Horizontal well film-coated proppant staged fracturing yield testing method

A technology of staged fracturing and testing methods, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of difficult identification technology, small difference in tracer concentration, short validity period of post-fracture test sampling analysis, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

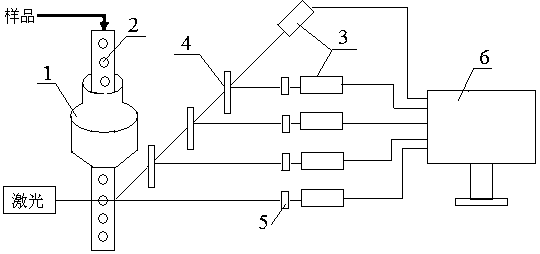

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for testing the yield of horizontal well film-coated proppant staged fracturing, including the following steps:

[0041] Step 1) Select different types of tracers for different fracturing stages according to the number of fracturing stages in the horizontal well;

[0042] Step 2) Mark different types of tracers in the polymer to obtain different types of quantum dot polymers, and then form different types of quantum dot polymer coating proppants with different types of quantum dot polymers and proppants;

[0043] Step 3) During the fracturing construction of each fracturing stage, part of the proppant is first added along with the fracturing fluid, then a quantum dot polymer coating proppant is added, and the rest of the proppant is added at last. The amount added to each fracturing stage Quantum dot polymer coating proppant concentration is the same;

[0044] Step 4) During the production of the lower pump layer, measure the liquid ou...

Embodiment 2

[0052] This embodiment provides a method for testing the yield of horizontal well film-coated proppant staged fracturing, including the following steps:

[0053] Step 1) Select the same amount and type of tracer according to the number of staged fracturing stages of the horizontal well;

[0054] Step 2) Mark different types of tracers in the polymer to obtain different types of quantum dot polymers, and then coat different types of quantum dot polymers on the surface of the proppant to form different types of quantum dot polymer coating supports agent;

[0055] Step 3) During the fracturing construction, use the sand tank truck to load the quantum dot polymer coating proppant, add the sand bucket of the sand mixer truck, add a quantum dot polymer coating proppant with the fracturing fluid for each fracturing section, and add a quantum dot polymer coating proppant with the fracturing fluid. The concentration of quantum dot polymer coating proppant added to each fracturing stag...

Embodiment 3

[0063] On the basis of Example 1, this example provides a test method for staged fracturing production of horizontal well film-coated proppants, the polymers include oil-soluble polymers and water-soluble polymers, and the tracers are respectively marked The oil-soluble polymer and the water-soluble polymer are post-mixed and evenly coated on the surface of the proppant, wherein the molar ratio of the oil-soluble polymer and the water-soluble polymer is 1:1.

[0064] Because polymers include both water-soluble polymers and oil-soluble polymers, they will not dissolve during the injection of fracturing fluid. Only after being added to the formation, as the oil well is produced, it will slowly dissolve when it encounters crude oil and formation water. The coating agent on the surface of the agent is oil-soluble and water-soluble at the same time, the quantum dot tracer marker 2 marked on the oil-soluble polymer exists in the oil phase, and the quantum dot tracer marker 2 marked o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com