Preparation method and application of metal-metal sulfide heterojunction catalyst

A metal sulfide, heterojunction technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of low HOR performance, and achieve the effects of optimizing binding energy, reducing production costs, and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a metal-metal sulfide heterojunction catalyst, comprising the following steps: preparing a metal sulfide precursor through a colloid synthesis method, and calcining the precursor in a reducing atmosphere to obtain the heterojunction catalyst.

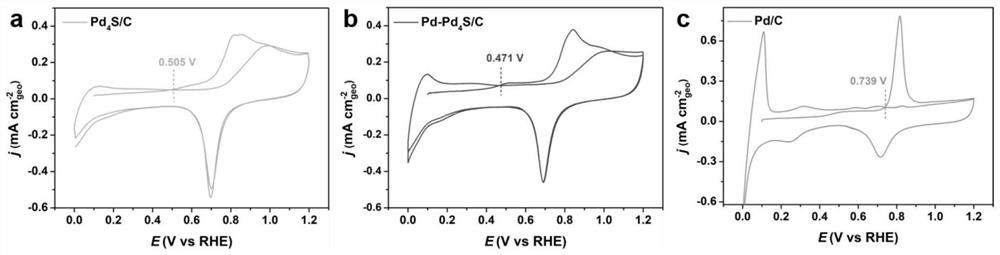

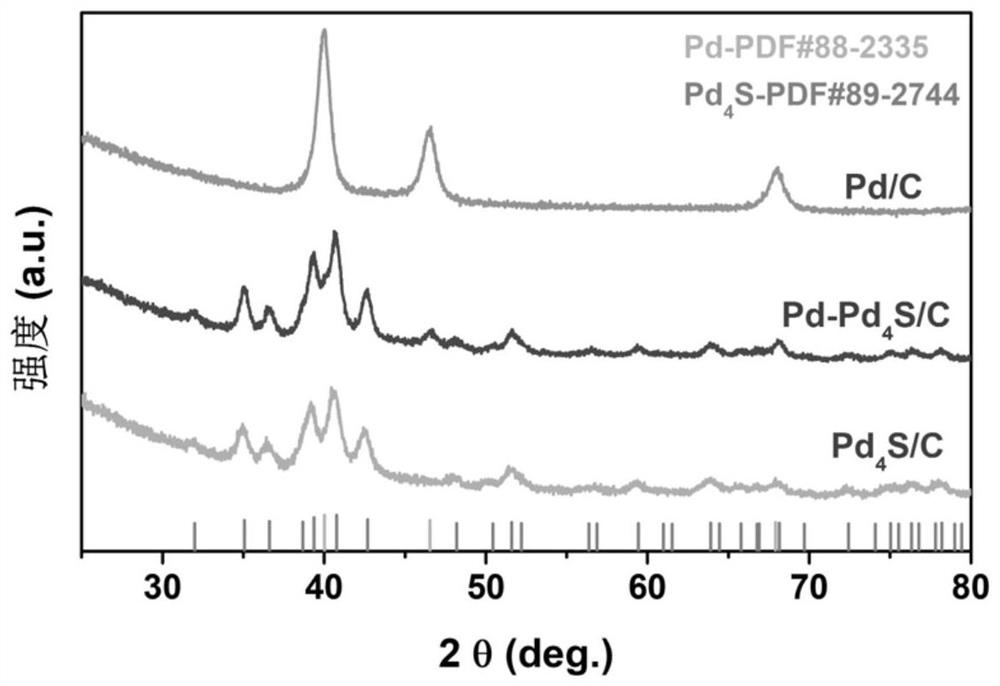

[0033] Further, the metal sulfide is selected from Pd 4 S, Rh 2 S 3 or RuS 2 , preferably, Pd 4 S.

[0034] Further, the preparation method of the metal sulfide precursor includes: dissolving metal acetylacetonate, sulfur powder, solvent, and carbon carrier together, heating and reacting at 280-350°C for 60-120min; preferably, at 300 Heating and reacting at ℃ for 60 minutes; further, the solvent is selected from pure oleylamine, oleylamine and octadecene, oleylamine and dodecylamine, oleylamine and oleic acid, preferably pure oleylamine; further, The carbon carrier is selected from the carbon carrier XC-72 carbon, activated carbon, graphene, reduced graphene oxide, acetylene blac...

Embodiment 1

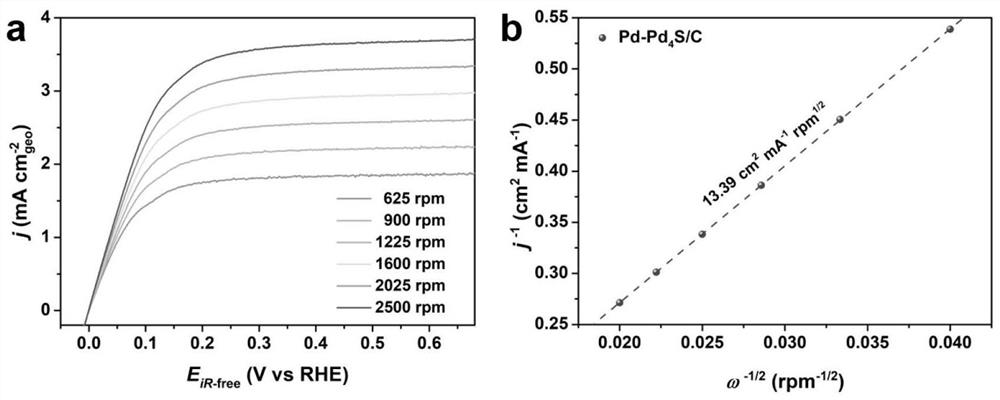

[0043] Pd-Pd 4 The preparation method of S / C heterojunction catalyst:

[0044] Oleylamine (5.0 mL), sulfur powder (16.0 mg), palladium acetylacetonate (30.4 mg) and XC-72 carbon powder (30.0 mg) were added to a three-necked flask and magnetically stirred. Subsequently, the temperature of the solution was increased to 100° C., and the reaction was performed in vacuum for 20 minutes to remove moisture and oxygen in the reaction system. After refilling with nitrogen, the temperature was further raised to 300°C, kept at this temperature for 60 minutes, and cooled to room temperature naturally. Then the samples were collected by centrifugation, washed by adding n-hexane and ethanol successively, and dried under vacuum at room temperature. Finally, the dried sample was put into the quartz boat in the center of the tube furnace, and calcined in a reducing atmosphere with a volume ratio of nitrogen and hydrogen of 20:1 at a temperature of 400°C for 60 minutes to obtain Pd-Pd 4 S / C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com