CAS iron tailing microcrystalline glass material as well as preparation method and application thereof

A technology of glass-ceramics and iron tailings, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex heat treatment system, no attention to the compliance of heavy metal leachability, difficult operation, etc., and achieve good application Prospects, realization of harmless and resourceful utilization, effect of reducing leachability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the CAS iron tailings glass-ceramic material comprises the following steps:

[0041] 1. After drying the iron tailings in an oven at 105°C, grind and sieve them with a ceramic mortar to obtain iron tailings powder with a particle size of less than 200 μm for use;

[0042]2. Mix the iron tailings powder with the mass ratio of 10:33:38:19 with alumina, silica and calcium oxide ball mill;

[0043] 3. At room temperature, press the mixed powder into a sheet with a diameter of 30mm and a thickness of 4mm, the pressure is 20MPa, and the pressing time is 2min, so as to ensure that the powders are tightly bonded and facilitate the heat treatment reaction;

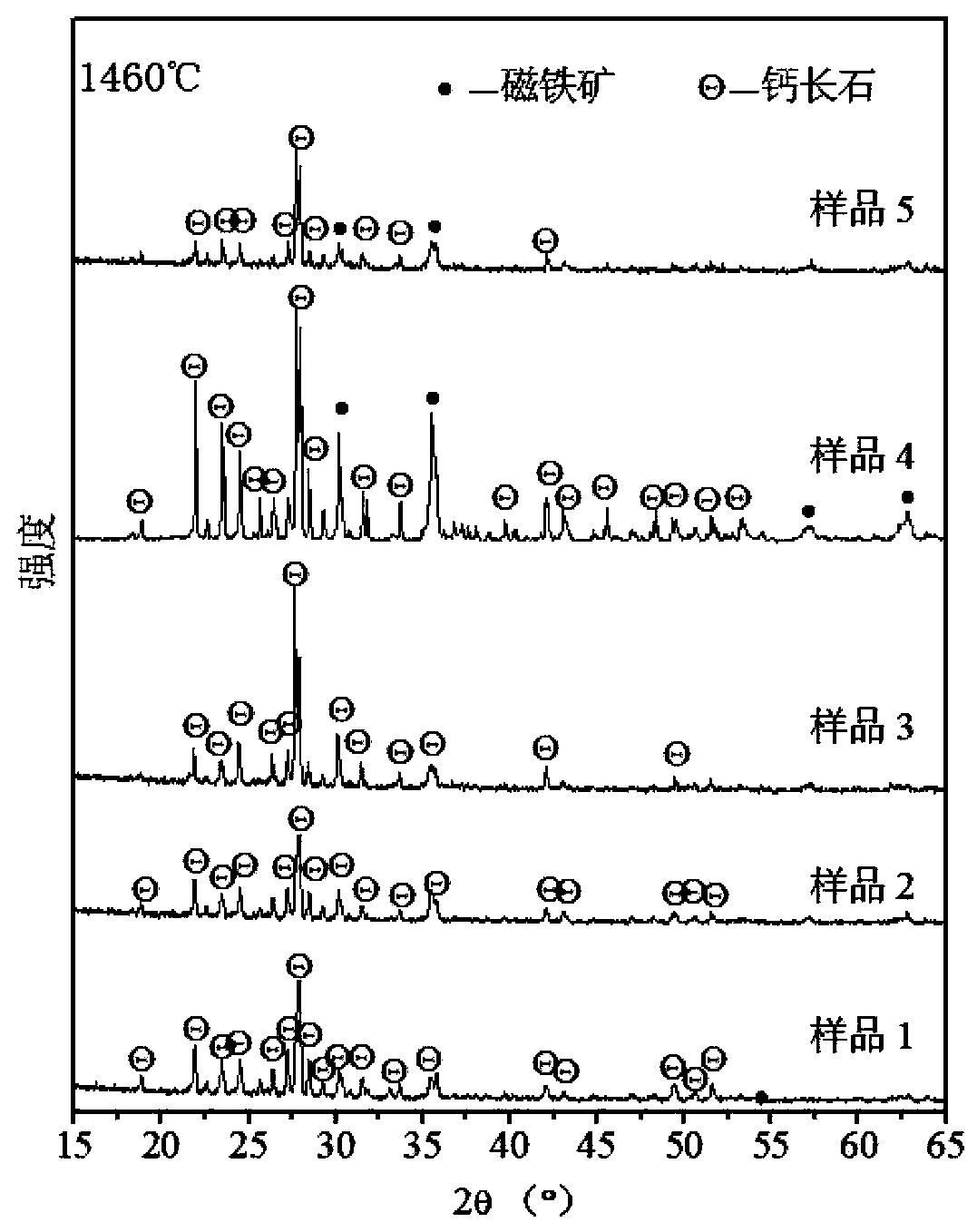

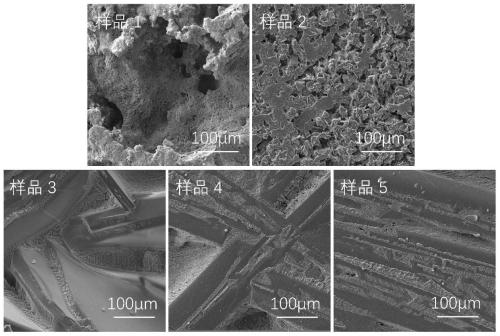

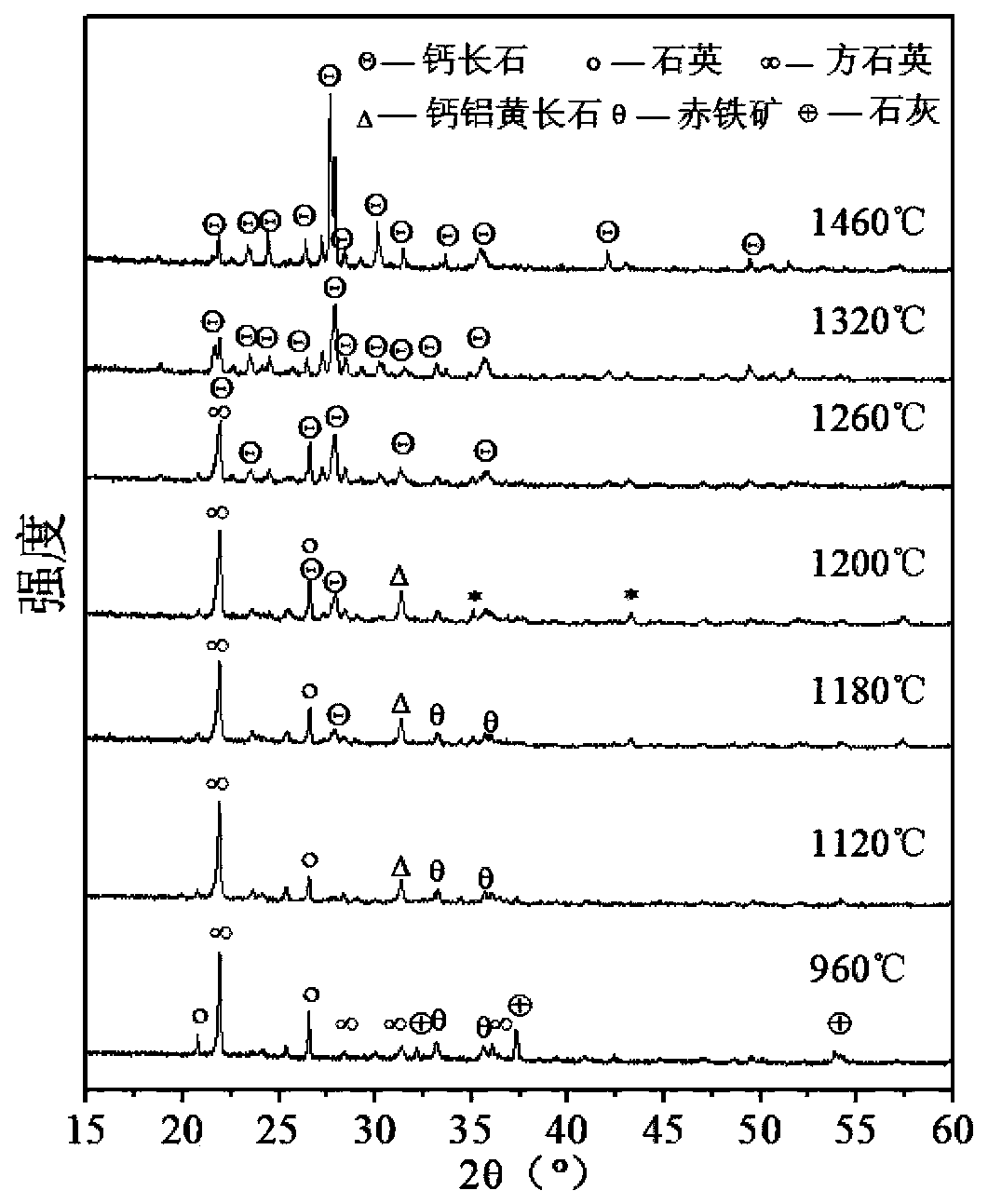

[0044] 4. Put the obtained sheet into an alumina crucible, then put the crucible into a high-temperature resistance furnace for high-temperature sintering, raise the temperature to 1460°C for sintering at a heating rate of 5°C / min, and then keep it at 1460°C for 2 hours;

[0045] 5. After the alumi...

Embodiment 2

[0047] The difference from Example 1 is that the mass ratio of iron tailings powder, alumina, silicon oxide and calcium oxide in step 2 is 14:28:32:16, and the obtained CAS iron tailings glass-ceramic material is marked For sample 2.

Embodiment 3

[0049] The difference from Example 1 is that the mass ratio of iron tailings powder, alumina, silicon oxide and calcium oxide in step 2 is 30:26:29:15, and the obtained CAS iron tailings glass-ceramic material is marked as Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com