacturing super absorbent resin sheet and super absorbent resin sheet manufactured thereby

A polymer sheet, super-absorbent technology, used in absorbent pads, medical science, bandages, etc., can solve the problems of dispersion or leakage, limited use range, etc., and achieve the effect of improving absorption rate and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

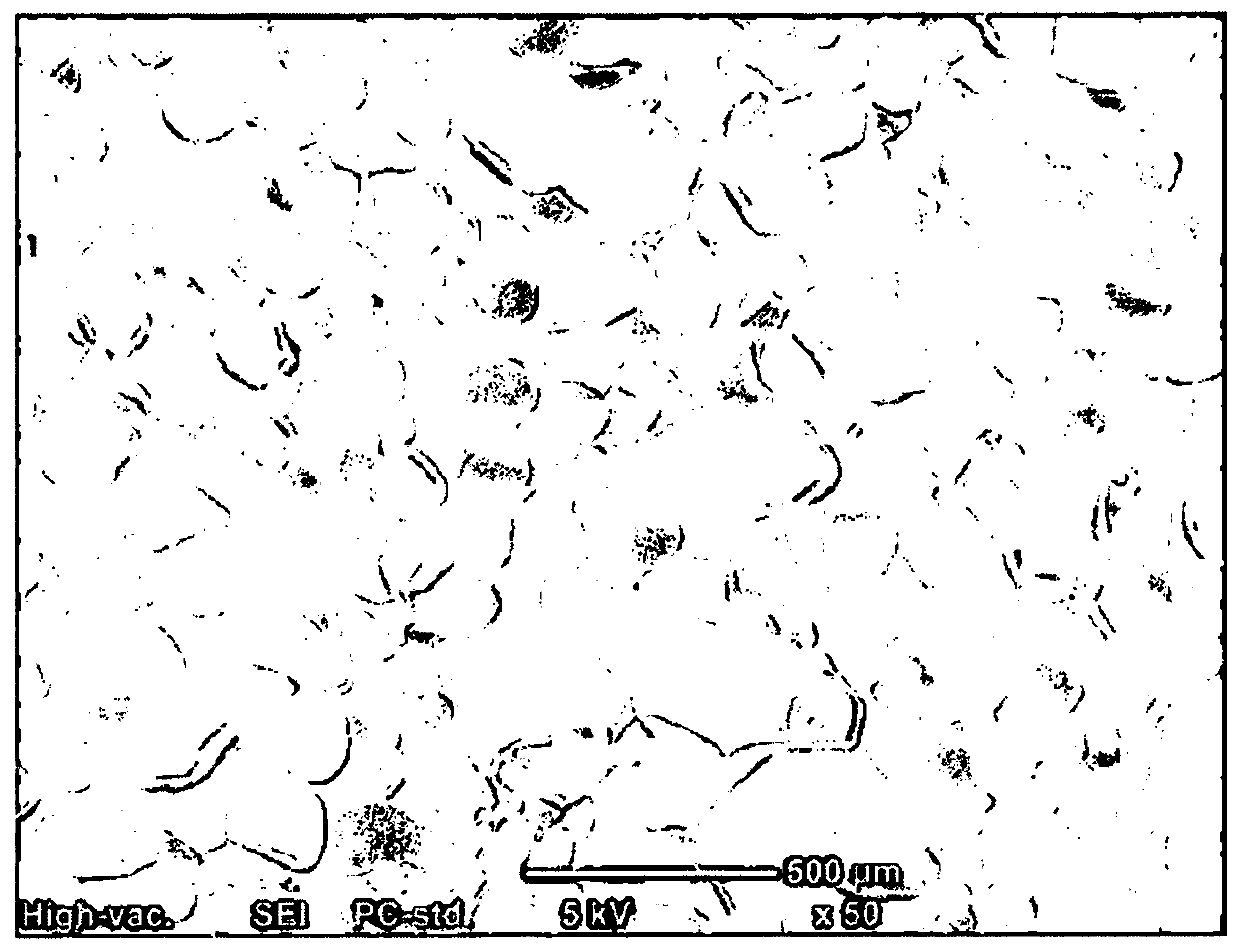

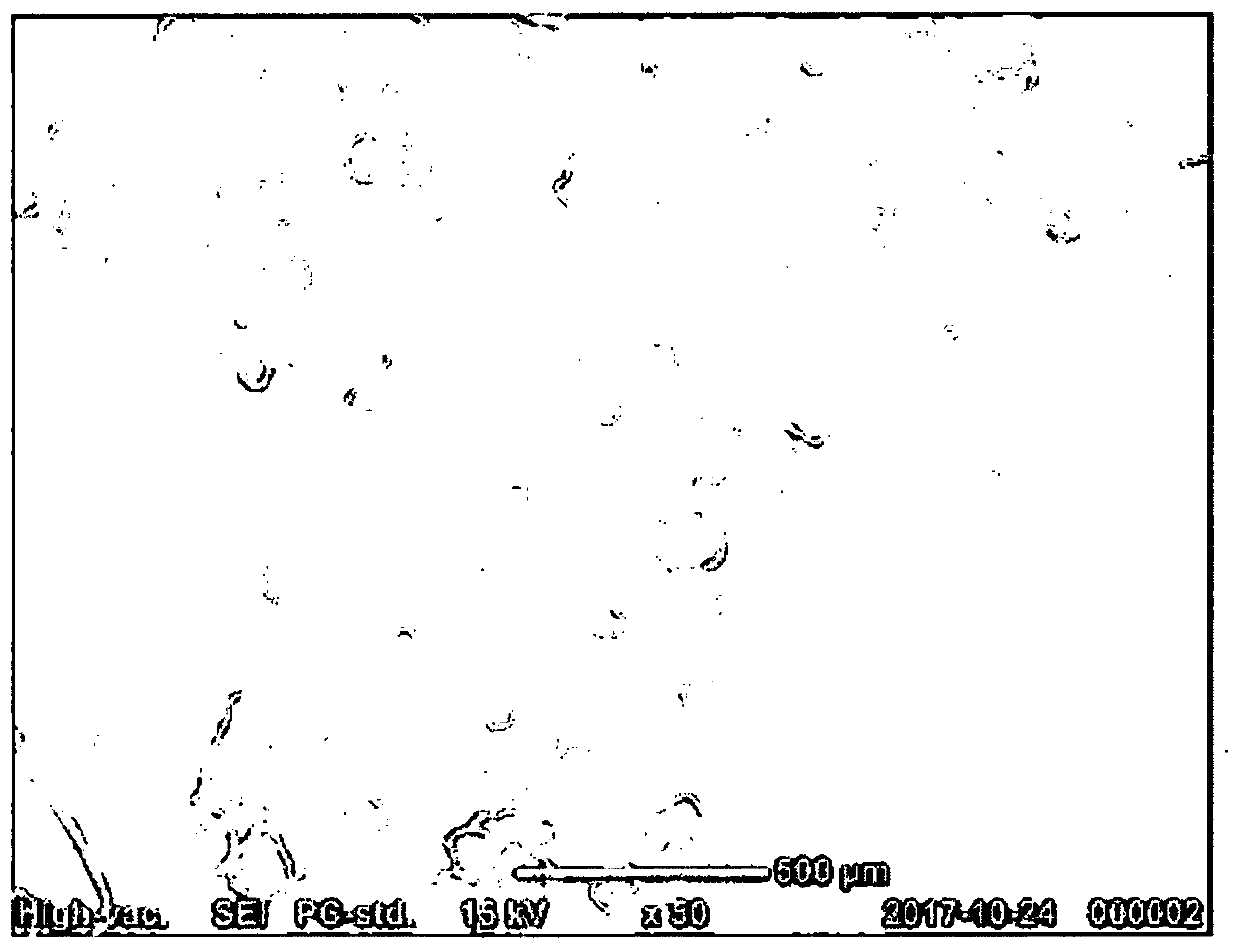

[0027] According to one embodiment of the present disclosure, there is provided a method of making a superabsorbent polymer sheet, comprising the steps of: preparing a monomer composition comprising a polymer having at least partially neutralized acidic groups Acrylic-based monomers, polyethylene glycol (methyl ether) (meth)acrylate-containing comonomers, polyol-containing internal crosslinking agents, encapsulated blowing agents, and polymerization initiators; by using The hydrogel polymer is prepared by thermally polymerizing or photopolymerizing the monomer composition; and the hydrogel polymer is dried to form a superabsorbent polymer sheet.

