Polycation anti-swelling agent as well as preparation method and application thereof

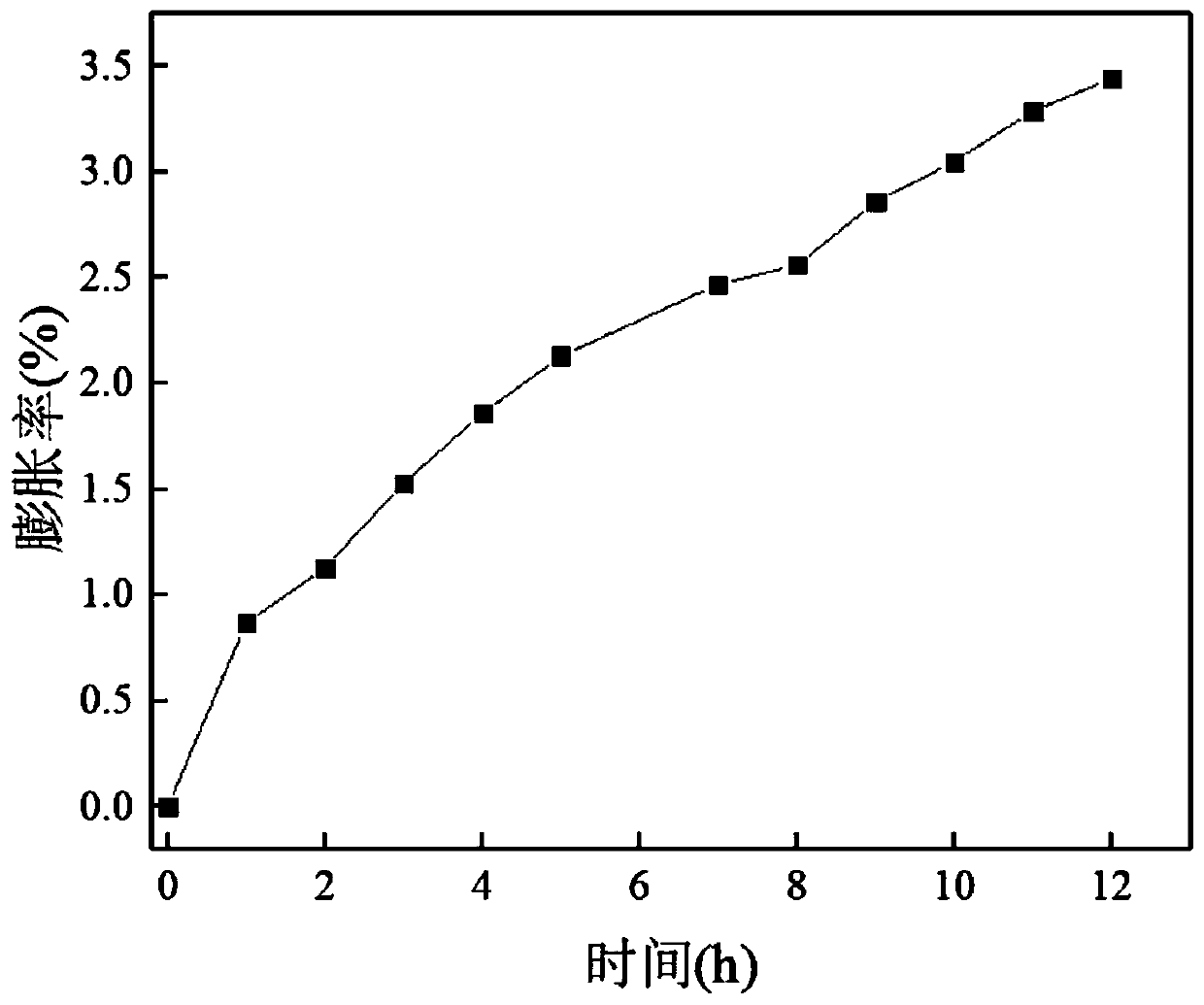

A multi-cation, anti-swelling agent technology, applied in the preparation of carboxylic acid halide, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of increased water injection pressure, reduced oil recovery, and decreased oil permeability. , to extend the water injection cycle, prevent hydration swelling, and reduce oil layer damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

