Boron-containing organic compound and application thereof on organic electroluminescent devices

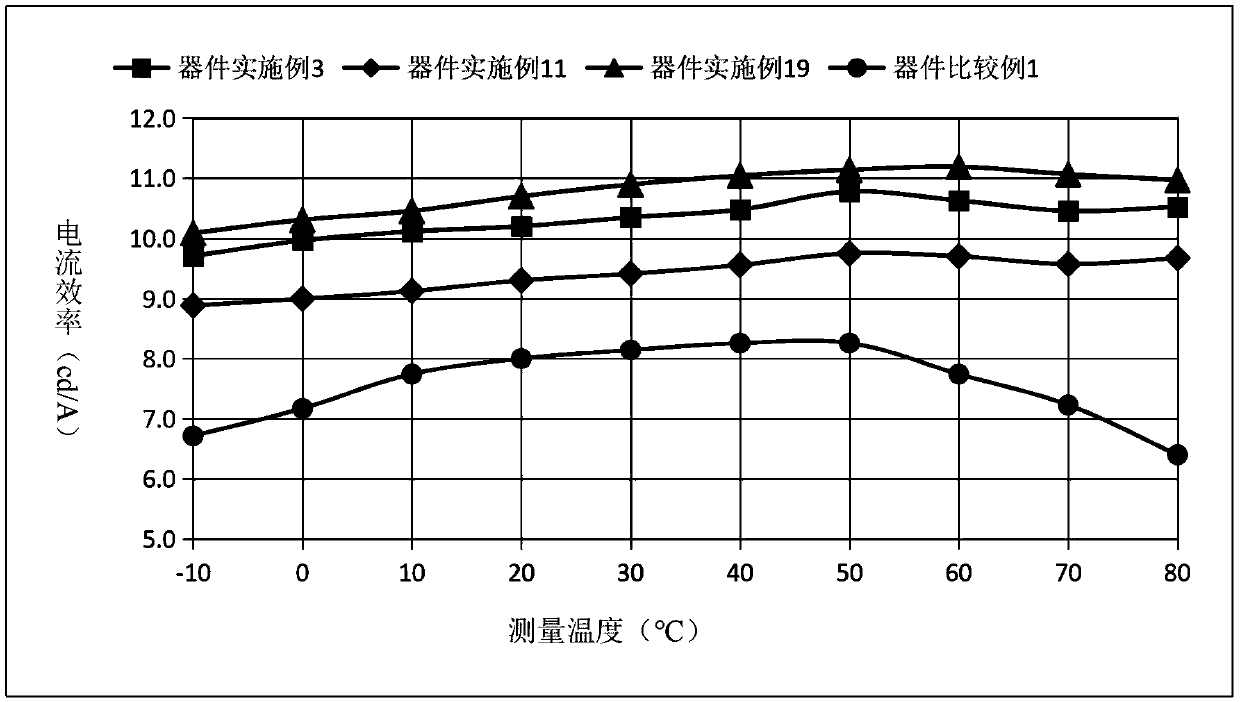

An organic compound, unsubstituted technology, applied in the field of semiconductors, can solve the problems of low state radiative transition rate, difficult high exciton utilization rate and high fluorescence radiative efficiency, efficiency roll-off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

