Polyimide film with synergistic cross-linked structure as well as preparation method and application of polyimide film

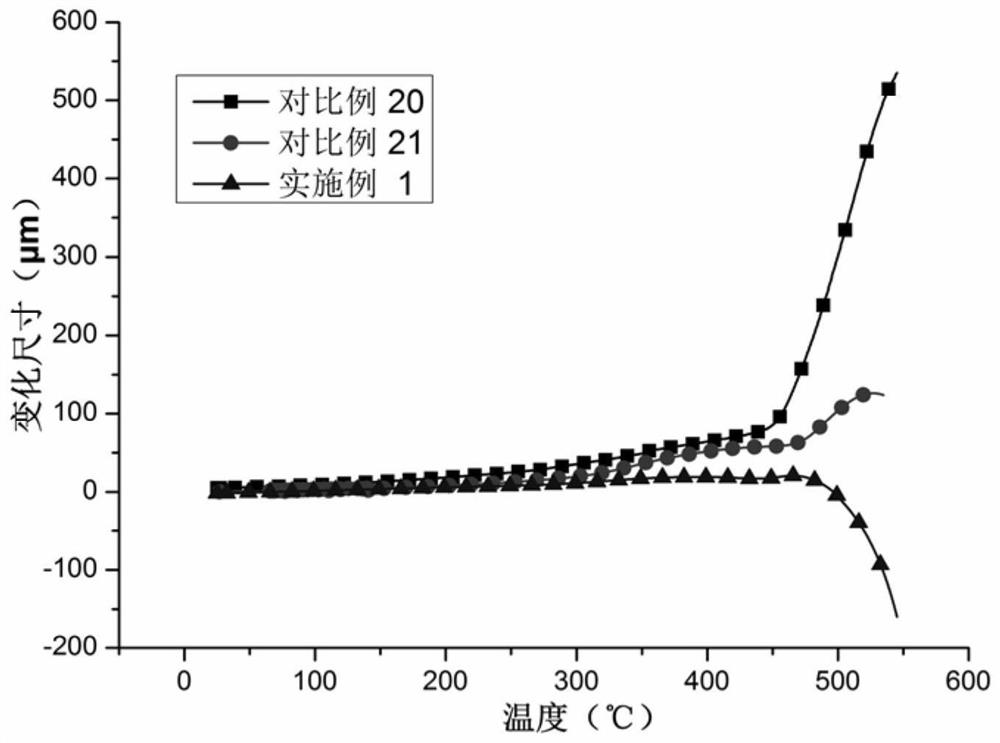

A technology of polyimide film and cross-linked structure, applied in identification devices, instruments and other directions, can solve the problems of poor thermal stability and large thermal expansion coefficient of polyimide, and achieves simple preparation method, reduced CTE, and improved vitrification. Effect of transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