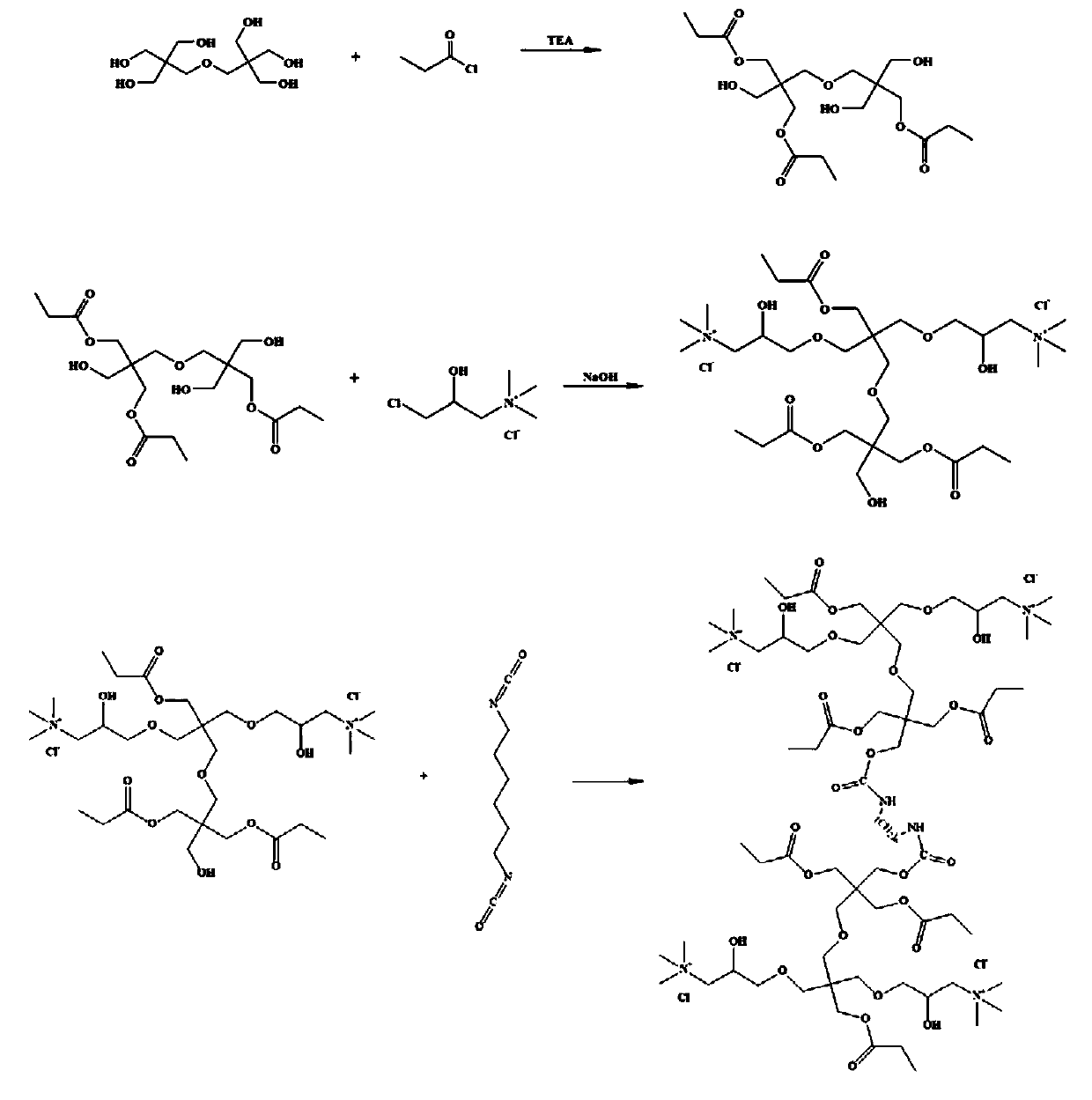

[0026] Concrete, a kind of preparation method of polycation antiswelling agent, comprises the following steps:

[0027] (1) Add dipentaerythritol and propionyl chloride into a three-necked flask, wherein the molar ratio of dipentaerythritol and propionyl chloride is 1:(2.8-3). After the addition is complete, stir the reaction at 35-45°C for 2-4 hours, and cool to room temperature. Neutralize with sodium hydroxide solution, wherein the concentration of the sodium hydroxide solution is 5% (mass fraction). Wash with water, extract with an organic solvent, and distill off the solvent under reduced pressure to obtain viscous liquid intermediate Ⅰ.

