Carton cutting device and cutting method

A cutting device and carton technology, applied in welding/welding/cutting items, packaging, papermaking, etc., can solve problems such as burrs and affect product quality, and achieve the effect of improving convenience and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

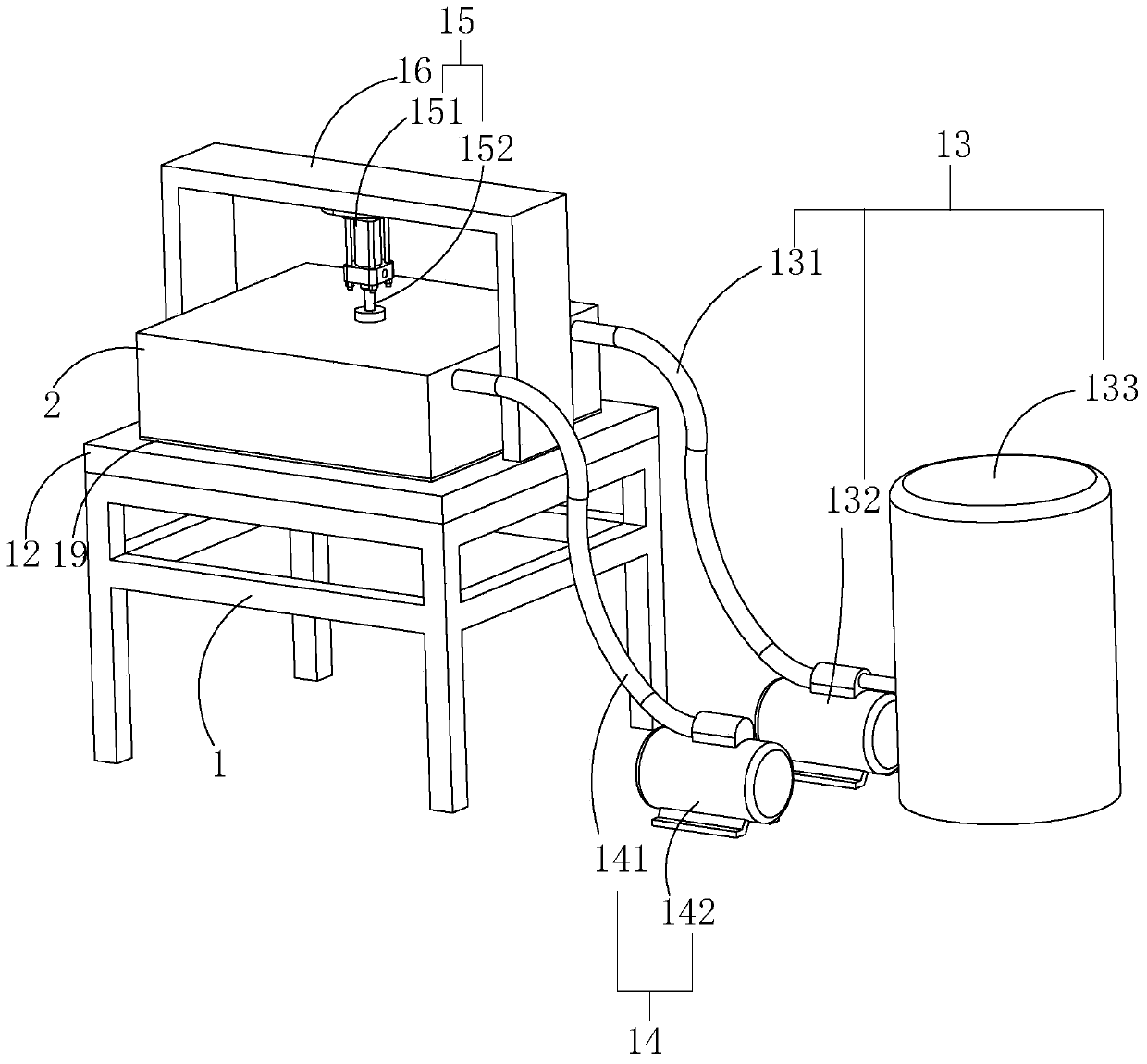

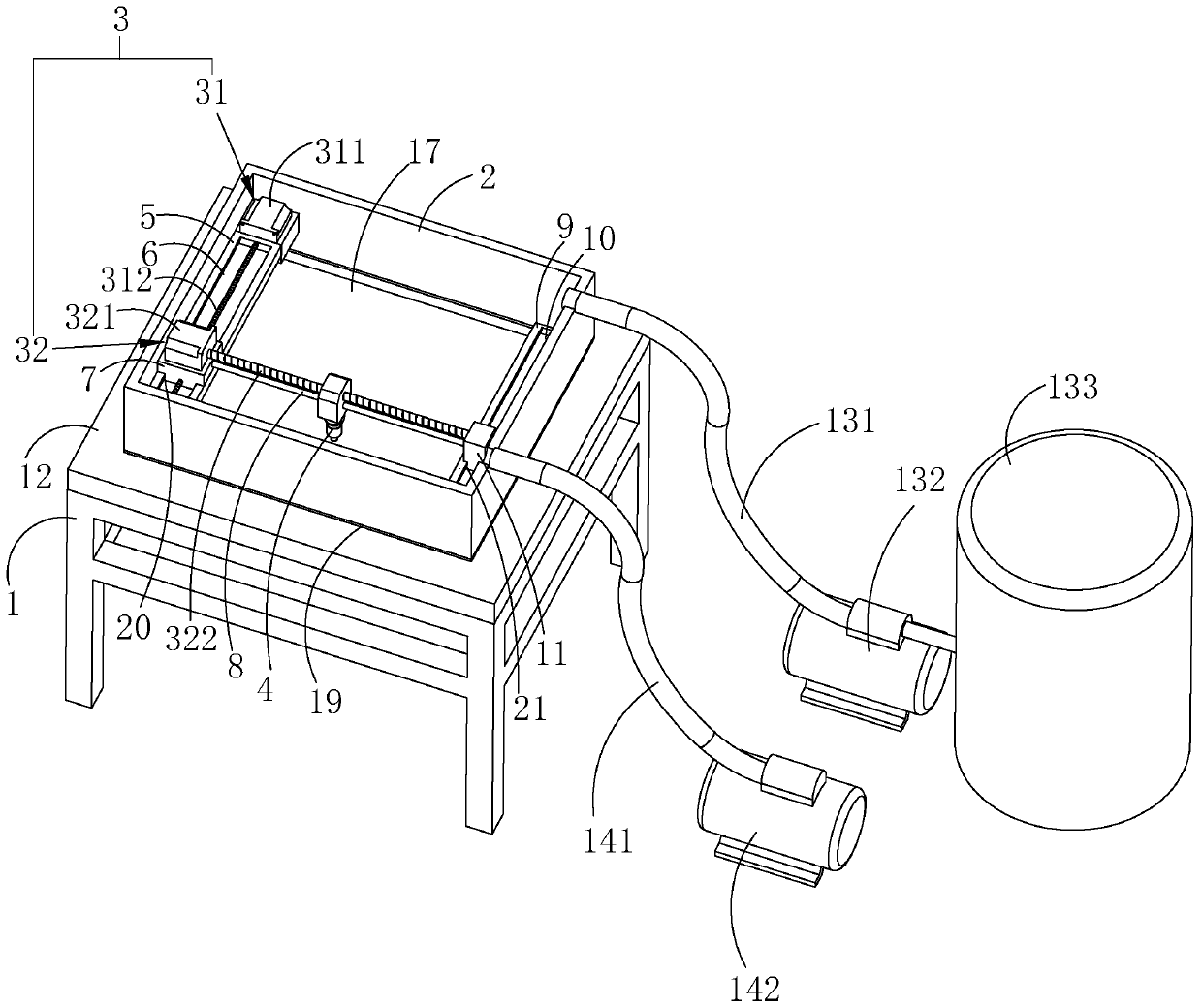

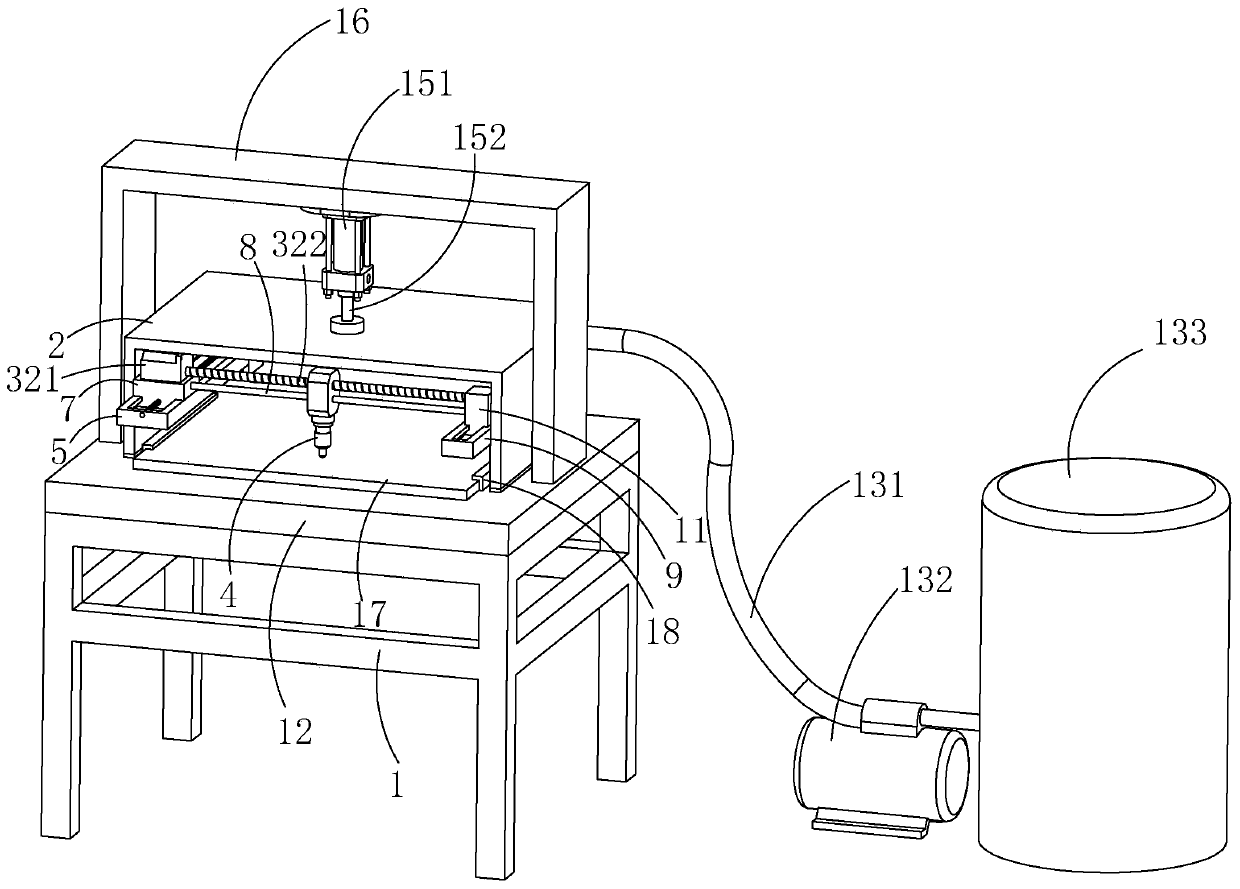

[0039] refer to figure 1 , is a kind of carton cutting device disclosed by the present invention, comprising a mounting frame 1 and a worktable 12 installed on the mounting frame 1, a sealing box 2 is arranged on the working table 12, one end of the sealing box 2 is open, and the opening of the sealing box 2 is The end faces the workbench 12, and the open end of the sealing box 2 