Preparation method of mivacurium chloride and injection thereof

A technology of mivacurium chloride and injection, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve problems such as stability and safety issues that have not been properly resolved , to achieve the effect of good long-term storage stability, less impurities, and less impurity components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

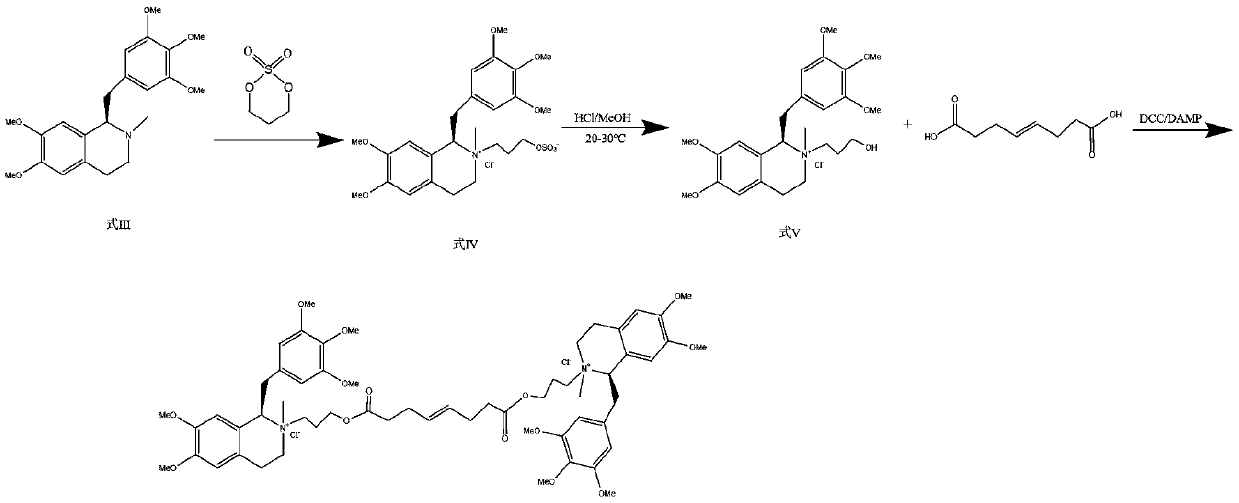

[0052] A method for synthesizing micuronium chloride, including the following steps:

[0053]

