Circuit board material layer pre-laminating device and process

A technology of material layers and circuit boards, applied in printed circuit, thin material processing, printed circuit manufacturing, etc., can solve the problems of low production efficiency, high labor intensity, high error rate, etc., to improve product quality, save labor costs, The effect of strong automation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

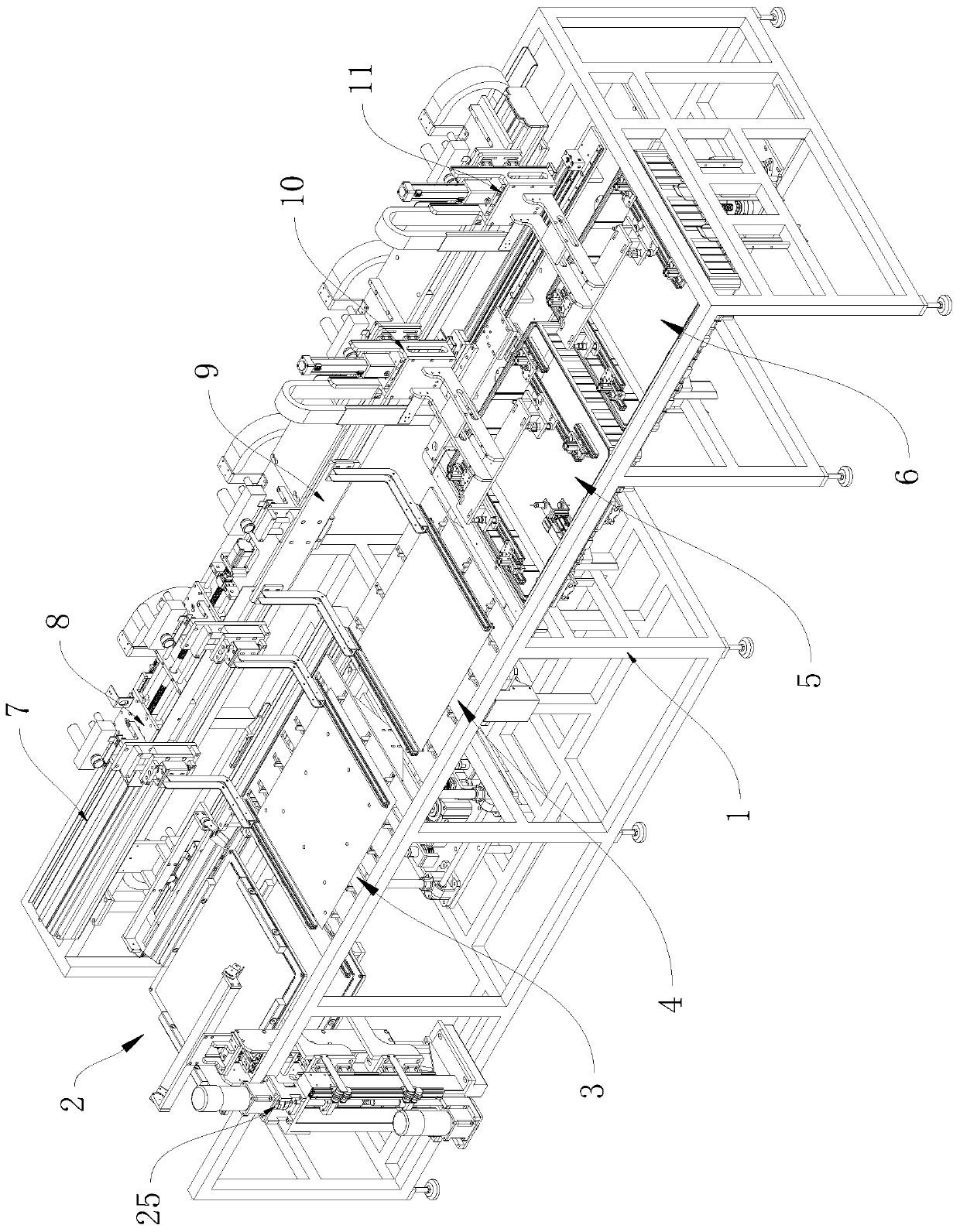

[0025] This embodiment proposes a kind of circuit board material layer pre-lamination equipment, combined with Figure 1 to Figure 11 As shown, it includes a frame 1, and the frame 1 is provided with a PP sheet feeding mechanism 2, a pre-stacking table 3, a transfer table 4, a core board feeding mechanism 5, and a paper-separated feeding mechanism from left to right. 6. The frame 1 is also provided with a sliding carrier 7 arranged left and right, and the sliding carrier 7 is provided with a PP retrieving manipulator 8, a core plate transfer manipulator 9, and a core plate in sequence from left to right. The material manipulator 10 and the paper-separated feeding manipulator 11, the PP retrieving manipulator 8 is used to pick up the PP sheet 100 from the PP sheet feeding mechanism 2 and place it on the pre-stacking platform 3, and the core board feeding manipulator 10 is used to pick up a core board from the core board feeding mechanism 5 and place it on the transfer table 4, ...

