A sulfur recovery Claus furnace oxygen-enriched blast management system and method

A sulfur recovery and management system technology, applied in combustion methods, chemical instruments and methods, sulfur compounds, etc., can solve problems such as the influence of mixing uniformity, increased operating costs, safety hazards, etc., to achieve low cost and guaranteed service life. , to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

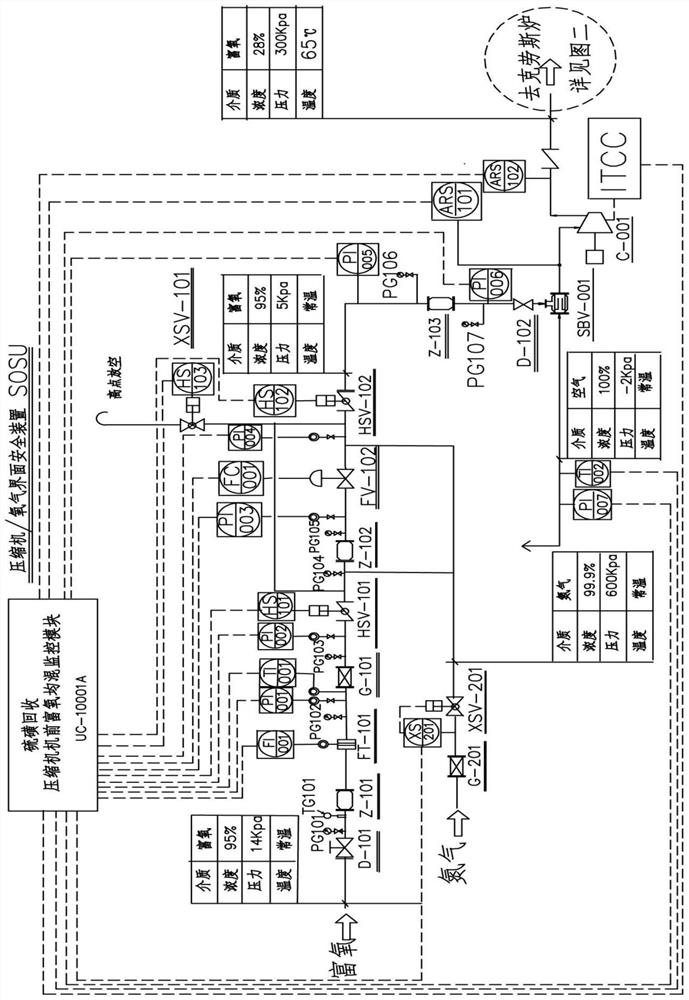

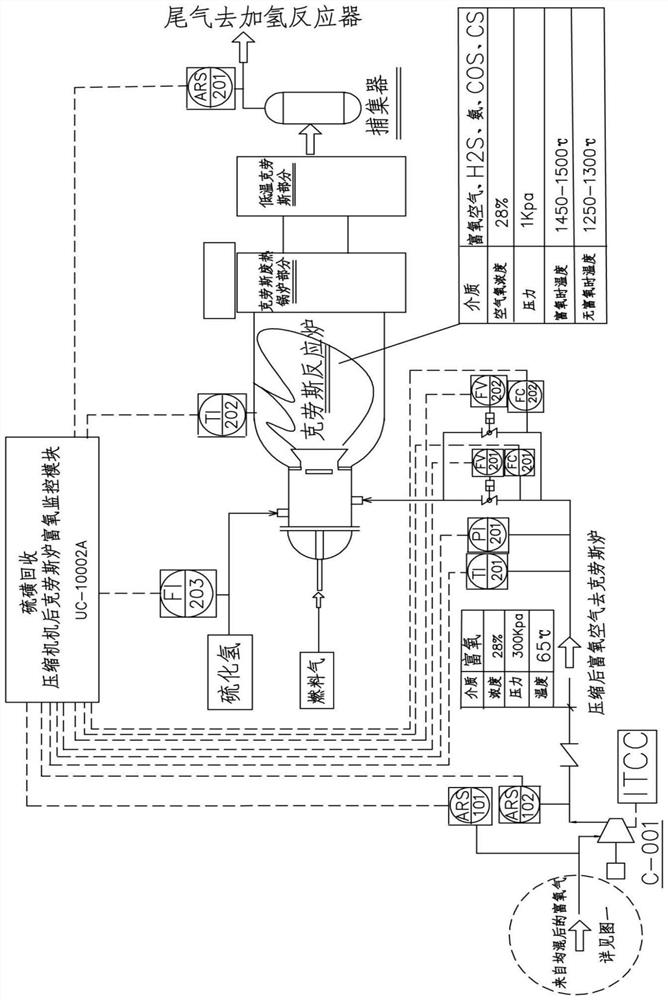

[0096] use Figure 1 to Figure 2 The system in the system carries out oxygen-enriched blasting to the Claus furnace to recover sulfur, and oxygen and air are respectively fed into the oxygen inlet pipeline and air inlet pipeline of the oxygen-enriched blast management system of the sulfur recovery Claus furnace. Under the control of the homogenization monitoring module, oxygen and air are mixed in a static mixer to obtain oxygen-enriched air;

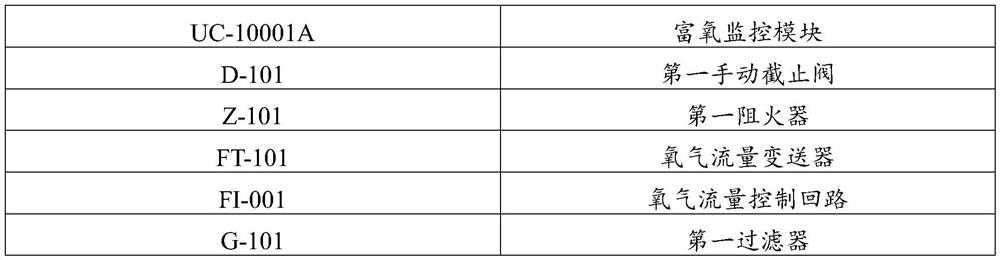

[0097] The oxygen concentration is 95%, the oxygen pressure at the inlet of the oxygen pipeline is 14KPa, the oxygen temperature is normal temperature, and the oxygen passes through the first manual stop valve, the first flame arrester, the oxygen flow transmitter, and the first filter in turn. , the first oxygen-enriched emergency shut-off valve, the second flame arrester, the oxygen-enriched flow regulating valve, the second oxygen-enriched emergency shut-off valve, the third flame arrester and the second manual shut-off valve enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com