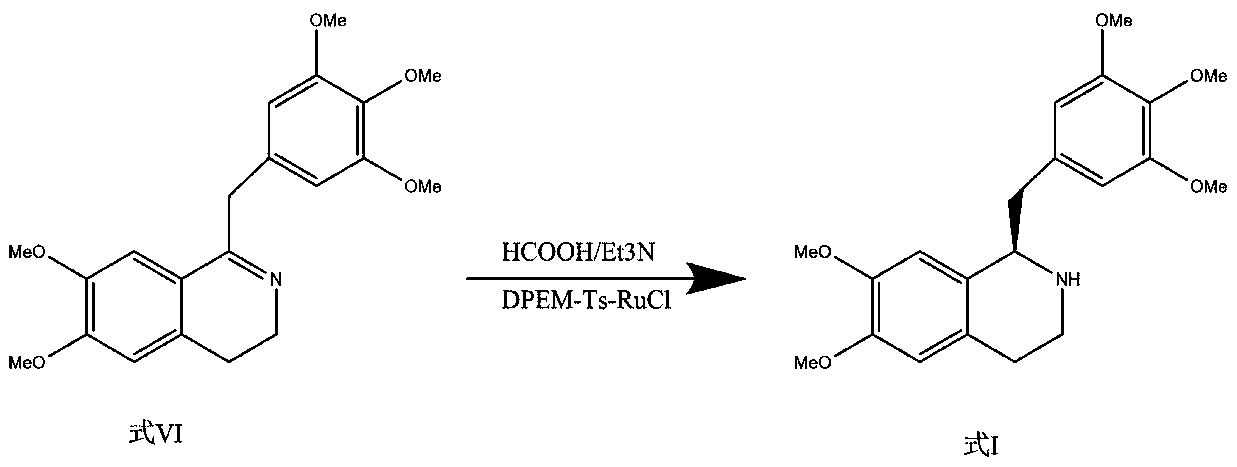

[0054] Step 1: Asymmetric catalytic reduction

[0055] The crude product (100g) of the compound of formula VI was dissolved in tetrahydrofuran (1000ml), degassed ultrasonically and replaced with nitrogen for 5 minutes, added with the metal chiral catalyst RuCl-Ts-DPEN (2500mg), formic acid-triethylamine (V / V= 5:3, 15mL), react at 15°C for 2.5 hours. Add saturated NaHCO 3 The aqueous solution (3000 mL) was quenched, and extracted with ethyl acetate (2000 mL) for three consecutive times, and the extracts were combined; the extract was washed twice with saturated brine (500 mL) and dried to obtain the compound of formula I of type R (91.9 g).

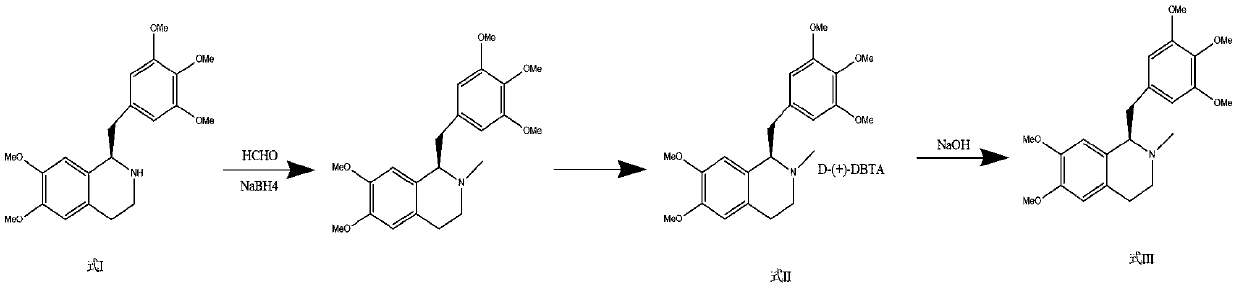

[0056] Step 2: Methylation and purification of amine

[0057] In 1500 ml of ethyl acetate, the compound of formula I (100 g), sodium borohydride (120 g), and 1200 ml of 37% formaldehyde solution were added, and refluxed until the reaction was complete....

Embodiment 2

[0063] A method for synthesizing micuronium chloride, including the following steps:

[0064] Step 1: Asymmetric catalytic reduction

[0065] The crude product (100g) of the compound of formula VI was dissolved in dichloromethane (1000ml), degassed ultrasonically, replaced with nitrogen for 5 minutes, and added with the metal chiral catalyst RuCl-Ts-DPEN (2200mg), formic acid-triethylamine (V / V=9:4, 20mL), reacted at 0°C for 7.5 hours. Add saturated NaHCO 3 The aqueous solution (3000 mL) was quenched, and extracted with dichloromethane (2000 mL) for 3 consecutive times, and the extracts were combined; the extract was washed twice with saturated brine (500 mL) and dried to obtain the R-type compound of formula I (90.3 g).

[0066] Step 2: Methylation and purification of amine

[0067] Add formula I compound (100g) and sodium borohydride (95g) to 1500ml of tetrahydrofuran, then add 1400ml of 30% formaldehyde solution, and reflux until the reaction is complete. After cooling to room t...

Embodiment 3

[0073] A method for synthesizing micuronium chloride, including the following steps:

[0074] Step 1: Asymmetric catalytic reduction

[0075] The crude product (100g) of the compound of formula VI was dissolved in methyl tert-butyl ether (1000ml), degassed ultrasonically and replaced with argon for 5 minutes, added with the metal chiral catalyst RuCl-Ts-DPEN (2000mg), formic acid-triethyl Amine (V / V=3:2, 18mL), reacted at 4°C for 6.5 hours. Add saturated NaHCO 3 The aqueous solution (2500mL) was quenched, and the extracts were continuously extracted with methyl tert-butyl ether (2000ml) for 3 times, and the extracts were combined; the extracts were washed twice with saturated brine (500ml) and dried to obtain the R-type compound of formula I (91.1g) ).

[0076] Step 2: Methylation and purification of amine

[0077] Add the compound of formula I (100g) and sodium borohydride (90g) to 1500ml of dichloromethane, and then add 800ml of 40% formaldehyde solution, and reflux until the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com