Topdressing-free rice special formula fertilizer and preparation method and use method thereof

A formula fertilizer and rice technology, applied in application, phosphate fertilizer, fertilization equipment, etc., can solve problems such as difficulty in mastering technical points, unscientific nutrient distribution ratio, improper fertilizer operation, etc., to suppress the loss of nitrification and denitrification, and reduce fertilization Labor intensity, the effect of fertilizing the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

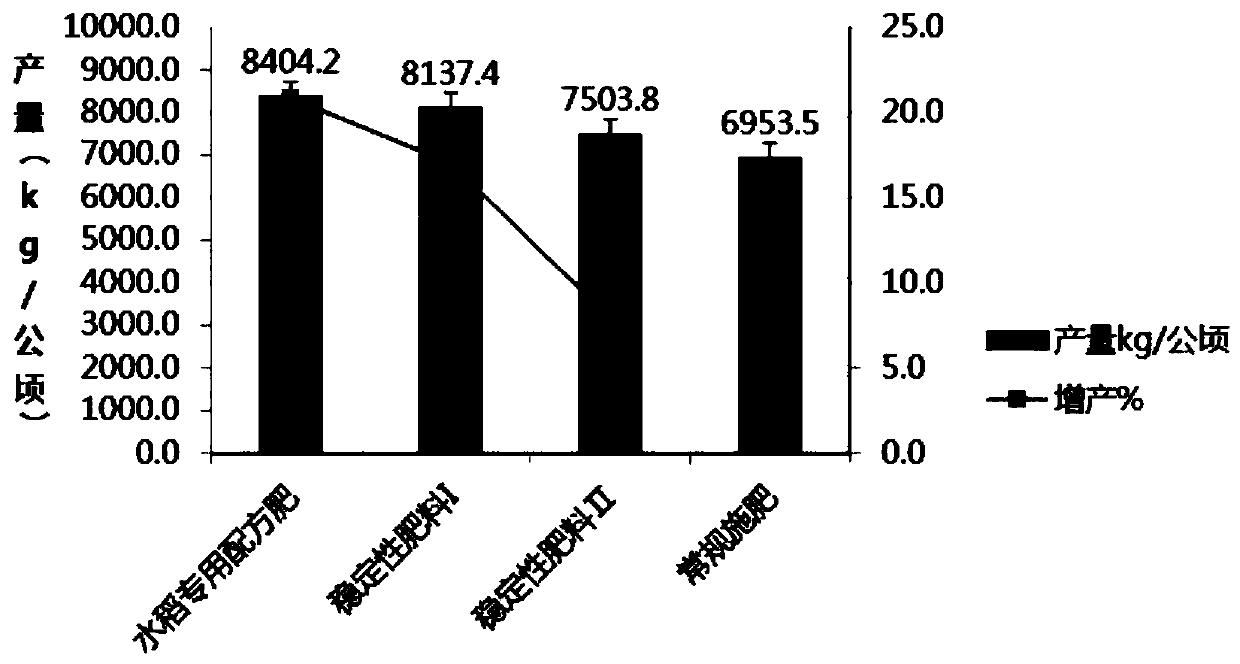

Examples

Embodiment 1

[0031] 1) urea and potassium sulfate with potassium oxide content of 50% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0032] The urea is urea A with a nitrogen content of 46.4%, resin-coated urea B with a release period of 30-40 days, resin-coated urea C with a release period of 60-70 days, and resin-coated urea D with a release period of 100-120 days The mixture, wherein the mass ratio of A, B, C, and D is 10:3:1:0.5, and the nitrogen content of B, C, and D is 44%.

[0033] The potassium sulfate comprises 30% by mass of resin-coated potassium sulfate with a release period of 70-90 days.

[0034] 1) urea and potassium sulfate with potassium oxide content of 50% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0035] 2) Select N-P 2 o 5 -K 2 O ratio is 3.52-41.95-1.4 industrial raw materials as phosphorus raw materials;

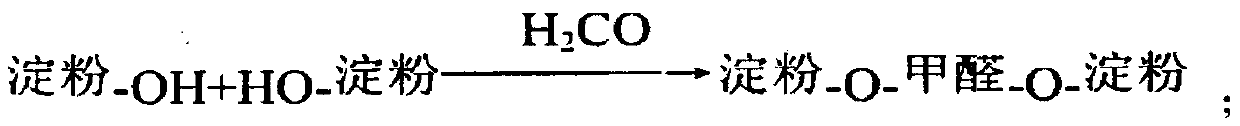

[0036] 3) Prepare granulation binder mother...

Embodiment 2

[0046] 1) urea and potassium sulfate with a potassium oxide content of 60% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0047] The urea is urea A with a nitrogen content of 46.4%, resin-coated urea B with a release period of 30-40 days, resin-coated urea C with a release period of 60-70 days, and resin-coated urea D with a release period of 100-120 days The mixture, wherein the mass ratio of A, B, C, and D is 10:3:1.5:0.3, and the nitrogen content of B, C, and D is 45%.

[0048] The potassium sulfate comprises 35% by mass of resin-coated potassium sulfate with a release period of 70-90 days.

[0049] 1) urea with a nitrogen content of 46.4% and potassium sulfate with a potassium oxide content of 50% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0050] 2) Select N-P 2 o 5 -K 2 O ratio is 3.52-41.95-1.4 industrial raw materials as phosphorus raw materials;

[005...

Embodiment 3

[0061] 1) urea and potassium sulfate with potassium oxide content of 50% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0062] The urea is urea A with a nitrogen content of 46.4%, resin-coated urea B with a release period of 30-40 days, resin-coated urea C with a release period of 60-70 days, and resin-coated urea D with a release period of 100-120 days The mixture, wherein the mass ratio of A, B, C, and D is 10:3:1.2:0.4, and the nitrogen content of B, C, and D is 44%.

[0063] The potassium sulfate comprises 40% by mass of resin-coated potassium sulfate with a release period of 70-90 days.

[0064] 1) urea with a nitrogen content of 46.4% and potassium sulfate with a potassium oxide content of 50% are pulverized by a micro pulverizer and passed through an 80-mesh sieve, and bagged for later use;

[0065] 2) Select N-P 2 o 5 -K 2 O ratio is 3.52-41.95-1.4 industrial raw materials as phosphorus raw materials;

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com