is sealed and connected with the workbench 12. One side of the installation frame 1 is provided with a ventilation assembly 13. The ventilation assembly 13 communicates with the sealing box 2. The ventilation assembly 13 stores There are inert gases.

[0040] The ventilation assembly 13 includes a soft ventilation pipe 131, an air suction pump 132 and an air storage box 133. The air storage box 133 and the air suction pump 132 are all placed on the ground. The air tank 133 communicates with the air pump 132 . Specifically, the air outlet end of the air pump 132 communicates with the air pipe 131 , a...

Embodiment 2

[0068] refer to figure 1 , is a kind of carton cutting method disclosed in the present invention, and this method is realized by adopting the cutting device of embodiment 1, comprises the following steps:

[0069] S1: Put the cardboard 17 to be cut on the workbench 12, and start the air cylinder 15 so that the cardboard 17 is sealed and placed between the sealed box 2 and the workbench 12;

[0070] S2: Start the exhaust fan 142 to extract the original gas between the sealed box 2 and the workbench 12, and then send the gas in the gas storage box 133 into the space between the sealed box 2 and the workbench 12 through the air pump 132 cavity;

[0071] S3: start the laser component;

[0072] S4: Start the air cylinder 15 to drive the sealing box 2 to separate from the workbench 12 .

[0073] The implementation principle of this embodiment is:

[0074] By sealing the cardboard 17 between the sealed box 2 and the workbench 12, filling the sealed box 2 with helium after vacuumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com