Heavy metal stabilization two-step method for treatment of fly ash from urban domestic refuse burning plant

A technology for municipal solid waste and fly ash incineration, which is applied in the field of solid waste treatment and disposal, can solve the problems of complex process and other problems, and achieve the effects of favorable mixing, simple process and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

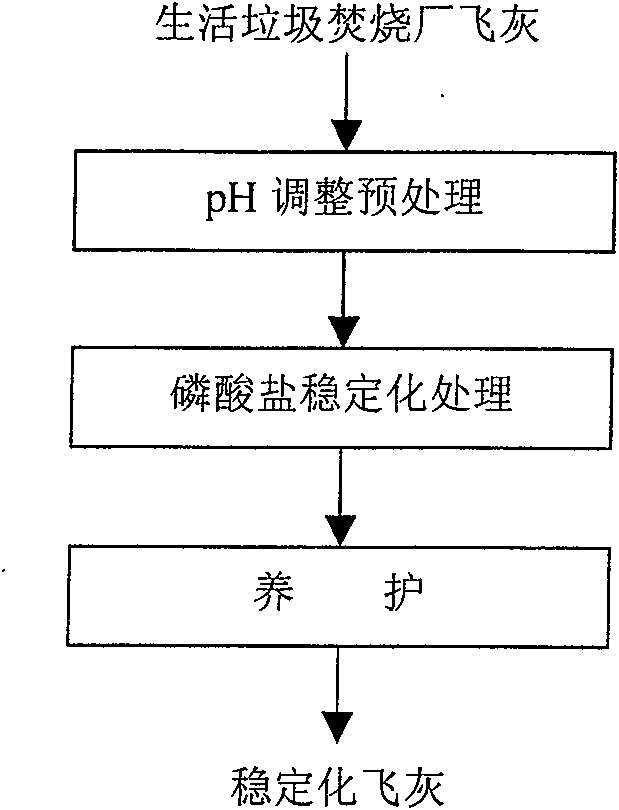

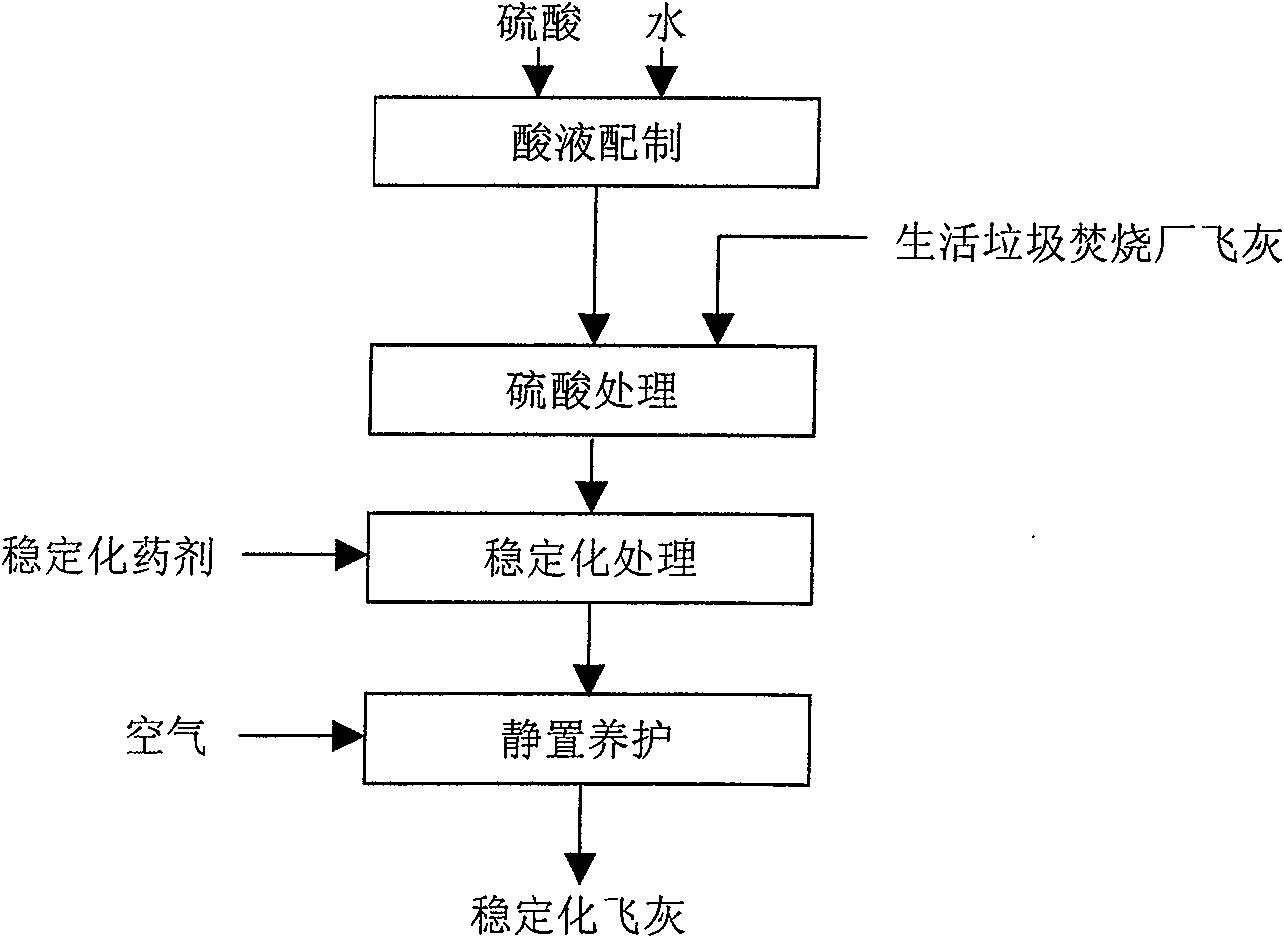

[0025] Please see attached figure 1 And attached figure 2 .

