Vanillin-based imine structure-containing degradable polyurethane elastomer and preparation method thereof

A polyurethane elastomer, aldehyde-containing imine technology, applied in the field of degradable polyurethane elastomer based on vanillin-containing imine structure and its preparation, can solve the problems of large consumption of petroleum resources, difficult degradation of synthetic polyurethane, etc., and achieve simple reaction process Low toxicity, high degradation rate, improved thermal stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention first provides a method of preparing an imine-containing degradable polyurethane elastomer, comprising the steps of:

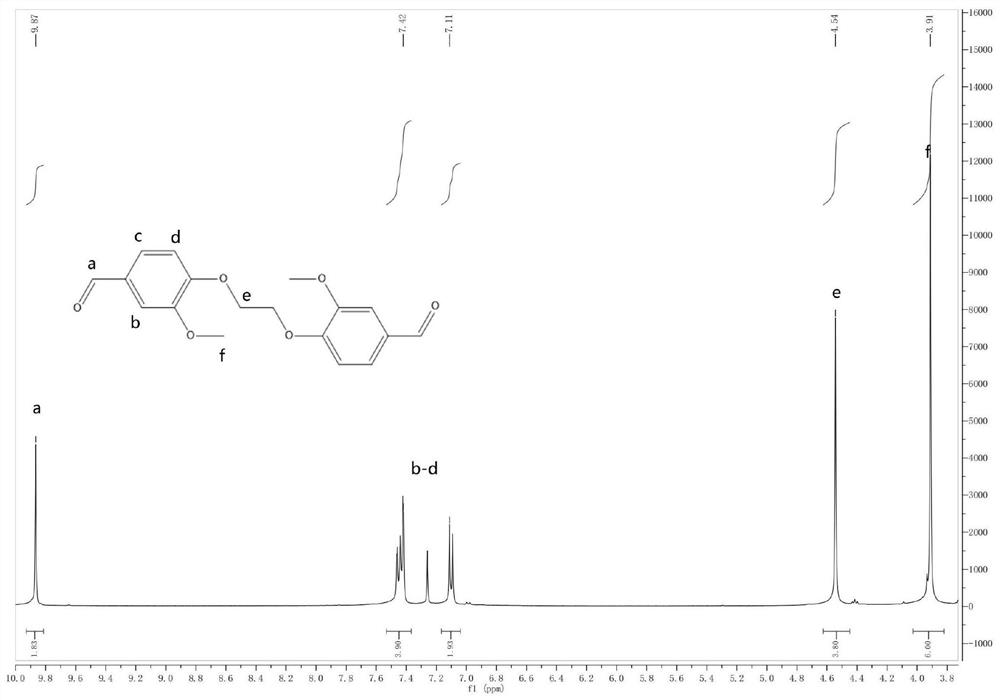

[0034] Step 1: The vanilla and hydroxide are dissolved in ethanol, then 1,2-dibromoethane and phase transfer catalyst iodide reactions, the steps of the chalcal dehydrate: 1,2-dibromoethane: Sodium hydroxide: the molar ratio of potassium iodide is 2: 1: 2: 0.05. The reaction temperature is preferably from 60 to 80 ° C, and the reaction time is preferably 24-48 h. After the reaction is completed, the dried dried to obtain a polyurethane chain extender precursor (VV); the vapildehyde and 1,2-dibromoethane The molar ratio is preferably 2: 1; the reaction process is as follows:

[0035]

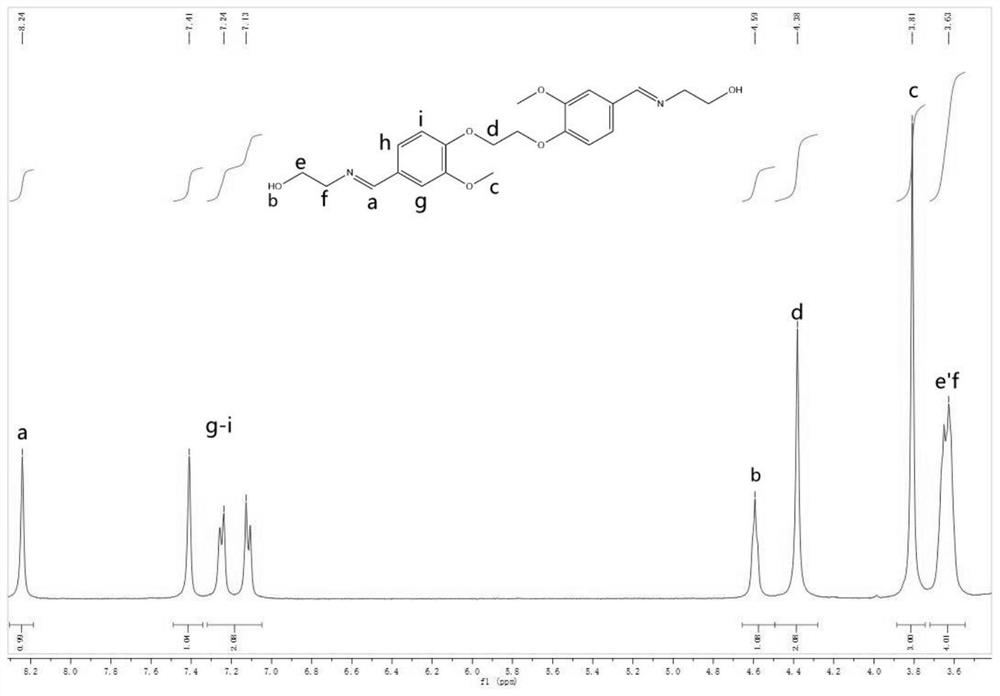

[0036] Step 2: The polyurethane chain extender precursor (VV) and a ethanolamine mixed by the step, the reaction temperature is preferably from 50 to 70 ° C, and the reaction time is preferably 3-5 h, and the product is cooled to room temperature after ...

