Dust particle size and concentration nondestructive on-line detection device and method

A detection device and particle size technology, used in measurement devices, particle size analysis, particle suspension analysis, etc., can solve the problems of inaccurate detection results, adhesion to the pipe wall, dust loss, etc., and achieve accurate time-of-flight detection results. The effect of avoiding inaccurate detection and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

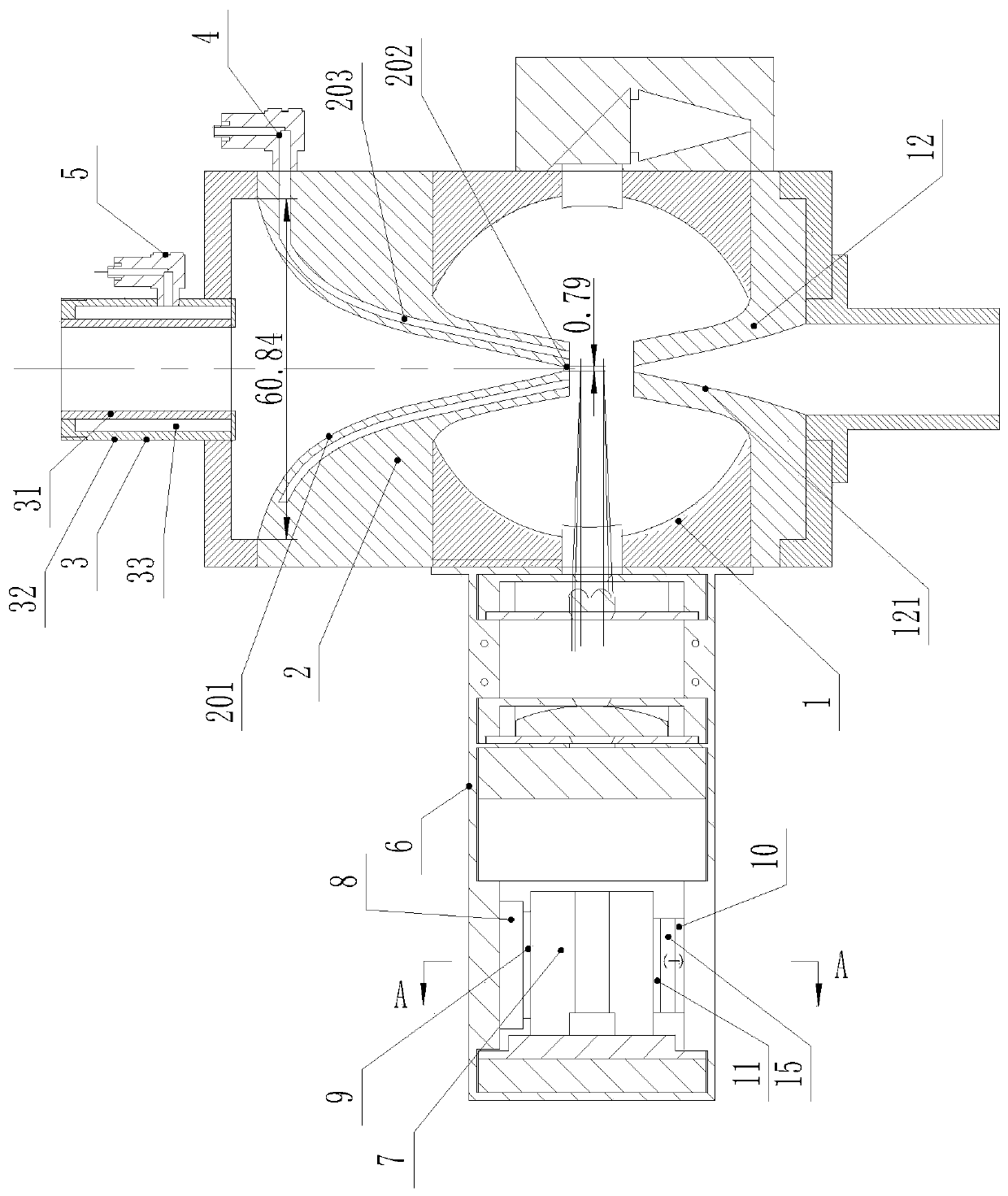

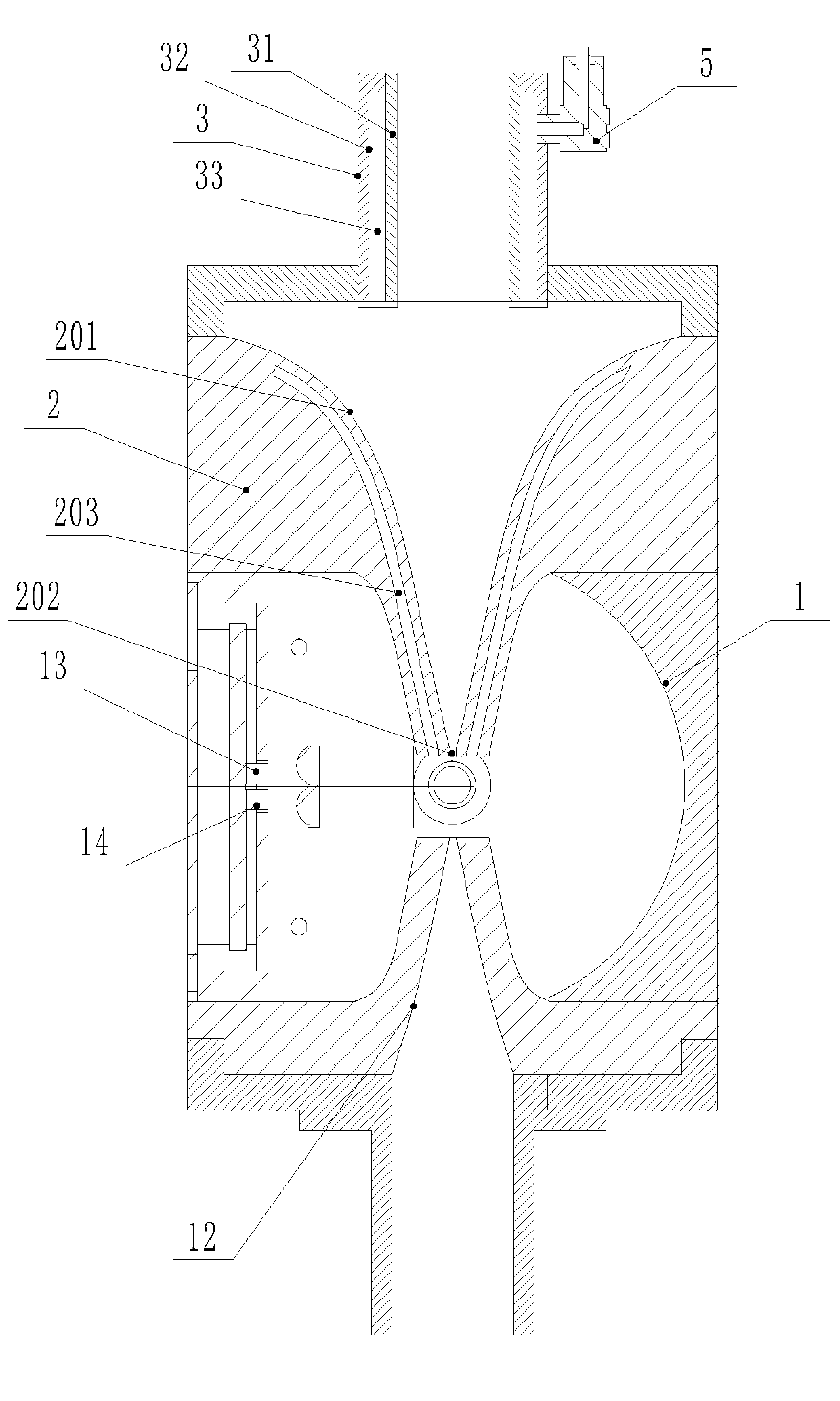

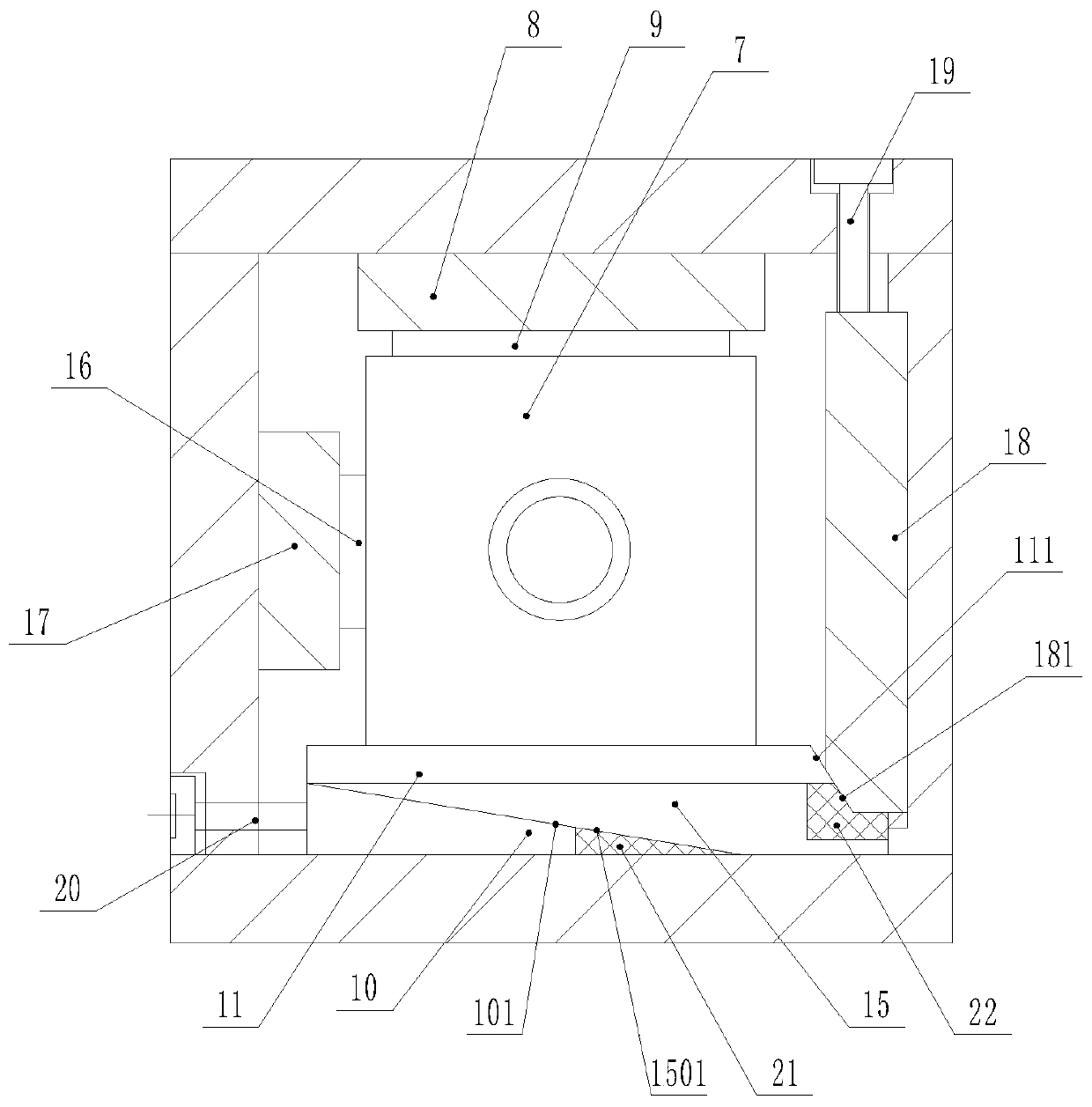

[0031] Such as Figure 1 to Figure 3 As shown, a non-destructive online detection device for dust particle size and concentration includes a detection chamber 1. The detection chamber 1 is provided with a particle acceleration nozzle 2 and an air outlet connector 12 communicating with the detection chamber 1. The particle acceleration nozzle 2 A sample gas channel and a ring-shaped zero gas channel surrounding the sample gas channel are provided; the detection chamber 1 is provided with an intake pipe 3 communicating with the particle acceleration nozzle 2 and a first zero gas connector 4 communicating with the zero gas channel, A fixed cover 6 is installed on the detection chamber 1, and the fixed cover 6 is equipped with a light source fixing seat 7 and a light inlet lens assembly. The detection chamber 1 is provided with a light output lens assembly and two detectors for detecting scattered light signals. The photodetector is convenient for description. The two photodetector...

Embodiment 2

[0038] A non-destructive online detection method for dust particle size and concentration, which uses the aforementioned non-destructive online detection device;

[0039] After the sampled gas enters the sintered inner tube, it passes through the particle acceleration nozzle 2. The sample gas passes through the arc-shaped contraction channel and then accelerates and ejects from the throat channel to form a high-speed particle stream; at the same time, the clean zero gas passes through the first zero gas connector 4 and the second zero gas joint 5 enter the zero gas channel and the zero gas chamber. The zero gas of the zero gas chamber enters the sintered inner tube through the micro-holes on the sintered inner tube to form an in-tube protective air curtain. The gas wraps the particle airflow beam, and the particle airflow beam is discharged after passing through the expansion channel of the air outlet connector 12; the total light beam generated by the light source holder 7 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com