A kind of cadmium-copper-lead polluted sediment solidification agent and its solidification method

A curing agent and lead pollution technology, which is applied in chemical instruments and methods, sludge treatment, water pollutants, etc., can solve the problems of unsatisfactory sediment fixation effect, less consideration of sediment buffer capacity, etc., to reduce leachability , Inexpensive, Accessible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The bottom mud of the irrigation canal downstream of the slag field of Guixi Smelter in Guixi City, Jiangxi Province was used as the test sample, and the composition analysis results of the bottom mud samples are shown in Table 1.

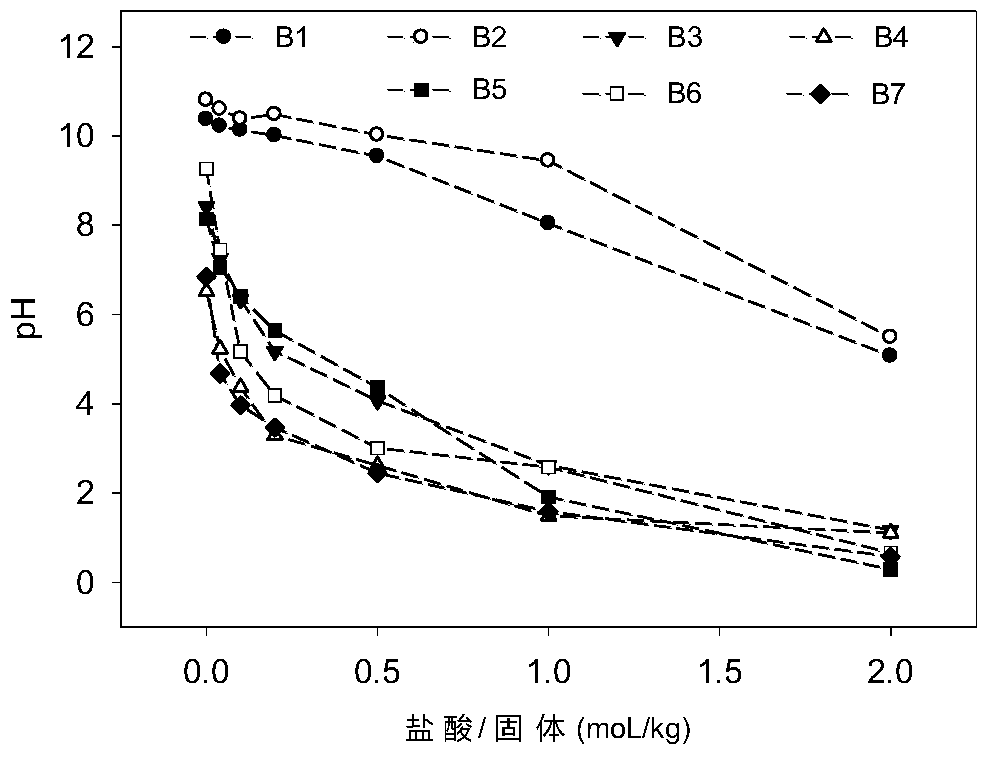

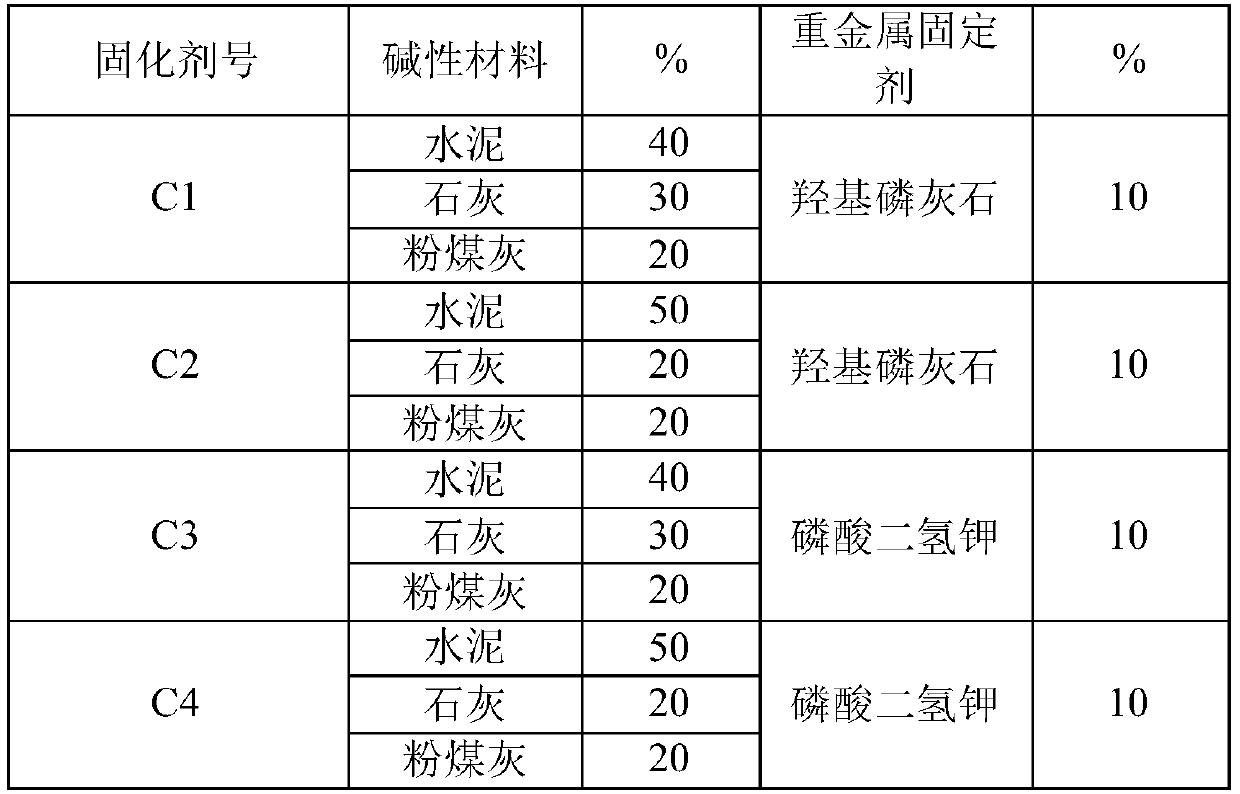

[0025] The cadmium-copper-lead-contaminated bottom mud solidifying agent of the present invention, this solidifying agent comprises alkaline material (cement, lime and fly ash, and heavy metal fixing agent (potassium dihydrogen phosphate or hydroxyapatite), formula composition sees Table 2. According to 10%, 15%, 20%, 30% and 40% of the weight of the bottom mud, add curing agent to the plastic beaker, after fully stirring, cover the plastic wrap and cultivate at a constant temperature of 25°C in an incubator. Measure the bottom mud after cultivating for 7 days pH, using solid waste leaching toxicity leaching method acetic acid buffer solution method (HJ / T300-2007) to test the leachability of heavy metals (see Table 3).

