Electro-tinning additive and preparing method and application method thereof

An additive and electroplating tin technology, applied in the field of electroplating tin additives and its preparation, can solve the problems of high tank changing frequency, low safety, low production efficiency, etc., and achieve extended tank life, excellent electroplating performance, and good anti-oxidation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

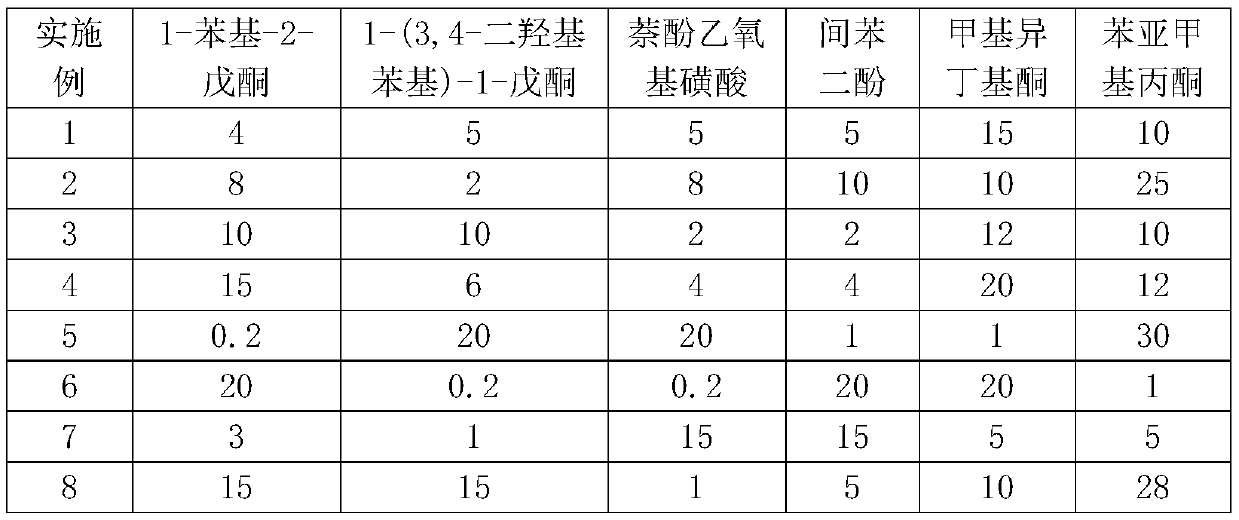

Embodiment 1-11

[0030] A preparation method of an electroplating tin additive, comprising the following steps:

[0031] (1) Add water to the container;

[0032] (2) In the case of stirring, add 1-phenyl-2-pentanone in proportion until completely dissolved;

[0033] (3) In the case of stirring, add antioxidants in proportion until completely dissolved;

[0034] (4) While stirring, add 1-(3,4-dihydroxyphenyl)-1-pentanone in proportion until completely dissolved;

[0035] (5) In the case of stirring, add the brightener in proportion until it is completely dissolved;

[0036] (6) In the case of stirring, add naphthol ethoxy sulfonic acid in proportion until completely dissolved;

[0037] (7) under the situation of stirring, add resorcinol in proportion until fully dissolved;

[0038] (8) Add water to the required amount, and stir well after completion.

[0039] The water is deionized water, the antioxidant is one of diisobutyl ketone and methyl isobutyl ketone, and the brightener is benzylid...

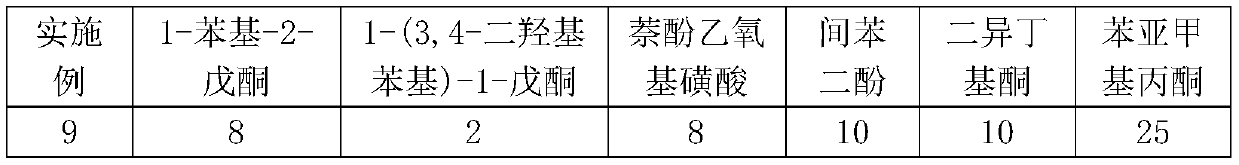

Embodiment 9

[0043] The concentration of each component in embodiment 9 is as shown in table 2:

[0044] Table 2: Each component content table (g / L) in the electroplating tin additive of embodiment 9

[0045]

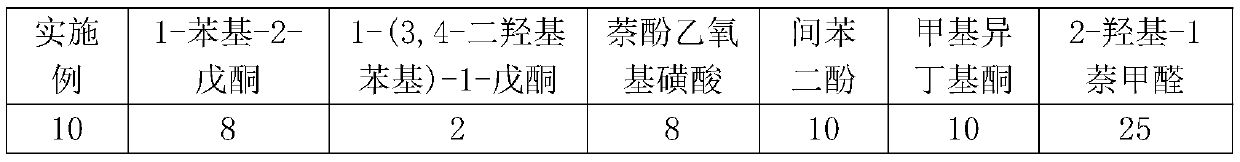

Embodiment 10

[0046] The concentration of each component in embodiment 10 is as shown in table 3:

[0047] Table 3: Each component content table (g / L) in the electroplating tin additive of embodiment 10

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com