Method for preparing liquid crystal elastomer intelligent material with three-dimensional reversible drive

A technology for liquid crystal elastomers and smart materials, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems that the liquid crystal cells are not fully oriented, cannot produce reversible deformation, and the single domain is easy to disappear, and achieve stable orientation and method. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The liquid crystal elastomer used in this example is a liquid crystal elastomer that can undergo transesterification and contains biphenyl mesogens. Specifically, 4,4'-dihydroxybiphenyl diglycidyl ether and sebacic acid are used at a high temperature of 180 ° C. The liquid crystal elastomer obtained after melting, stirring, and heating for 4 hours.

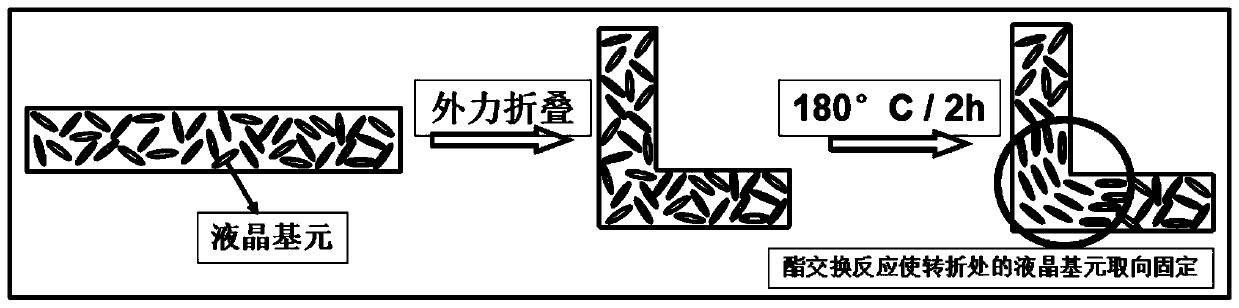

[0029] see figure 1 , specifying the process method for preparing liquid crystal elastomer smart materials with three-dimensional reversible drive of the present invention:

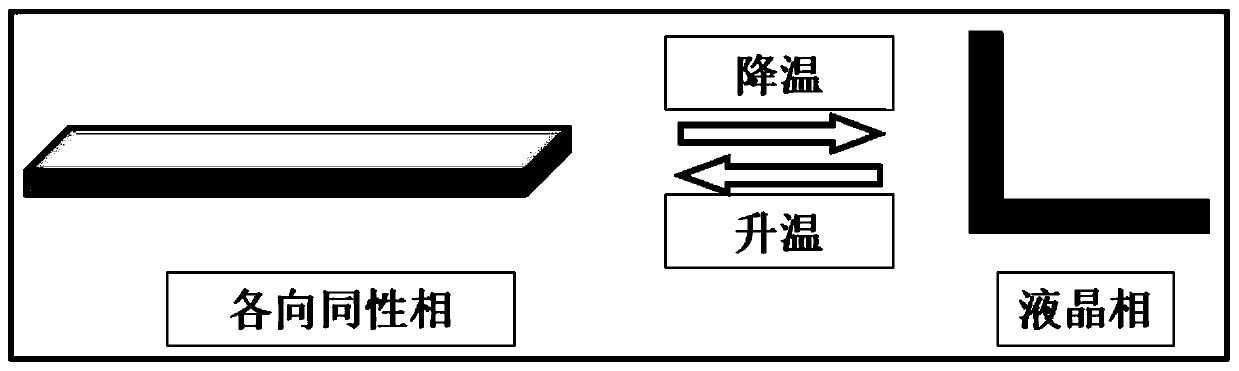

[0030] First, use external force to fold the strip-shaped spline of the three-dimensional reversibly driven liquid crystal elastomer smart material of the present invention into 90°, and at this time, the liquid crystal elements at the folded corners will be rearranged. Then, keep the folded deformation at high temperature (180°C) for 2 hours. During this process, the transesterification reaction in the liquid crystal elastomer will fix the orientatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com