[0028] (2) Add the viscous liquid intermediate I obtained in step (1) into a four-necked flask, and the added amount of the viscous liquid intermediate I is 0.025 mol. Then the first solvent dimethyl sulfoxide (DMSO) was added into the four-neck flask in an amount of 130 mL. After it is completely dissolved, powdered sodium hydroxide...

Embodiment 1

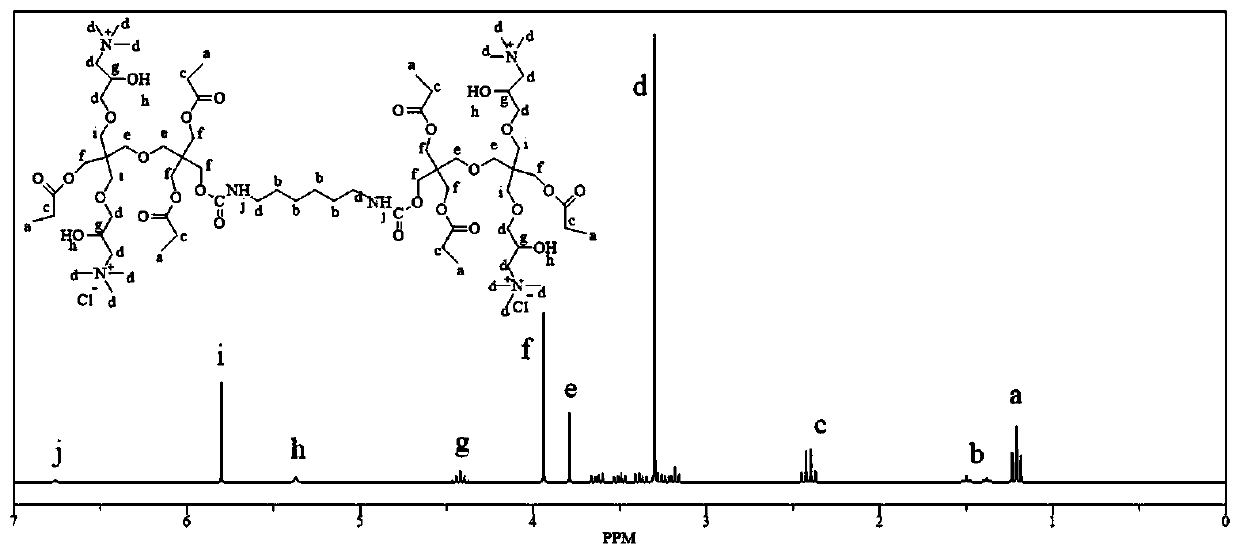

[0033] Add dipentaerythritol and propionyl chloride into a three-necked flask at a molar ratio of 1:2.8. After the addition is complete, stir and react at 40°C for 3h, and cool to room temperature. Neutralize with 5% (mass fraction) sodium hydroxide solution, wash with water, extract with organic solvent, and distill off the solvent under reduced pressure to obtain viscous liquid intermediate I. Take 0.025mol of the viscous liquid intermediate I and add it to a four-necked flask, then add 130mL dimethyl sulfoxide (DMSO) into the four-necked flask, and after it is completely dissolved, add 4g of powdered sodium hydroxide and stir the reaction at 35°C 0.5h, then add 0.05mol 3-chloro-2-hydroxypropyltrimethylammonium chloride into the solution containing dimethyl sulfoxide and other solvents, raise the temperature to 80°C, react for 6h, and suction filter the above solution, Intermediate II was obtained as a solid product. Add 0.02mol of solid product Intermediate II to 21.93g of...

Embodiment 2

[0035]Add dipentaerythritol and propionyl chloride into a three-necked flask at a molar ratio of 1:2.85. After the addition is complete, stir and react at 40°C for 3h, and cool to room temperature. Neutralize with 5% (mass fraction) sodium hydroxide solution, wash with water, extract with organic solvent, and distill off the solvent under reduced pressure to obtain viscous liquid intermediate I. Take 0.025mol of the viscous liquid intermediate I and add it to a four-necked flask, then add 130mL dimethyl sulfoxide (DMSO) into the four-necked flask, and after it is completely dissolved, add 4g of powdered sodium hydroxide and stir the reaction at 35°C 0.5h, then add 0.05mol 3-chloro-2-hydroxypropyltrimethylammonium chloride into the solution containing dimethyl sulfoxide and other solvents, raise the temperature to 80°C, react for 6h, and suction filter the above solution, Intermediate II was obtained as a solid product. Add 0.02mol of solid product Intermediate II to 21.93g of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap