Centrifugal extractor for solid-liquid phase system

A centrifugal extraction machine, solid-liquid phase technology, applied in the direction of centrifuge, liquid solution solvent extraction, solvent extraction, etc., can solve the problems of structural parameter change, no removal, production interruption, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

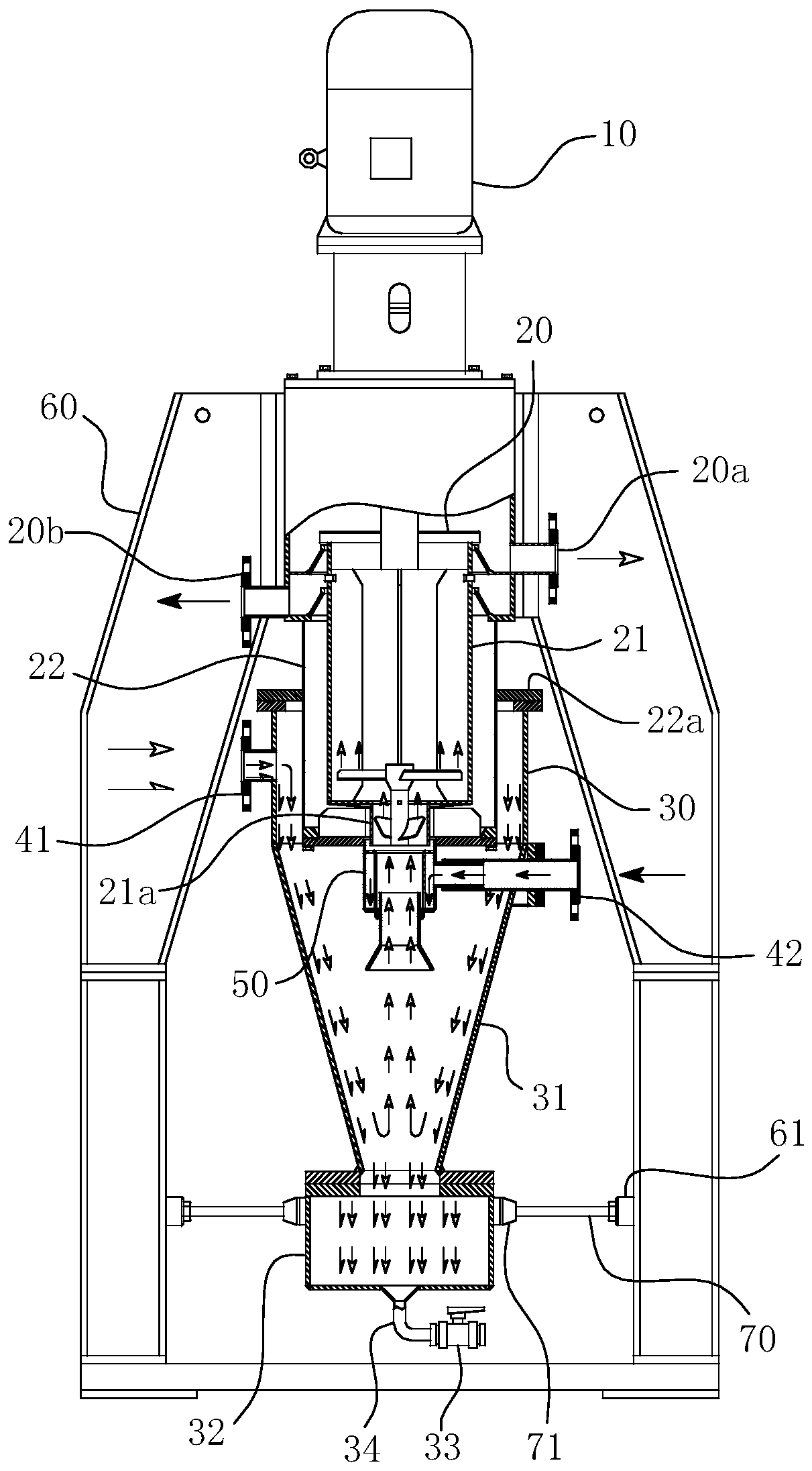

[0041] For ease of understanding, here the concrete structure of the present invention and working method are further described as follows:

[0042] The main part of the centrifugal extractor of the present invention, that is, the centrifugal extraction part 20, still follows the structure of the traditional centrifugal extractor. That is to say, it includes a power source 10, a rotating drum 21, an outer casing 22 sleeved on the outer wall of the rotating drum 21, a frame 60, and the like. The power source 10 is the power source of the present invention as the centrifugal extraction process, generally provides rotational power for the power motor, and then the power motor and the rotating drum 21 are connected by a shaft coupling. Frame 60 supports the power source 10, rotating drum 21 and outer shell 22 etc. of centrifugal extractor, is the support part of whole equipment weight, and frame 60 requires sufficient rigidity. Drum 21 is arranged such as light and heavy weir pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com