Cutter residual life prediction method based on machine learning regression algorithm

A technology of life prediction and regression algorithm, applied in machine learning, prediction, instrument and other directions, can solve the problems of low accuracy, narrow scope of application, conservative tools, etc., to achieve high training accuracy, good generalization performance, and accurate prediction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

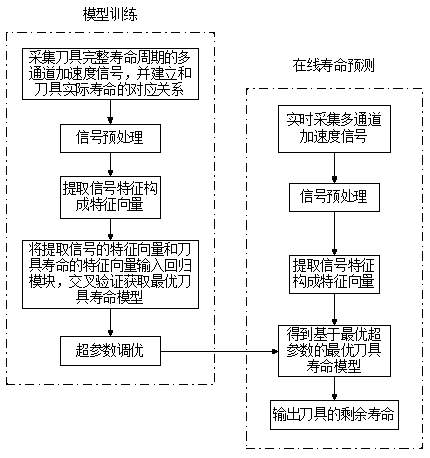

[0028] Such as figure 1 As shown, this embodiment includes two parts, model training and online life prediction, and the model training part includes the following steps:

[0029] 100. Use the 3-channel acceleration sensor to collect and store the acceleration signals of the three key points of the tool machine under a complete life cycle of the tool, and use the online automatic measurement system for tool wear to obtain the real-time remaining life of the tool. The method for obtaining the remaining life of the tool can refer to Wang Qiang, Li Yingguang, Hao Xiaozhong, etc. published the paper "Dynamic Prediction Method of CNC Machining Tool Life Based on Online Learning" in the journal "Aviation Manufacturing Technology" in 2019. one-to-one corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com