Embodiment 1

[0041] (1) Weigh 24.6 g of vapildehyde and 7.12 g of sodium hydroxide addition in a flask containing 200 ml of ethanol, then weighing the phase transfer catalyst 1.35 g of potassium iodide and 7 ml of 1,2-dibromoethane added to the flask, at 60 The reaction was reacted under the conditions of ° C for 24 h to obtain a sterior compound (VV).

[0042] (2) Take ethanolamine 12.2 g and 33 g of adel compound (VV), placed in a 250 mL flask, then 150 ml of ethanol, then react at a temperature of 60 ° C for 4 h, filtered, washed 5 times with deionized water, obtained The product is dry after drying.

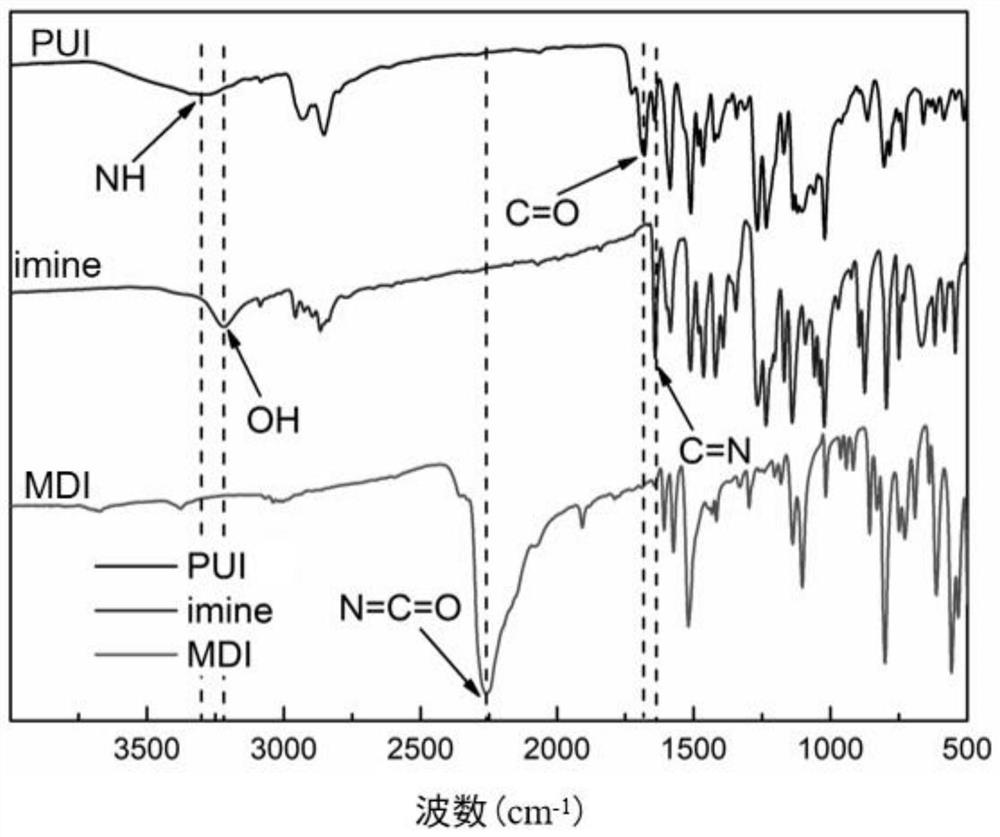

[0043] (3) Putting the product 3.328g from step (2) into a 100 mL flask to add polytetrahydrofuran toionate 4g, MDI isocyanate 3g, dibutyl tin ketaraenate, reacting at a temperature of 40 ° C for 3 h, pour into the mold into the mold The product was obtained after drying.

[0044] Example 1 Nuclear magnetic resonance spectrum pattern having an imine-containing degrading polyurethane elastomer...

Embodiment 2

[0047] (1) Weigh 24.6 g of vapildehyde and 7.12 g of sodium hydroxide addition in a flask containing 200 ml of ethanol, then weighing the phase transfer catalyst 1.35 g of potassium iodide and 7 ml of 1,2-dibromoethane were added to the flask. The reaction was reacted at 70 ° C for 24 h to obtain a sterior compound (VV).

[0048] (2) Take ethanolamine 12.2 g and 33 g of adel compound (VV), placed in a 250 mL flask, then 150 ml of ethanol, then react at a temperature of 60 ° C for 4 h, filtered, washed 5 times with deionized water, obtained The product is dry after drying.

[0049] (3) Putting the product 3.328g from step (2) into a 100 mL flask to add polytetrahydrofuran toionate 4g, MDI isocyanate 3g, dibutyl tin ketaraenate, reacting at a temperature of 40 ° C for 3 h, pour into the mold into the mold The product was obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com