Embodiment 2

[0042] At present, for the raw materials of PP sheets placed in multiple layers, the commonly used method of retrieving materials is manual retrieving with the help of tools. This method of retrieving materials has low work efficiency and high labor costs, and cannot be used in the automatic equipment for pre-lamination of circuit board material layers. Promote apps.

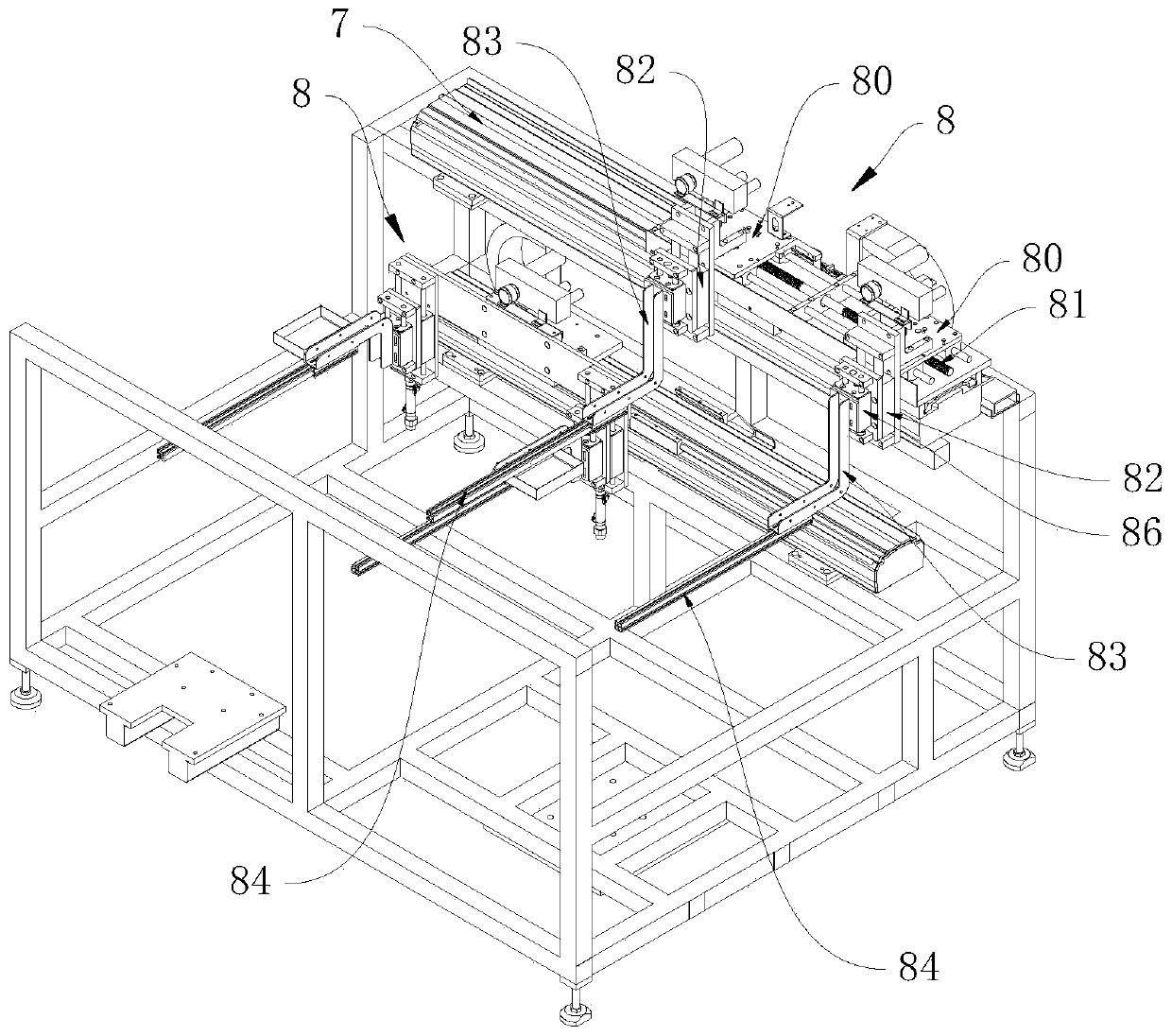

[0043] In this regard, this embodiment proposes a PP sheet retrieving device that can improve work efficiency, reduce labor costs, and have more automatic performance. Figure 1 to Figure 4 As shown, it includes a frame 1, the frame 1 is provided with a PP sheet feeding mechanism 2, a pre-stacking platform 3 and a sliding carrier 7, and a PP sheet 100 is placed on the PP sheet feeding mechanism 2, so A PP retrieving manipulator 8 is provided on the sliding carrier frame 7, and the PP reclaiming manipulator 8 includes a retrieving slide 80 and a retrieving translational drive mechanism 81 for driving the reclaimi...