[0026] Table 1 shows...

Embodiment 2

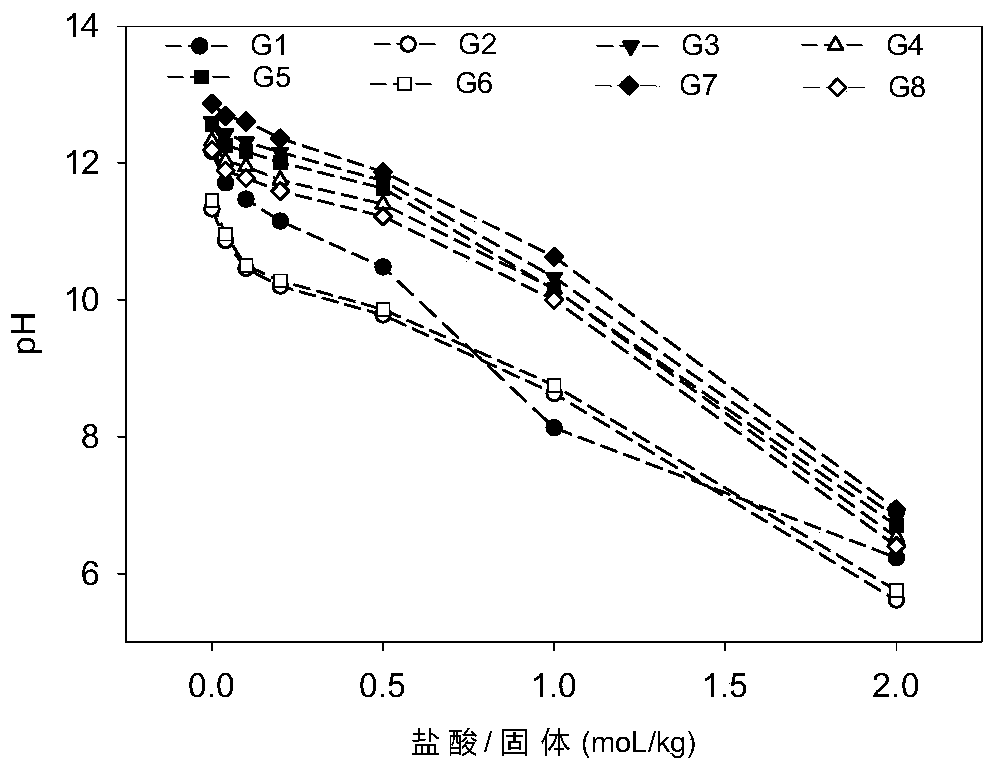

[0037] The cadmium-copper-lead-contaminated bottom mud solidifying agent of the present invention, this solidifying agent comprises alkaline material (cement, lime and fly ash), and heavy metal fixing agent (one of potassium dihydrogen phosphate and hydroxyapatite and organic macromolecular chelate Compound sodium diethyldithiocarbamate), the specific composition of the curing agent is shown in Table 4. Add cement, lime, and fly ash to the plastic beaker according to 35-43% of the weight of the bottom mud, add potassium dihydrogen phosphate, one of hydroxyapatite and sodium diethyldithiocarbamate after proper stirring, and stir well Finally, cover with plastic wrap and maintain. After cultivating for 7 days, the pH of the bottom mud was measured, and the leaching ability of heavy metals was tested by using the acetic acid buffer solution method (HJ / T300-2007) and the sulfuric acid nitric acid method (HJ-T299) of the toxic leaching method of solid waste leaching. The results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com