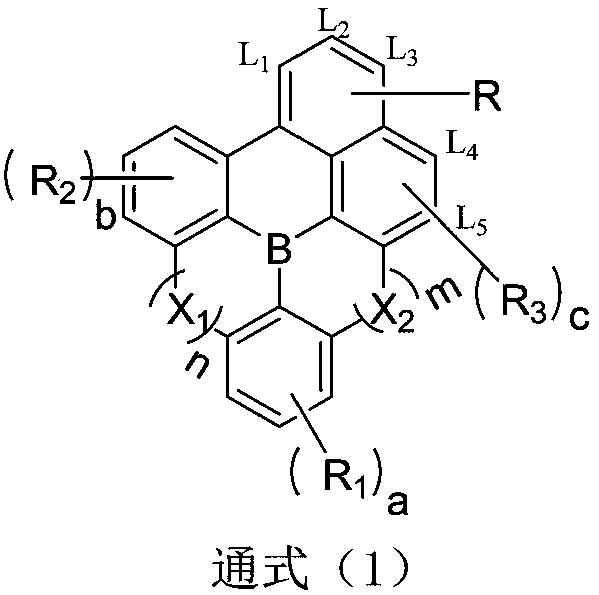

Method used

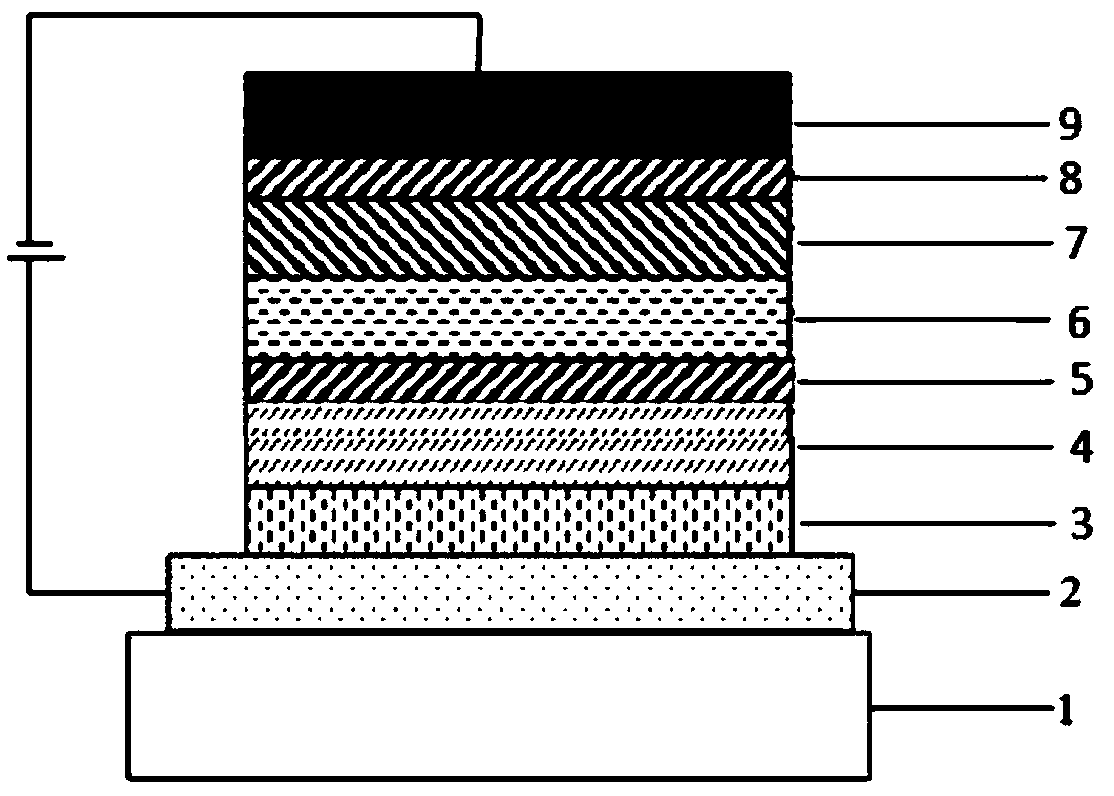

Image

Examples

Embodiment 1

[0083] Embodiment 1: the synthesis of compound 3:

[0084]

[0085] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol intermediate P1, 0.01mol raw material E1, 0.01mol BBr 3 , 150ml THF, stirred at 50°C for 16 hours, cooled to room temperature, added methanol, stirred and reacted for 1 hour, sampled on the plate, and the reaction was complete; cooled to room temperature, filtered, the filtrate was rotary evaporated to no fraction, passed through a neutral silica gel column, and obtained The target product has an HPLC purity of 99.76% and a yield of 76.1%. Elemental analysis structure (molecular formula C 38 h 41 B): Theoretical value: C, 89.75; H, 8.13; B, 2.13; Test value C, 89.74; H, 8.12; B, 2.14. HPLC-MS: The molecular weight of the material is 508.33, and the measured molecular weight is 508.56.

Embodiment 2

[0086] Embodiment 2: the synthesis of compound 12:

[0087]

[0088] Prepare by the synthetic method of compound 3 in embodiment 1, difference is to replace intermediate P1 with intermediate P2; Elemental analysis structure (molecular formula C 39 h 39 BO): theoretical value: C, 87.63; H, 7.35; B, 2.02; 0, 2.99; test value C, 87.62; H, 7.34; B, 2.03; HPLC-MS: The molecular weight of the material is 534.31, and the measured molecular weight is 534.55.

Embodiment 3

[0089] Embodiment 3: the synthesis of compound 18:

[0090]

[0091] Prepare by the synthetic method of compound 3 in embodiment 1, difference is to replace intermediate P1 with intermediate P3; Elemental analysis structure (molecular formula C 45 h 44 BN): theoretical value: C, 88.65; H, 7.27; B, 1.77; 0, 2.30; test value C, 88.64; H, 7.28; B, 1.78; HPLC-MS: The molecular weight of the material is 609.36, and the measured molecular weight is 609.66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com