[0028] In the present disclosure, the monomer composition as a raw material for the superabsorbent polymer includes an acrylic-based monomer having an at least partially neutralized acidic group, a polyethylene glycol (methyl ether) (methyl ether) ) comonomers of acrylates, polyol-containing internal crosslinkers, encapsulated blowin...

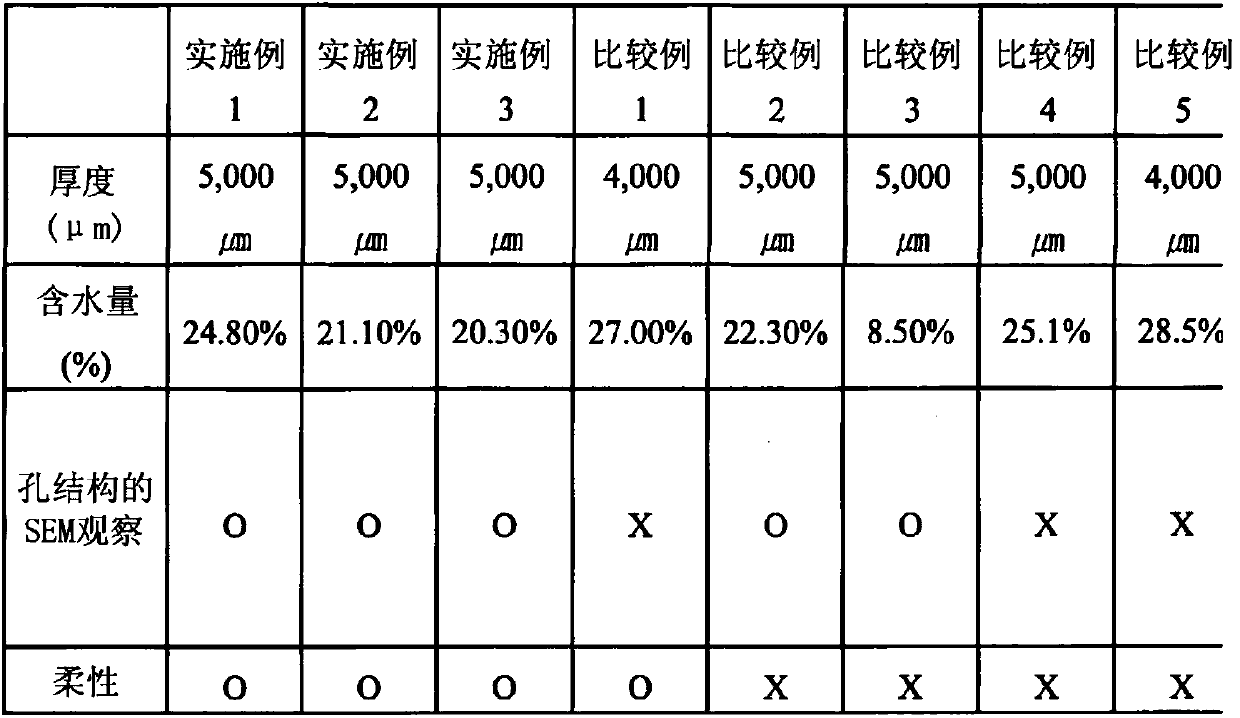

Embodiment 1

[0090] 35.3 g of acrylic acid, 43.5 g of sodium hydroxide (NaOH, 30 wt % solution), and 7.7 g of water were mixed to prepare a neutralized solution (solid content: 56 wt %) in which about 70 mol % of acrylic acid was neutralized.

[0091] To the neutralized solution were added 7.1 g of polyethylene glycol (methyl ether) (meth)acrylate (product name: FA-401, manufacturer: Hannong Chemicals) as a comonomer, 10 g of glycerin, 0.06 g of polyethylene Diol diacrylate (MW=330, manufacturer: Aldrich) and 0.51 g of encapsulated blowing agent (grade 36D, manufacturer: Matsumoto) to prepare a monomer composition.

[0092] The monomer composition was high shear mixed using a mechanical mixer at 500 rpm for about 10 minutes.

[0093] Thereafter, the mixture is added through the feeder of the polymerization reactor to polymerize, thereby forming a hydrogel polymer. At this time, the temperature of the polymerization reactor was maintained at 100°C, the maximum temperature during the polyme...

Embodiment 2

[0097] A superabsorbent polymer sheet was prepared in the same manner as in Example 1, except that 20 g of glycerin was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com