A three-strand slab continuous casting tundish diversion structure and manufacturing method

A slab continuous casting and tundish technology, which is applied in the direction of manufacturing tools, casting equipment, casting molten material containers, etc., can solve the problems of hindering the reasonable flow of molten steel, small plug flow area, unbalanced flow, etc., and achieve the extension of the average residence time time, increasing plug flow area, eliminating the effect of breakdown flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

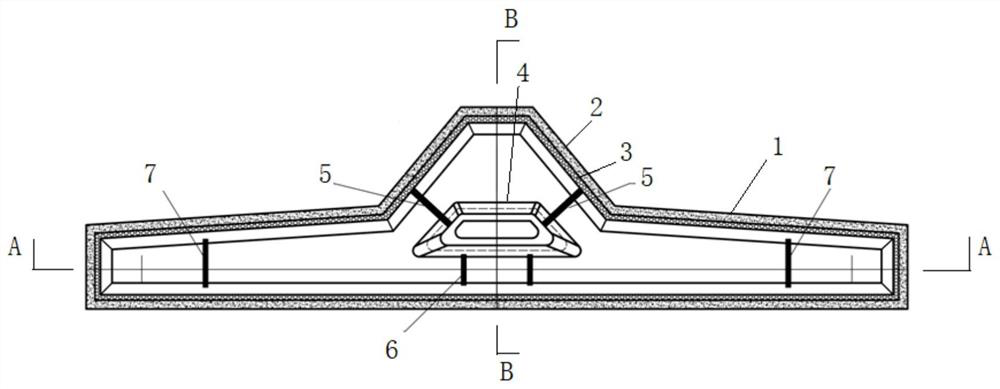

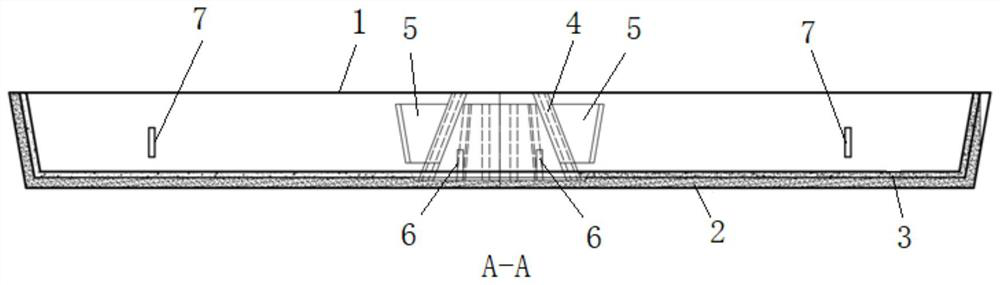

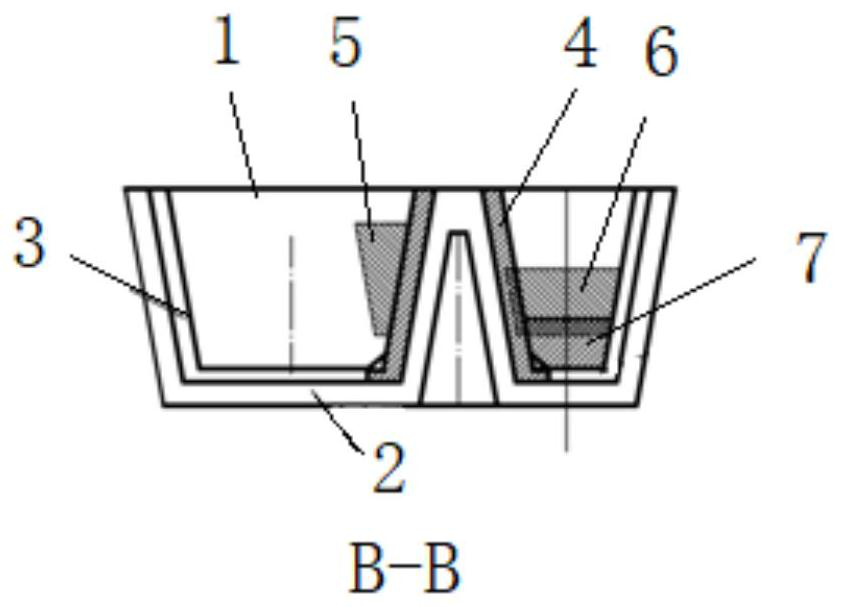

[0029] The three-strand slab continuous casting tundish diversion structure of the present invention is composed of a diversion island 4 , a diversion island retaining wall 5 , a diversion island retaining dam 6 and a tundish retaining dam 7 .

[0030] figure 1 , 2 , 3 show that the diversion island 4 is located in the middle of the tundish 1, and there are respectively molten steel flow channels between the front, rear, left and right sides of the diversion island 4 and the opposite inner wall of the tundish 1. There are diversion island retaining walls 5 in the molten steel flow channel between the diversion island 4 and the inner walls on both sides of the two opposite tundishes respectively, and a diversion island retaining dam 6 in the molten steel flow channel between the diversion island 4 and the front of the tundish 1, and the middle The two ends of bag 1 have tundish retaining dam 7 respectively. Wherein, the diversion island retaining wall 5 and the diversion isla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com