Embodiment 3

[0065] At present, during the stacking process of multiple PP sheets, due to the influence of static electricity and other factors, two or more PP sheets are usually removed at the same time when taking materials. Once the number of PP sheets taken out is wrong, it will be directly Leading to the scrapping of circuit boards, the error rate and error rate are high, and it is difficult to meet the production requirements.

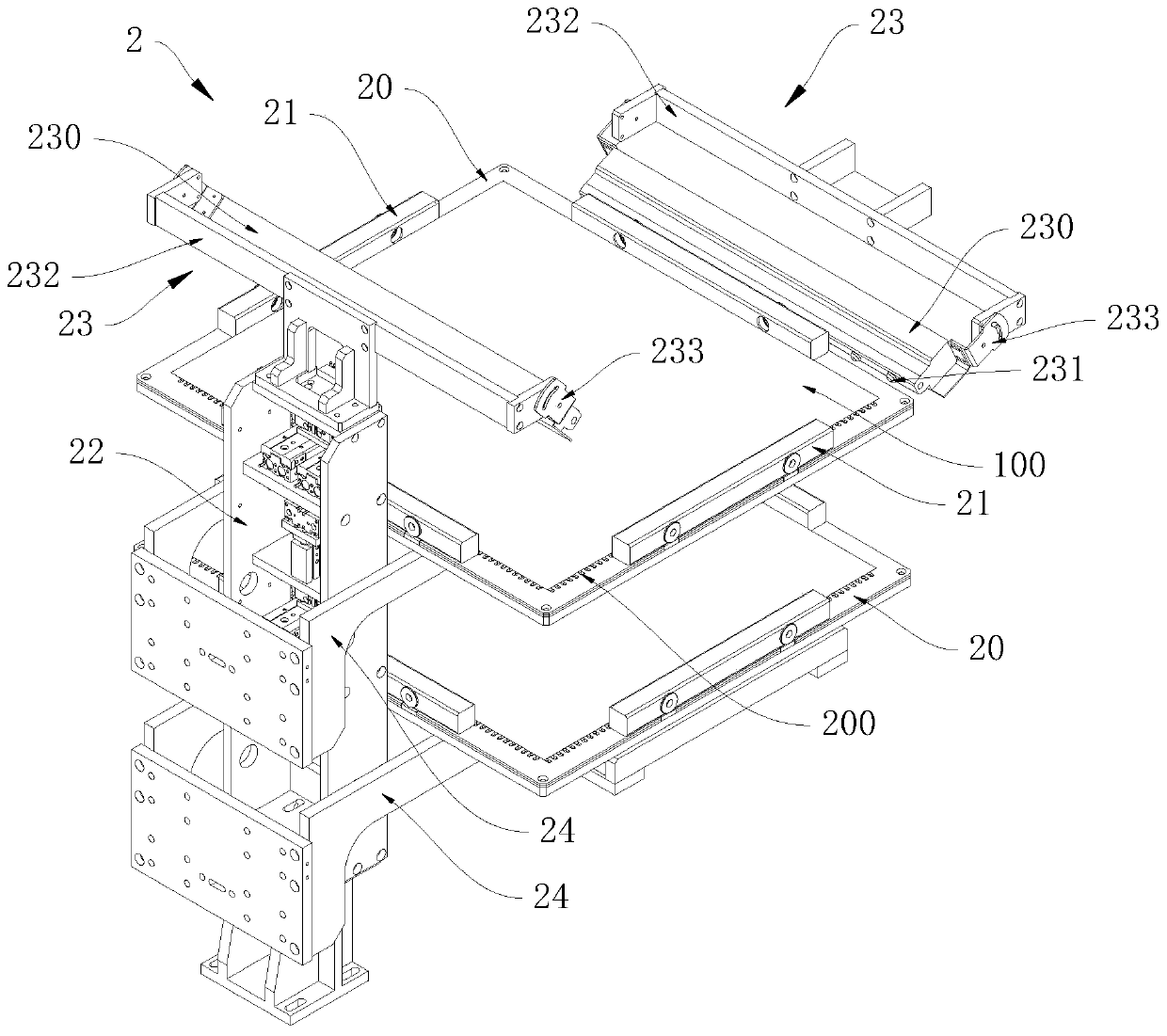

[0066] In this regard, this embodiment proposes a PP sheet feeding mechanism that can avoid taking multiple PP sheets by mistake due to electrostatic adsorption, thereby improving the accuracy of the feeding action and helping to improve the yield of circuit boards. Please refer to figure 1 and figure 2 , the PP sheet feeding mechanism 2 includes a square PP sheet feeding table 20, four stoppers 21 are fixed on the PP sheet feeding table 20, and the four stoppers 21 are respectively close to the four sides of the PP sheet feeding table 20. At the two edges,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com