[0026] The pH was adjusted by sulfuric acid treatment, and then phosphate was added to stabilize heavy metals in the fly ash.

[0027] Step 1: add sulfuric acid to water in the acid solution mixing tank, the ratio of sulfuric acid to water, according to the mixed acid solution H + The molar concentration is controlled from 6M to 7M, and the sulfuric acid solution can be obtained after mixing evenly with slow stirring;

[0028] Step 2: Add fly ash to the stirring treatment tank, start stirring, and slowly add the above sulfuric acid solution into the tank at the same time, the mass ratio of the accumulatively added acid solution to fly ash is controlled to be 1:3.5; after the sulfuric acid solution and fly ash are stirred evenly , and then slowly add the stabilizing agent phosphate into the tank while stirring; the stabilizing agent should be ground and passed through a 60-mesh sieve before use, and the active in...

Embodiment 2

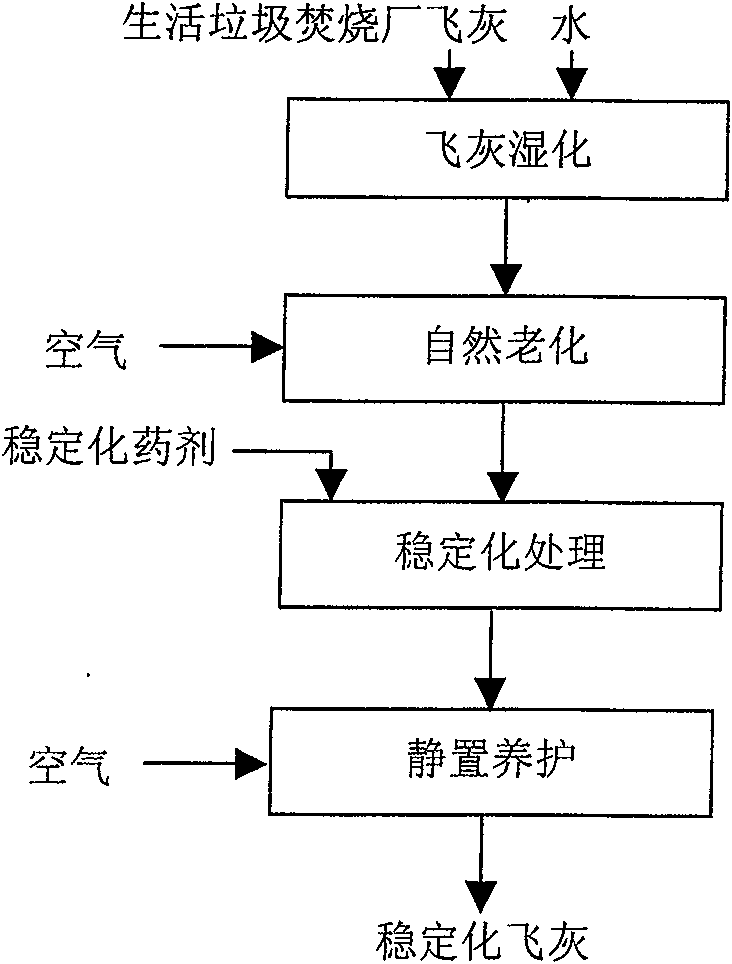

[0034] Please see attached figure 1 And attached image 3 .

[0035] The pH was adjusted by natural aging method and phosphate was added to stabilize heavy metals in fly ash.

[0036] Step 1: Add fly ash to the pretreatment tank, start stirring, and slowly add water into the tank at the same time, the mass ratio of the accumulatively added water to fly ash is controlled to be 1:5; after the water and fly ash are stirred evenly, wet fly ash;

[0037] Step 2: Discharge the humidified fly ash from the pretreatment tank, evenly spread (thickness 0.2 to 0.3m) in the air circulation space, and age for 2 days. During this period, turn the pile once every 8 hours to obtain natural aging fly ash;

[0038] Step 3: Add the natural aging fly ash into the mixing treatment tank, start the stirring, and at the same time slowly add the stabilizing agent into the tank while stirring; the stabilizing agent should be ground and passed through a 60-mesh sieve before use, and the active ingredi...

Embodiment 3

[0044] Please see attached figure 1 And attached Figure 4 .

[0045] The pH was adjusted by forced aging method, and then phosphate was added to stabilize heavy metals in fly ash.

[0046] Step 1: same as step 1 of embodiment 2;

[0047] Step 2: Discharge the humidified fly ash from the pretreatment tank, evenly spread (thickness 0.1 to 0.2m) in the forced aging room, and age for 8 hours to obtain the forced aging fly ash; the forced aging room is an airtight space, set The gas port introduces flue gas from the chimney of the incineration plant through the induced draft fan, flows evenly through the forced aging room, and then returns to the chimney of the incineration plant to be discharged; the volume of flue gas flowing through the forced aging room per hour is 6 to 8 times the volume of the aging room, That is, the flue gas exchange rate in the aging chamber is 6 to 8 times / hour.

[0048] Step 3: Except that the natural aging fly ash is replaced by forced aging fly as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com