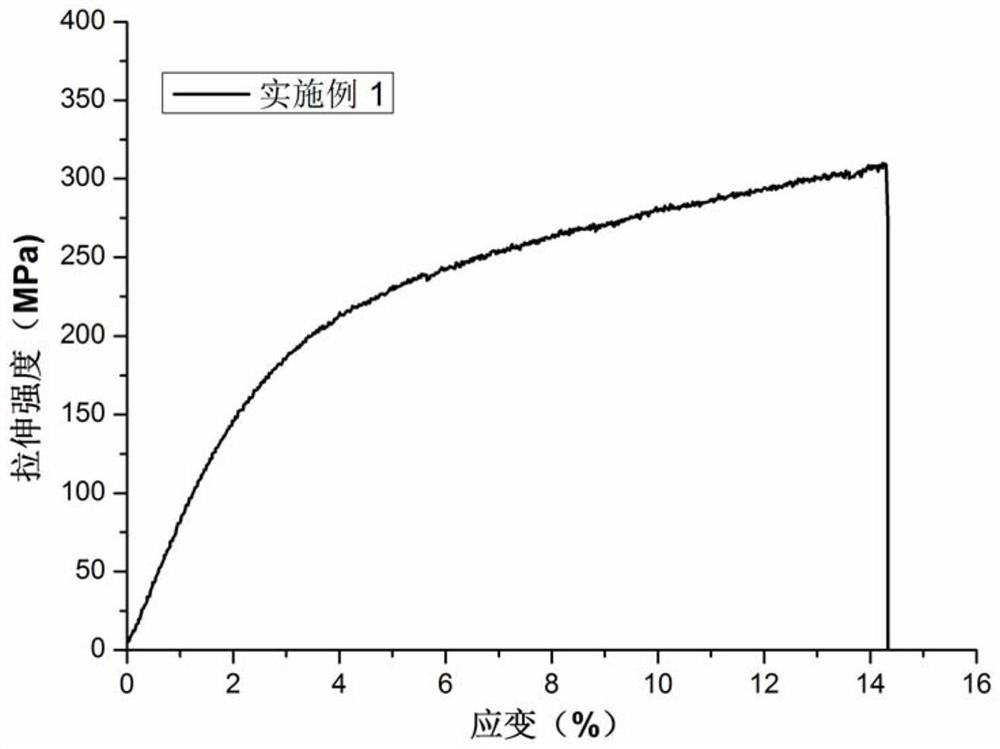

Embodiment 1

[0027] This example realizes the preparation of polyimide film with synergistic cross-linked structure in the following ways:

[0028] 1. In the reactor, add solvent N-methylpyrrolidone 261.13g, turn on mechanical stirring, add diamine compound 3,5-diaminobenzoic acid 1.11g and p-phenylenediamine 12.38g, control temperature to 30℃, Stir for 30min, add dianhydride compound 3,3'4,4'-biphenyltetracarboxylic dianhydride 35.31g after complete dissolution, the viscosity of the reaction solution gradually increases, after 6 hours of reaction, it is heated to 50 ℃, and after 3 hours of reaction , lowered to 25° C., added 0.94 g of end-capped compound trimellitic anhydride, reacted for 5 hours, stopped stirring, and obtained a polyamic acid solution with an apparent viscosity of 6000 cps.

[0029] 2. Use a filter membrane with a pore size of 0.3 μm to filter the polyamic acid solution obtained in step 1 through positive pressure. After vacuum defoaming, it is uniformly coated on a clea...

Embodiment 2

[0031] 1. In the reactor, add the solvent N-methylpyrrolidone 312.72g, turn on the mechanical stirring, then add the diamine compound 3,5-diaminobenzoic acid 1.81g and p-phenylenediamine 20.16g, control the temperature to 30 ℃, Stir for 30min, add dianhydride compound 3,3'4,4'-biphenyltetracarboxylic dianhydride 35.31g and pyromellitic dianhydride 15.79g after completely dissolving, the viscosity of the reaction solution gradually increases, after 6 hours of reaction, The temperature was raised to 50°C, and after 3 hours of reaction, the temperature was lowered to 25°C, and 2.29 g of end-capped compound trimellitic anhydride was added, reacted for 5 hours, and stopped stirring to obtain a polyamic acid solution with an apparent viscosity of 7000 cps.

[0032] 2. Use a filter membrane with a pore size of 0.3 μm to filter the polyamic acid solution obtained in step 1 through positive pressure. After vacuum defoaming, it is uniformly coated on a clean substrate with a predetermine...

Embodiment 3

[0034] 1. In the reactor, add solvent N-methylpyrrolidone 265.74g, turn on mechanical stirring, then add diamine compound 4,4-diaminobiphenyl-3,3-tetracarboxylic acid 1.99g and p-phenylenediamine 12.38g, control the temperature at 30℃, stir for 30min, add dianhydride compound 3,3'4,4'-biphenyltetracarboxylic dianhydride 35.31g after complete dissolution, the viscosity of the reaction solution gradually increases, after 8 hours of reaction, the temperature rises At 50°C, after 5 hours of reaction, the temperature was lowered to 25°C, 0.94 g of end-capped compound trimellitic anhydride was added, the reaction was performed for 6 hours, and stirring was stopped to obtain a polyamic acid solution with an apparent viscosity of 6000cps.

[0035] 2. Use a filter membrane with a pore size of 0.3 μm to filter the polyamic acid solution obtained in step 1 through positive pressure. After vacuum defoaming, it is uniformly coated on a clean substrate with a predetermined thickness, and pre-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com