Optical laminate and flexible display device including the same

A technology of optical laminates and chemical formulas, applied in optics, identification devices, optical components, etc., can solve problems such as high curing shrinkage, increased pressure of hard coating film, and severe curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0143]3-glycidoxypropyltrimethoxysilane (GPTMS, manufactured by Shin-Etsu Chemical Co., Ltd.), water (GPTMS: water = 1 mol: 3 mol) and toluene were added and stirred in a 1000 mL three-necked flask as a silane monomer. In the resulting mixed solution, 1 part by weight of a basic catalyst (TMAH) was added to 100 parts by weight of the silane monomer, and reacted at 100°C to prepare a modified silicone containing glycidoxypropyl group. (glycidoxypropyl modified silicone, hereinafter referred to as GP) 100 mole % polysiloxane (Mw: 2,700g / mol, Mn: 2,100g / mol, molecular weight distribution (Mw / Mn): 1.29, epoxy equivalent : 5.9g / eq)

[0144] (R 1 SiO 3 / 2 ) a (R 2 SiO 3 / 2 ) b (OR) c (1)

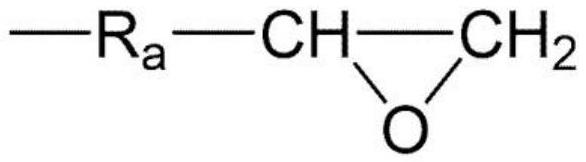

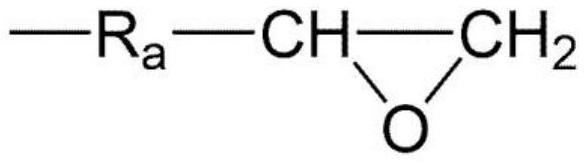

[0145] (In the above chemical formula 1, R 1 is glycidyl (in chemical formula 2, R'=each hydrogen atom, R"=methylene), a=1, b=0, c=0)

[0146] (a2) Polysiloxane: what was prepared according to the following synthesis example 2 was used.

Synthetic example 2

[0148] 250 g of 3-glycidoxypropyltrimethoxysilane (GPTMS, manufactured by Shin-Etsu Chemical Co., Ltd.) and methyltrimethoxysilane (MTMS, manufactured by Shin-Etsu Chemical Co., Ltd.) were placed in a 1000 mL three-necked flask as silane monomers. 140 g, water (GPTMS: MTMS: water = 1 mol: 3 mol: 0.97 mol) and 200 g of toluene were stirred. In the resulting mixed solution, 1 part by weight of a basic catalyst (TMAH) was added to 100 parts by weight of the silane monomer, and reacted at 100°C to prepare a modified silicone containing glycidoxypropyl group. (glycidoxypropyl modified silicone, hereinafter referred to as GP) 62 mole % polysiloxane (Mw: 2,300g / mol, Mn: 1,920g / mol, molecular weight distribution (Mw / Mn): 1.29, epoxy group equivalent : 2.95 / eq)

[0149] (R 1 SiO 3 / 2 ) a (R 2 SiO 3 / 2 ) b (OR) c (1)

[0150] (In the above formula, R 1 is glycidyl (in chemical formula 2, R'=each hydrogen atom, R"=methylene), R 2 is a methyl group, R is a hydrogen atom, a=0.62,...

Synthetic example 3

[0153] 350 g of 3-glycidoxypropyltrimethoxysilane (GPTMS, manufactured by Shin-Etsu Chemical Co., Ltd.) and methyltrimethoxysilane (MTMS, manufactured by Shin-Etsu Chemical Co., Ltd.) were placed in a 1000 mL three-necked flask as silane monomers. 61 g, water (GPTMS: MTMS: water == 1 mol: 0.3 mol: 0.3 mol) and 200 g of toluene were stirred. In the resulting mixed solution, 1 part by weight of a basic catalyst (TMAH) was added to 100 parts by weight of the silane monomer, and reacted at 100°C to prepare a modified silicone containing glycidoxypropyl group. (glyci doxypropyl modified silicone, hereinafter referred to as GP) 76 mol% polysiloxane (Mw: 3,200g / mol, Mn: 2,450g / mol, molecular weight distribution (Mw / Mn): 1.30, epoxy group Equivalent: 4.54 / eq)

[0154] (R 1 SiO 3 / 2 ) a (R 2 SiO 3 / 2 ) b (OR) c (1)

[0155] (In the formula, R 1 is glycidyl (in chemical formula 2, R'=each hydrogen atom, R"=methylene), R 2 is a methyl group, R is a hydrogen atom, a=0.76, b=0.23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com