Double-liquid type liquid rubber for liquid silica gel roller and preparation method thereof

A technology of liquid silica gel and liquid rubber, which is applied in the field of liquid rubber, can solve problems such as inconsistent local performance, uneven solute flow velocity, and influence on the mechanical properties of liquid rubber, and achieve excellent mechanical properties, easy infiltration and dispersion, and improved mechanical properties and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

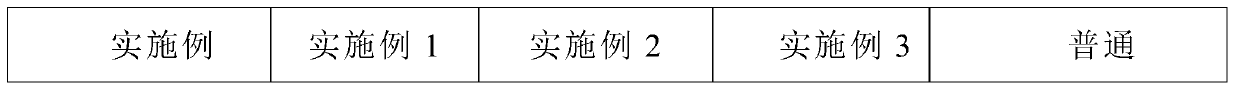

Examples

Embodiment 1

[0042] Take the first coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 4, heat up to 65 ° C for pre-hydrolysis for 30 min to obtain solution A, take another absolute ethanol, add silica, and stir for 20 min to prepare a solution B, mix solution A and solution B, heat up to 60°C and reflux for 4h, then cool to room temperature, filter the obtained product, and dry at 75°C for 1h to prepare raw material A;

[0043] Take the second coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 3, heat up to 60 ° C for pre-hydrolysis for 30 minutes to obtain solution C, take another absolute ethanol, add alumina powder, and stir for 20 minutes to prepare a solution D, mix solution C and solution D, heat up to 70°C and reflux for 3h, then cool to room temperature, filter the obtained product, and dry at 80°C for 1h to prepare raw material B;

[0044] Take 21% of raw material ...

Embodiment 2

[0050] Take the first coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 4.5, heat up to 70 ° C for pre-hydrolysis for 45 minutes to obtain solution A, take another absolute ethanol, add silica, and stir for 25 minutes to obtain a solution B. Mix solution A and solution B, heat up to 68°C and stir under reflux for 4.5h, then cool to room temperature, filter the obtained product, and dry at 80°C for 1-2h to prepare raw material A;

[0051] Take the second coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 3.5, heat up to 65 ° C for pre-hydrolysis for 45 minutes to obtain solution C, take another absolute ethanol, add alumina powder, and stir for 25 minutes to obtain a solution D, mix solution C and solution D, heat up to 75°C and reflux for 4h, then cool to room temperature, filter the obtained product, and dry at 85°C for 1.5h to prepare raw material B;

[0052...

Embodiment 3

[0058] Take the first coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 5, heat up to 75 ° C for pre-hydrolysis for 60 min to obtain solution A, take another absolute ethanol, add silica, and stir for 30 min to prepare a solution B. Mix solution A and solution B, heat up to 75°C and stir under reflux for 5h, then cool to room temperature, filter the obtained product, and dry at 85°C for 2h to prepare raw material A;

[0059] Take the second coupling agent and add absolute ethanol, then add hydrochloric acid to adjust the pH value of the solution to 3-4, heat up to 70 ° C for pre-hydrolysis for 60 min to obtain solution C, take another absolute ethanol, add alumina powder, stir for 30 min, prepare Solution D was obtained, solution C was mixed with solution D, the temperature was raised to 80°C and refluxed and stirred for 5h, then cooled to room temperature, the obtained product was filtered, and dried at 90°C for 2h to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com