Dimension reduction method of three-dimensional perovskite

A perovskite, three-dimensional technology, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve problems such as slow cooling, material morphology, size, and chemical composition difficulties, crystallization method dependence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

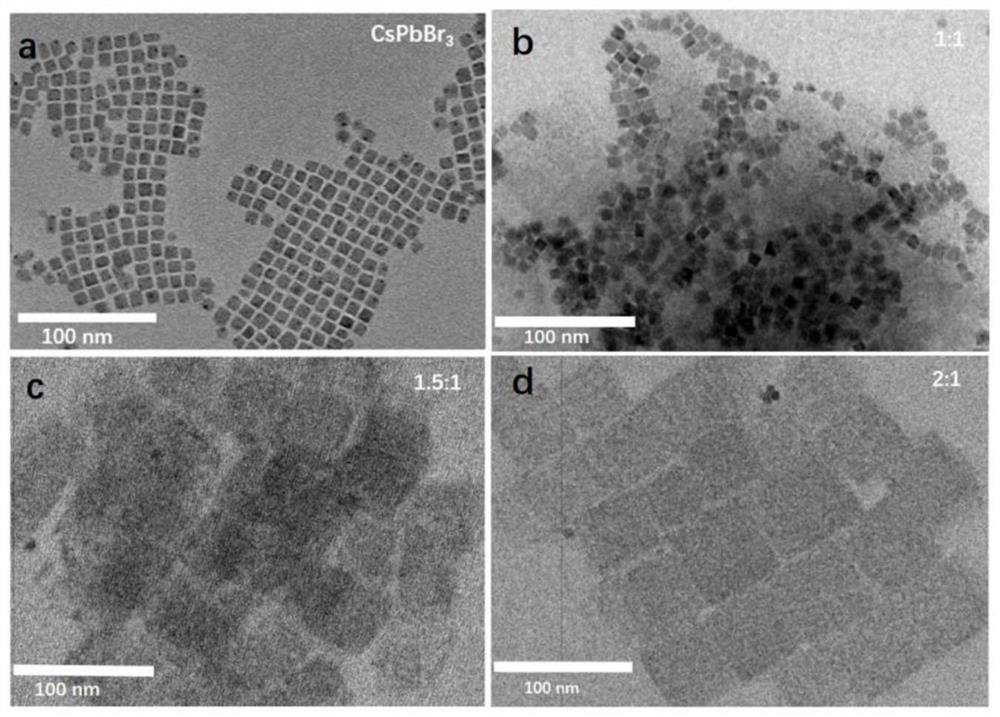

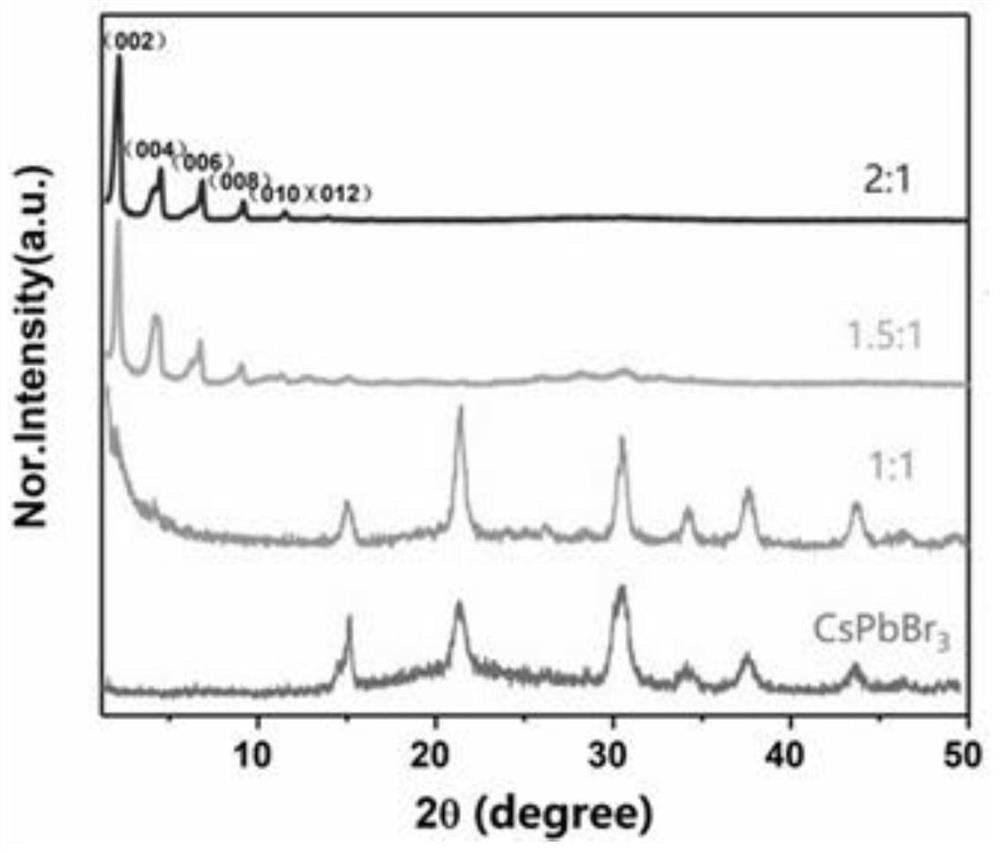

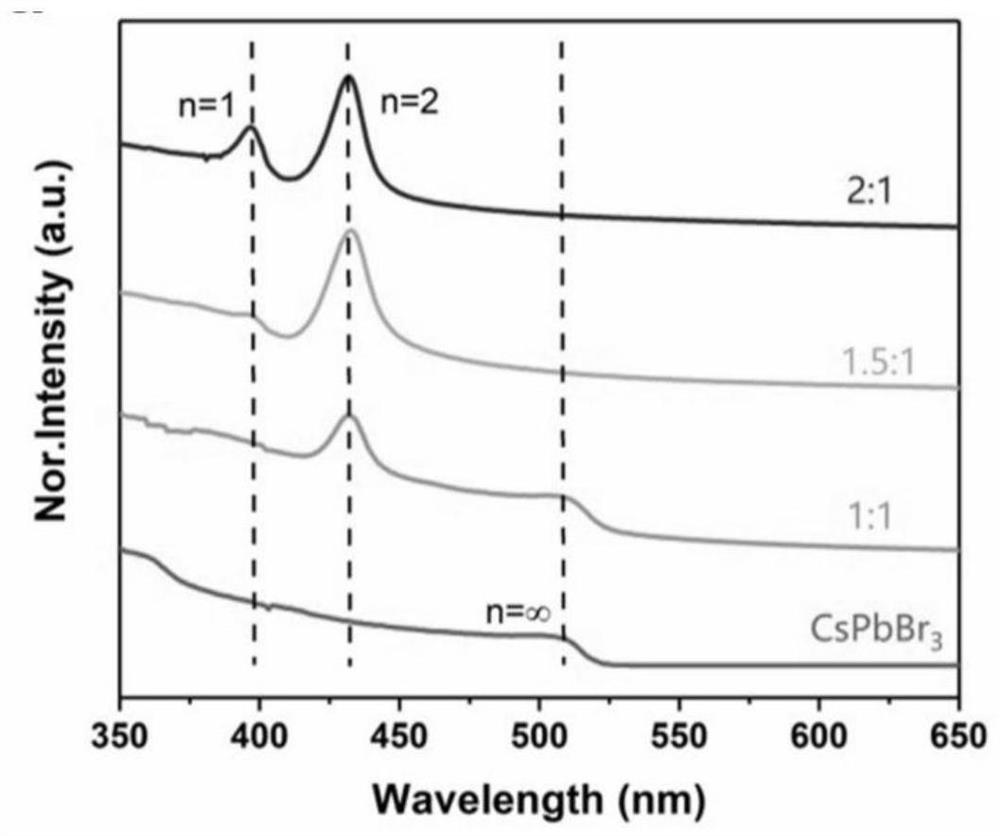

Embodiment 1

[0027] S1: Put 2.5ml oleic acid, 30ml octadecene and 0.814g cesium carbonate into a 100ml three-necked bottle A;

[0028] S2: vacuumize the three-necked bottle A containing the mixture of oleic acid, octadecene and cesium carbonate for 1 hour;

[0029] S3: keeping the mixture of oleic acid, octadecene and cesium carbonate at 150°C under nitrogen atmosphere for 3 hours until the mixture of oleic acid, octadecene and cesium carbonate forms a clear precursor solution;

[0030] S4: Put 0.138g of lead bromide, 0.069g of magnesium bromide, 1ml of oleylamine, 1ml of oleic acid and 10ml of octadecene into a 100ml three-necked bottle B;

[0031] S5: Vacuum the three-necked bottle B, heat the mixture of lead bromide, magnesium bromide, oleylamine, oleic acid and octadecene to 120°C under vacuum, and keep this state for 1 hour to obtain a mixed solution A;

[0032] S6: Rapidly heat up the mixed solution A at 120°C to 185°C, and inject 1ml of the precursor solution into it to obtain the...

Embodiment 2

[0035] Using the same process as in Example 1, the difference is that the amount of magnesium bromide in step 2 of Example 1 is changed to 0.104g, and other conditions remain the same.

Embodiment 3

[0037] Using the same process as in Example 1, the difference is that the amount of magnesium bromide in step 2 of Example 1 is changed to 0.138g, and other conditions remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com