Whole-course wheat mechanical planting method

A whole-process mechanization and planting method technology, applied in the field of wheat planting mechanization, can solve the problems of unmatched four furrows, inconsistent depth, uneven seedling emergence, etc., and achieve the effect of reducing labor intensity, uniform sowing, and neat seedling emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

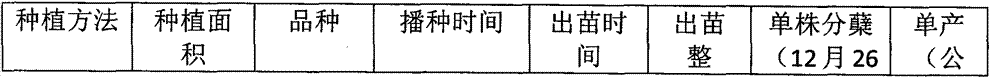

Embodiment 1

[0024] A whole-process mechanized planting method for wheat mainly comprises the following steps:

[0025] Step 1: Select good varieties and sow seeds in the right amount at the right time

[0026] Select the high-quality weak-gluten wheat variety "Emai 27" to achieve "three suitable" sowing, that is, suitable period, appropriate amount, and appropriate moisture content; the appropriate period is October 29, and the appropriate amount is 11 per acre. kg, the appropriate moisture content is that the soil water content reaches 75% of the field water holding capacity when sowing, and the pre-sowing medicament seed dressing process is mixed with 11 kg of wheat seeds with 8 grams of Gaoqiao+50 milliliters of Yongye Biotin, and the seed dressing process is followed by ready to use;

[0027] Step 2: Choose the right model to improve the quality of sowing

[0028] Choose a suitable model that integrates the rotary tiller and the seeder, the seeder is 2B×YF-4 / 12, the supporting power...

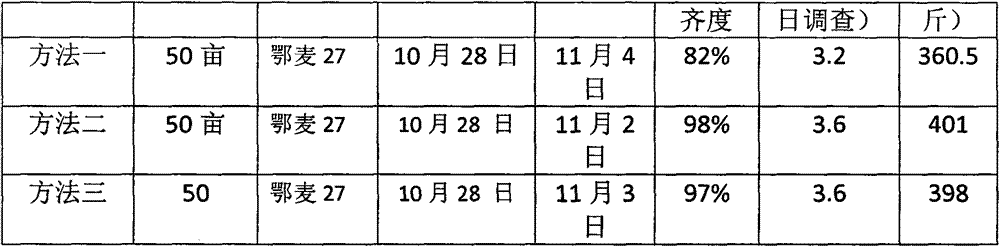

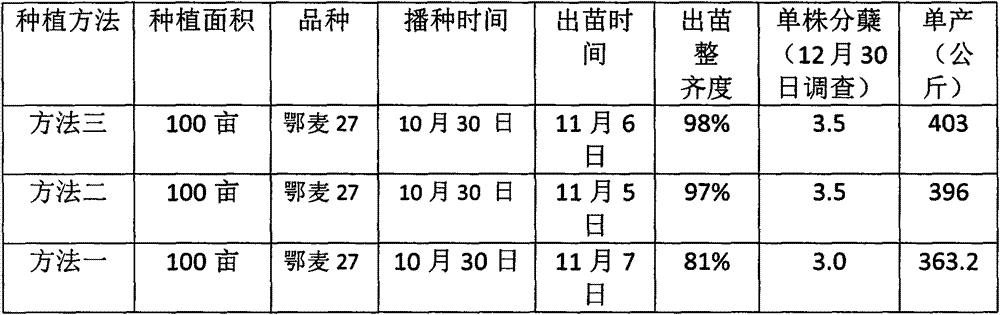

Embodiment 2

[0041] A whole-process mechanized planting method for wheat mainly comprises the following steps:

[0042] Step 1: Select good varieties and sow seeds in the right amount at the right time

[0043] Select the high-quality weak-gluten wheat variety "Xiangmai 25" to achieve "three suitable" sowing, that is, suitable period, appropriate amount, and appropriate moisture content; the appropriate period is November 3, and the appropriate amount is 10 per acre. kg, the appropriate moisture content is that the soil water content reaches 80% of the field water holding capacity when sowing, and the seed dressing treatment is performed with medicaments before sowing; add Yongye Biovitamin with 15% triadimefon wettable powder, 23 grams of triadimefon + Yongye Mix 45ml of biotin with 10kg of wheat seeds, the seeds are treated, and can be used as needed.

[0044] Step 2: Choose the right model to improve the quality of sowing

[0045] Choose the seeder 2BXYF-4 / 12, which integrates the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com